Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 4 Author: Site Editor Publish Time: 2024-08-21 Origin: Site

1. Current situation investigation

A domestic Sino German cooperative company has been entangled in the material selection of reducer shafts for a long time. German personnel insist on choosing C45 high-quality carbon structural steel (Chinese steel grade is 45), while Chinese personnel insist on choosing 42CrMo alloy structural steel. Therefore, after a long discussion, in Germany, choosing C45 steel to manufacture reducer shafts can fully meet its performance, ensure sufficient service life and safety reliability, and C45 steel smelting is simple and inexpensive; In China, the domestically produced 45 # steel, although its composition and process meet the technical standards, fails to meet the requirements in terms of strength and plasticity during actual use, leading to premature failure. So the Chinese technical personnel insisted on choosing 42CrMo alloy structural steel, because the addition of metal Cr and Mo makes the comprehensive mechanical properties of 42CrMo steel much better than 45 # steel, so its performance can be fully guaranteed. The disadvantage is that the price is much higher and the cost is increased.

2. Cause analysis

International standards stipulate that the carbon (C) content of 45 # steel or C45 steel should be between 0.42% and 0.50%, the silicon (Si) content should be between 0.17% and 0.37%, the manganese (Mn) content should be between 0.5% and 0.8%, the sulfur (S) content should be less than 0.035%, and the phosphorus (P) content should be less than 0.035%, which is a qualified product. This ensures that 45 # steel has good comprehensive mechanical properties, and its performance will be even better after normalizing and quenching treatment during processing, fully guaranteeing its service life.

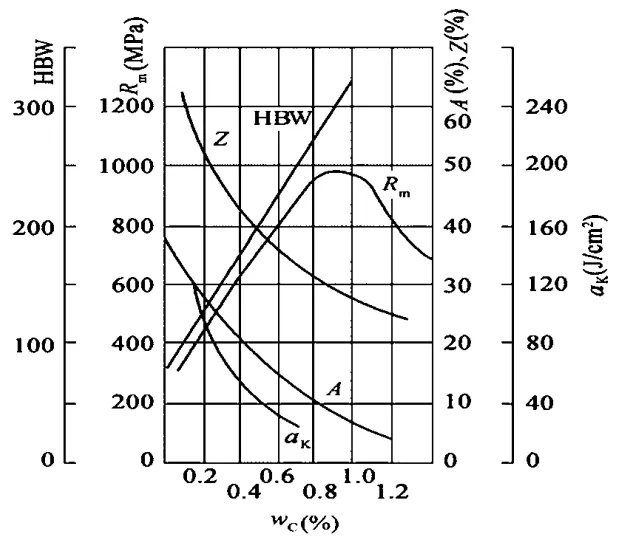

45 # steel generally meets the upper limit requirements: the carbon content can reach about 0.50%. If the silicon (Si) content in the steel is around 0.37%, the manganese (Mn) content is between 0.8% and 1.2%, and the sulfur (S) and phosphorus (P) content is less than 0.035%, then the yield strength Rs is about 392MPa, the tensile strength Rm is about 647MPa, and the hardness of hot-rolled steel is 255HBS. According to the lower limit requirements, the carbon content should reach 0.42%, the silicon (Si) content should reach 0.17%, the manganese (Mn) content should reach 0.5%, the sulfur (S) and phosphorus (P) content should be less than 0.035%, which also meets international standards and the product is qualified. However, the yield strength Rs is only 335MPa, the tensile strength Rm is 565MPa, and the hardness of hot-rolled steel is 217HBS. Although the composition of the steel produced in both specifications is within the standard requirements, both are 45 # steel (C45), the higher the carbon content, the higher the strength and hardness of the steel. Therefore, 45 # steel with a carbon content of 0.50% has higher strength and hardness than 45 # steel with a carbon content of 0.42%; The higher the content of silicon (Si) and manganese (Mn), the better it is for improving the strength and hardness of steel without reducing its plasticity and toughness; The content of sulfur and phosphorus is strictly controlled below 0.035%, which can reduce the hot and cold brittleness of steel. So, due to the difference in composition, the strength, hardness, plasticity, and toughness of the same 45 # steel vary greatly (as shown in the figure). Meanwhile, in the manufacturing process, whether the process (especially heat treatment) is properly controlled, and whether the technical level and process parameters of heat treatment meet the requirements, will also greatly affect its performance. Taking into account various factors, the service life and effectiveness of steel will vary greatly.