Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

The Industrial Synchronous Belt is a high - performance power transmission component designed to meet the demanding requirements of modern industrial machinery. It stands out for its ability to provide precise and efficient power transfer, making it an essential part of various manufacturing and production processes.

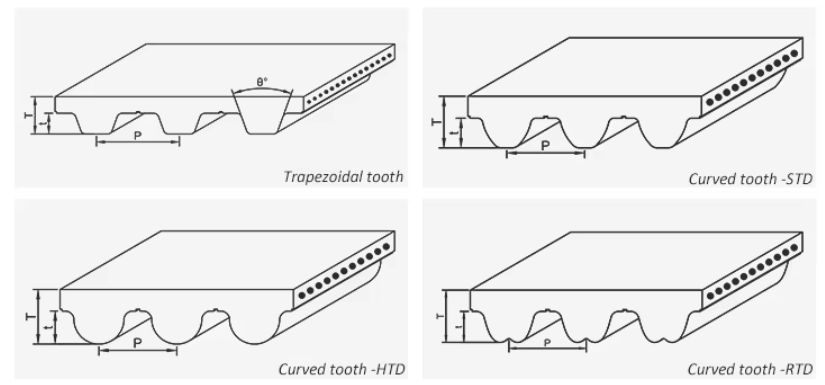

The most distinctive feature of the synchronous belt is its toothed design. The teeth on the inner surface of the belt are precisely shaped to mesh with the grooves on the corresponding synchronous pulleys. There are different tooth profiles available, such as the trapezoidal and curvilinear (e.g., HTD - High Torque Drive) profiles. The trapezoidal profile is a common choice for general - purpose applications. Its simple shape allows for easy manufacturing and provides good meshing characteristics. The curvilinear profiles, like HTD, are designed for high - torque and high - speed applications. They offer reduced vibration, noise, and higher power - transmission capacity due to their improved tooth - pulley engagement.

Rubber Compound: The body of the synchronous belt is made from high - quality rubber materials. Synthetic rubbers, such as neoprene or polyurethane, are commonly used. Neoprene is known for its excellent resistance to abrasion, oil, and ozone, making it suitable for industrial environments where the belt may be exposed to these elements. Polyurethane, on the other hand, offers high tensile strength, good flexibility, and better resistance to wear and chemicals. It can withstand the repeated flexing and tension during operation, ensuring a long service life.

Reinforcement Cords: Embedded within the rubber body are reinforcement cords. These cords are typically made of high - strength materials like aramid, glass fiber, or polyester. Aramid cords, for example, provide extremely high tensile strength, allowing the belt to transmit large amounts of power without stretching or breaking. The cords are evenly distributed along the length of the belt to ensure uniform load - bearing and prevent premature failure.

Industrial synchronous belts are designed to provide accurate and synchronous power transfer. Since the teeth of the belt mesh with the grooves of the pulley, there is no slippage, which is a common issue with other types of belts like V - belts. This precision ensures that the driven components operate at the exact speed required, which is crucial in applications such as CNC (Computer Numerical Control) machines, where precise control of speed and position is essential for high - quality manufacturing.

They offer high transmission efficiency, typically ranging from 95% to 98%. The minimal friction between the belt and pulley, due to the meshing design, reduces energy losses. This high efficiency not only saves energy but also reduces the operating costs of the machinery. In large - scale industrial operations, where multiple belts are used, the cumulative energy savings can be significant.

Synchronous belts can operate over a wide range of speeds and loads. They can handle high - speed applications, with some belts capable of running at speeds of up to several thousand revolutions per minute. At the same time, they can transmit high torque loads, making them suitable for heavy - duty industrial machinery such as large - scale conveyor systems, where they need to move heavy loads continuously.

The meshing action of the synchronous belt is relatively quiet compared to other power - transmission methods like chains. The rubber material of the belt helps to dampen vibrations, reducing noise levels. This makes synchronous belts an ideal choice for applications where a quiet working environment is required, such as in food and pharmaceutical manufacturing plants.

In manufacturing plants, synchronous belts are used in a variety of machinery. They are commonly found in automated assembly lines, where they are used to drive conveyor belts, robotic arms, and other precision - motion components. In the textile industry, they are used to drive spinning and weaving machines, ensuring consistent and accurate operation. In the printing industry, synchronous belts are used in printing presses to control the movement of paper and printing plates.

The packaging industry relies heavily on synchronous belts. They are used in packaging machines to control the movement of packaging materials, such as cardboard, plastic films, and labels. The precise power transmission of synchronous belts ensures that the packaging process is accurate and efficient, reducing waste and improving productivity. For example, in a bottling plant, synchronous belts are used to drive the conveyor systems that move bottles through the filling, capping, and labeling processes.

In the field of robotics and automation, synchronous belts play a crucial role. They are used in the joints of robotic arms to provide smooth and precise movement. The high - speed and high - torque capabilities of synchronous belts allow robots to perform complex tasks with accuracy and speed. They are also used in automated guided vehicles (AGVs) to drive the wheels, enabling precise movement within a factory or warehouse environment.

Synchronous belts offer a compact power - transmission solution. Compared to some other power - transmission methods, such as gears or chain drives, they require less space for installation. This is especially beneficial in modern industrial machinery, where space is often at a premium. The compact design also allows for more flexible machine design, as the belts can be routed in various ways to fit the available space.

They require relatively low maintenance. Since there is no slippage, there is less wear and tear on the belt and pulley. Regular inspection for signs of wear, such as cracking of the rubber or fraying of the cords, is usually sufficient. There is no need for frequent lubrication, as in the case of chain drives, which reduces maintenance costs and downtime. In addition, the long service life of synchronous belts means that they do not need to be replaced as frequently as some other types of belts.

Although the initial cost of a synchronous belt may be higher than that of some other types of belts, it is cost - effective in the long run. Their high efficiency, long service life, and low maintenance requirements result in lower overall operating costs. The precise power transmission also reduces the risk of product defects and machine breakdowns, which can lead to significant savings in production losses.

In conclusion, the Industrial Synchronous Belt is a versatile and reliable power - transmission component that offers numerous advantages in modern industrial applications. Its unique design and features make it an ideal choice for a wide range of industries, where precision, efficiency, and durability are essential.

If you need any adjustments to the content, like adding more specific industry examples or technical details, please let me know. I'm happy to refine the product introduction for you.

Technical Data Sheet

| Type | Pitch | Tooth height | Belt thickess | Angle |

| MXL | 2.032 | 0.51 | 1.14 | 40 |

| XXL | 3.175 | 0.76 | 1.52 | 50 |

| XL | 5.08 | 1.27 | 2.3 | 50 |

| L | 9.525 | 1.91 | 3.6 | 40 |

| H | 12.7 | 2.29 | 4.3 | 40 |

| XH | 22.225 | 6.35 | 11.2 | 40 |

| XXH | 31.75 | 9.35 | 15.7 | 40 |

| T2.5 | 2.5 | 0.7 | 1.3 | 40 |

| T5 | 5 | 1.2 | 2.2 | 40 |

| T10 | 10 | 2.5 | 4.5 | 40 |

| T20 | 20 | 5 | 8 | 40 |

| AT5 | 5 | 1.2 | 2.7 | 50 |

| AT10 | 10 | 2.5 | 5 | 50 |

| AT20 | 20 | 5 | 8 | 50 |

| Gear code | Type | Pitch | Tooth height | Belt thickess |

| HTD | 3M | 3 | 1.17 | 2.4 |

| 5M | 5 | 2.06 | 3.8 | |

| 8M | 8 | 3.36 | 6 | |

| 14M | 14 | 6.02 | 10 | |

| 20M | 20 | 8.4 | 13.2 | |

| STPD/STS | S2M | 2 | 0.76 | 1.36 |

| S3M | 3 | 1.14 | 1.9 | |

| S4.5M | 4.5 | 1.71 | 2.81 | |

| S5M | 5 | 1.91 | 3.4 | |

| S8M | 8 | 3.05 | 5.3 | |

| S14M | 14 | 5.3 | 10.2 | |

| RPP/HPPD | Rpp2M | 2 | 0.76 | 1.36 |

| Rpp3M | 3 | 1.15 | 1.9 | |

| Rpp5M | 5 | 1.95 | 3.5 | |

| Rpp8M | 8 | 3.2 | 5.5 | |

| Rpp14M | 14 | 6 | 10 |

China Belt manufacturer, chinese Belt supplier, produce: v belts, rubber timing belts (synchronous belts), auto timing belts, double-sided tooth synchronous belts,s step less speed change belts, multi-wedge belts, motorcycle V-belts, auto V-belts and various cutting V-belts, flat belts etc rubber drive belts and its auxiliary pulley series products.. We can produce as per customer's drawing or sample. Please feel free to send us your detail enquiries. E-mail: oceanindustry@vip.163.com

Catalogue