Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 2 Author: Site Editor Publish Time: 2024-09-10 Origin: Site

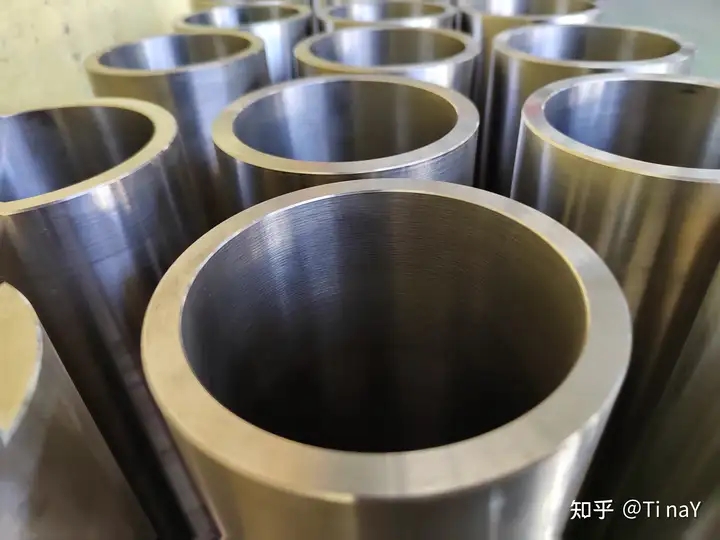

1、 The core principle of titanium tube annealing process is titanium tube annealing. As a key heat treatment process, its core lies in precisely controlling the heating temperature, time, and cooling rate to promote the transformation of the internal structure of titanium tubes, thereby optimizing their physical and chemical properties. This process aims to eliminate processing stress, refine grain structure, and significantly improve key indicators such as corrosion resistance and strength of titanium tubes.

2、 The pre-treatment stage of titanium tube annealing process implementation steps: The primary task is to ensure that the surface of the titanium tube is clean and free of dirt. By thoroughly cleaning and removing impurities such as oil stains and oxide layers, a good foundation is laid for subsequent annealing treatment. Heating treatment stage: Place the pre treated titanium tube in an annealing furnace, and set the appropriate heating temperature and duration according to the material and performance requirements of the titanium tube. Special attention should be paid to conducting this stage under a protective atmosphere to prevent the titanium tube from oxidizing at high temperatures. Cooling stage: After heating is completed, enter the cooling stage. At this stage, it is necessary to precisely control the cooling rate to induce the formation of an ideal lattice structure in the titanium tube, while avoiding the formation of poor structures such as coarse grains, which may affect the final performance. Post processing stage: After annealing is completed, the titanium tube is cleaned again and its appearance and performance are carefully inspected to ensure that there are no defects and it meets the standards.

3、 Key points of annealing process for titanium tubes: Anti oxidation measures: Considering that titanium tubes are prone to oxidation at high temperatures, the entire annealing process must be carried out in an inert gas or vacuum environment, effectively isolating air. Personalized Process: Customized annealing process parameters are required for different types of titanium tubes to ensure optimal results. Accurate temperature control and speed: Temperature and speed control during heating and cooling processes are crucial and directly affect the final performance of titanium tubes. Safety regulations: Strictly follow operating procedures and safety standards to ensure the safety of operators and equipment.

In summary, the annealing process of titanium tubes is a complex and delicate process that requires operators to have rich experience and professional knowledge. By precisely controlling each link, significant improvement in the performance of titanium tubes can be achieved, meeting the demand for high-quality titanium materials in various fields.