Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 4 Author: Site Editor Publish Time: 2025-03-05 Origin: Site

Bearing is one of the most critical moving parts in the gearbox, and its state directly affects the performance and service life of the gearbox. Bearing damage is often the main cause of gearbox failure, including roller path peeling, holder fracture, insufficient lubrication and other problems. Therefore, identifying the early damage signal of the bearing is crucial to ensure the reliable operation of the gearbox.

1. Main type of bearing damage

(1) Rolling road peeling

Roller stripping is a common form of failure in bearings, usually resulting by material fatigue or poor lubrication. When the bearing roller spoff, abnormal vibration and may cause metal debris to enter the gear box.

(2) The holder breaks

The holder guides the rolling body during the bearing operation. If the holder breaks, the rolling body may be misplaced, resulting in abnormal operation of the bearing or even stuck.

(3) Insufficient lubrication

The damage of the lubricating oil film will aggravate the friction and wear of the bearing, cause the overheating phenomenon, and accelerate the fatigue damage of the bearing. Common reasons include lubricating oil deterioration, insufficient oil quantity, or lubricating oil road blockage.

(4) Impurities contamination

Metal particles, dust and other impurities mixed into the lubricating oil will aggravate the wear of the bearing roller path and affect its service life.

2. Early warning method for bearing damage

In order to detect abnormalities before bearing damage, appropriate monitoring and diagnostic methods are crucial.

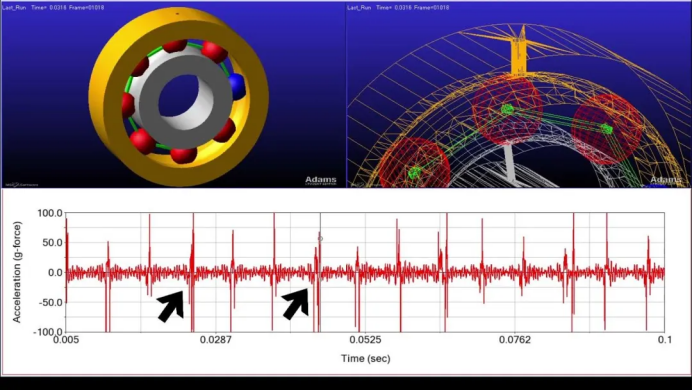

(1) Vibration monitoring

Vibration monitoring is a common means of bearing state detection. The small damage of the bearing can be identified. However, many gearboxes are not equipped with online vibration sensors, so it is impossible to obtain the operating vibration status.

(2) Temperature detection

A typical signal of bearing damage is an abnormal increase in temperature. Temperature labels can be affixed on the bearing part of the gearbox to determine whether the bearing is overheated by color change.

(3) Lubricating oil testing

It is an important method to identify the early damage of bearing to check the pollution situation of gearbox lubricating oil regularly and observe whether it contains metal wear particles or abnormal oxides.

3. Manual inspection method (without composite sensor)

In the absence of on-line vibration detection or high-precision sensors, the bearing state assessment can be performed using a manual method.

✅ Lubricating oil blackening inspection: if the lubricating oil is found as blackened, it may be a signal of excessive bearing wear.✅ Input shaft bearing inspection: manually pull and push the gearbox input shaft up and down to sense the bearing clearance and judge whether the bearing is abnormal.✅ Output shaft bearing inspection: axial push the gearbox box back and forth to assess the status of the output shaft bearing.

4. Application of bearing monitoring in operation

After the gearbox delivery, the operator usually conducts regular monitoring to ensure that the gearbox runs stably.

✅ Temperature monitoring: abnormal temperature phenomenon is found through the temperature label.

✅ Lubricating oil analysis: sample lubricating oil regularly to detect the content of particulate matter.