Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

The Narrow V Belt is a specialized power transmission belt engineered to meet the high - performance demands of modern industrial and automotive applications. It represents an evolution from traditional V - belts, offering enhanced capabilities in terms of power transmission, space utilization, and durability.

The most distinctive feature of the Narrow V Belt is its cross - sectional shape. It has a trapezoidal profile, similar to standard V - belts, but with a narrower top width relative to its height. This design allows for a deeper and more secure fit within the pulley grooves. The angled sides of the trapezoid are optimized to maximize the contact area with the pulley, increasing the frictional force and thus the power - transmission capacity.

Rubber Compound: The outer layer of the Narrow V Belt is made from high - quality rubber compounds. Neoprene is a commonly used material due to its excellent resistance to abrasion, oil, and heat. In industrial settings where the belt may be exposed to harsh working conditions, neoprene ensures long - term durability. Additionally, some belts are made with specialized rubber blends that offer enhanced flexibility, allowing the belt to bend easily around small - diameter pulleys without cracking.

Reinforcement Cords: Embedded within the rubber body are high - strength reinforcement cords. These cords are typically made of materials such as polyester, nylon, or aramid. Polyester cords are cost - effective and provide good tensile strength, making them suitable for general - purpose applications. Nylon cords offer higher strength and better resistance to fatigue, while aramid cords are extremely strong and are used in applications where high - power transmission and long - term reliability are crucial. The cords are arranged in a way that they run longitudinally along the length of the belt, evenly distributing the tensile forces during operation.

Narrow V Belts are designed to transmit more power compared to standard V - belts of the same cross - sectional area. The narrower profile and deeper groove engagement enable them to handle higher torque loads. This makes them ideal for applications where space is limited, but high - power transmission is required, such as in small - sized industrial motors or high - performance automotive engines.

Their narrow design allows for a more compact installation. In machinery where space is at a premium, Narrow V Belts can be used to replace larger standard V - belts without sacrificing power - transmission capabilities. This compactness also contributes to more efficient use of space within the machine, enabling for more streamlined designs.

These belts offer high transmission efficiency. The optimized contact between the belt and pulley, along with the use of high - quality materials, reduces energy losses due to friction. As a result, Narrow V Belts can achieve transmission efficiencies of up to 98%, leading to energy savings and lower operating costs.

Despite their high - strength construction, Narrow V Belts maintain good flexibility. They can easily bend around pulleys with relatively small diameters, which is beneficial in applications where the belt needs to navigate complex pulley arrangements. This flexibility also helps in reducing stress on the belt during operation, extending its service life.

Technical Data Sheet

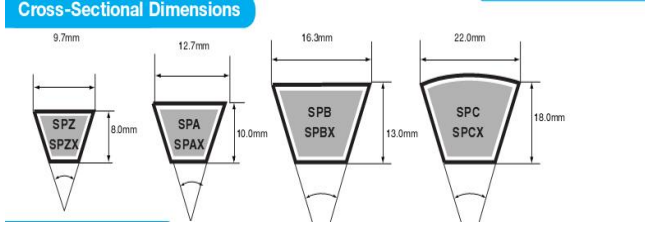

| Type | Top Width | Pitch | Height | Angle |

| SPZ/XPZ | 10 | 8 | 8 | 40 |

| SPA/XPA | 13 | 11 | 10 | 40 |

| SPB/XPB | 17 | 14 | 14 | 40 |

| APC/XPC | 22 | 19 | 18 | 40 |

| 3V/3VX(9N) | 9.5 | 8.5 | 8 | 40 |

| 5V/5VX(15N) | 16 | 14.3 | 13.5 | 40 |

| 8V/8VX(25N) | 25.4 | 23.7 | 23 | 40 |

| SPA/XPA | datum | length (mm) | ||

| 508 8 8 9 | 1270 1651 | 2032 2413 | 2794 3175 | 3556 3962 |

| 533 9 1 4 | 1295 1676 | 2057 2438 | 2819 3200 | 3581 3988 |

| 559 9 4 0 | 1321 1702 | 2083 2462 | 2845 3226 | 3607 4013 |

| 584 9 6 5 | 1346 1727 | 2108 2489 | 2870 3251 | 3632 4039 |

| 610 9 9 1 | 1372 1753 | 2134 2515 | 2896 3277 | 3658 4064 |

| 635 1016 | 1397 1778 | 2159 2540 | 2921 3302 | 3683 4089 |

| 660 1041 | 1422 1803 | 2184 2565 | 2946 3327 | 3708 4115 |

| 686 1067 | 1448 1829 | 2210 2591 | 2972 3353 | 3734 4140 |

| 710 1092 | 1473 1854 | 2235 2616 | 2997 3378 | 3759 4166 |

| 737 1118 | 1499 1880 | 2261 2642 | 3023 3404 | 3785 4191 |

| 762 1143 | 1524 1905 | 2286 2667 | 3048 3429 | 3810 4216 |

| 787 1168 | 1549 1930 | 2311 2692 | 3073 3454 | 3861 4242 |

| 813 1194 | 1575 1956 | 2337 2718 | 3099 3480 | 3886 4267 |

| 838 1219 | 1600 1981 | 2362 2743 | 3124 3505 | 3912 4293 |

| 864 1245 | 1626 2007 | 2388 2769 | 3150 3531 | 3937 4318 |

| SPZ/XPZ | datum | length (mm) | ||

| 508 660 | 813 965 | 1118 1270 | 1422 1575 | 1727 1880 |

| 533 686 | 838 991 | 1143 1295 | 1448 1600 | 1753 1905 |

| 559 710 | 864 1016 | 1167 1321 | 1473 1626 | 1778 1930 |

| 584 737 | 889 1041 | 1194 1346 | 1499 1651 | 1803 1956 |

| 610 762 | 814 1067 | 1219 1372 | 1524 1676 | 1829 1981 |

| 635 787 | 940 1092 | 1245 1397 | 1549 1702 | 1854 2007 |

| 2032 |

| 3V/3VX | outsidelength | ( inck X 10 ) |

| 250 355 | 500 710 | 1000 |

| 265 375 | 530 750 | 1060 |

| 280 400 | 560 800 | 1120 |

| 300 425 | 600 850 | 1180 |

| 315 450 | 630 900 | 1250 |

| 335 475 | 670 950 | 1320 |

| 1400 |

| 5V/5VX | outsidelength | ( inck X 10 ) |

| 500 710 | 1000 1400 | 2000 2800 |

| 530 750 | 1060 1500 | 2120 3000 |

| 560 800 | 1120 1600 | 2240 3150 |

| 600 850 | 1180 1700 | 2360 |

| 630 900 | 1250 1800 | 2500 |

| 670 950 | 1320 1900 | 2650 |

| 8V/8VX | outsidelength | ( inck X 10 ) |

| 1000 | 1400 | 2000 |

| 1060 | 1500 | 2120 |

| 1120 | 1600 | 2240 |

| 1180 | 1700 | 2360 |

| 1250 | 1800 | |

| 1320 | 1900 |

China Belt manufacturer, chinese Belt supplier, produce: v belts, rubber timing belts (synchronous belts), auto timing belts, double-sided tooth synchronous belts,s step less speed change belts, multi-wedge belts, motorcycle V-belts, auto V-belts and various cutting V-belts, flat belts etc rubber drive belts and its auxiliary pulley series products.. We can produce as per customer's drawing or sample. Please feel free to send us your detail enquiries. E-mail: oceanindustry@vip.163.com

Catalogue