Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 2 Author: Site Editor Publish Time: 2025-03-20 Origin: Site

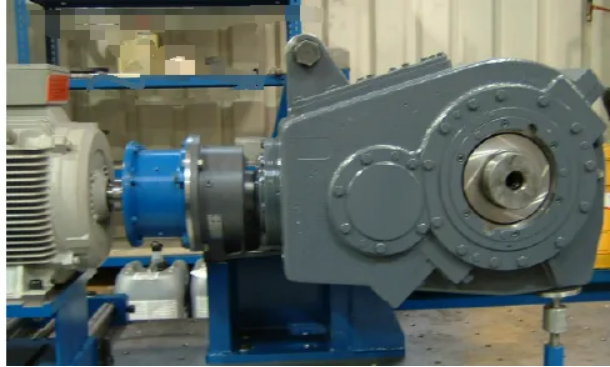

Frequency conversion drive technology is widely used in rail trains to improve energy efficiency and optimize the operation characteristics of traction system. However, the characteristics of variable frequency drive, such as speed fluctuations, frequent start and stop, and electromagnetic interference, may have an impact on the long-term stability and life of the gearbox, especially in terms of inertial impact, gear engagement stability, and lubrication system. This paper will discuss the possible failure modes when the inverter drives the gearbox, and analyze the influence on the gearbox life.

1. Characteristics of the frequency conversion drive

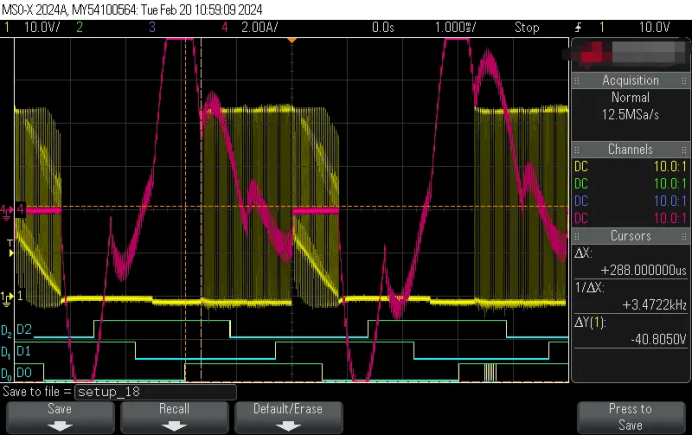

(1) The speed fluctuation of the frequency conversion motor

The frequency converter controls the motor speed by adjusting the input voltage and frequency, but under some load conditions, the speed may fluctuate, resulting in an unstable load inside the gearbox.

✅ Possible effects:

Frequent speed changes can cause uneven wear of gear engagement

When the frequency conversion control accuracy is insufficient, the gearbox may experience a sudden inertial impact

At low speed, the lubricating oil film may not form sufficiently, increasing the friction between gear and bearings

(2) Starting and braking characteristics

The start and braking of the variable frequency motor are generally relatively stable, but if the speed regulation parameters are not set properly, it may cause the gearbox to bear additional impact load during acceleration and deceleration.

✅ Possible effects:

Accelerated impact at startup may cause gear engagement to produce an instantaneous overload

Frequent braking may accelerate the fatigue damage on the gear engagement surface

The bearing may be damaged due to insufficient lubrication during the rapid start and stop process

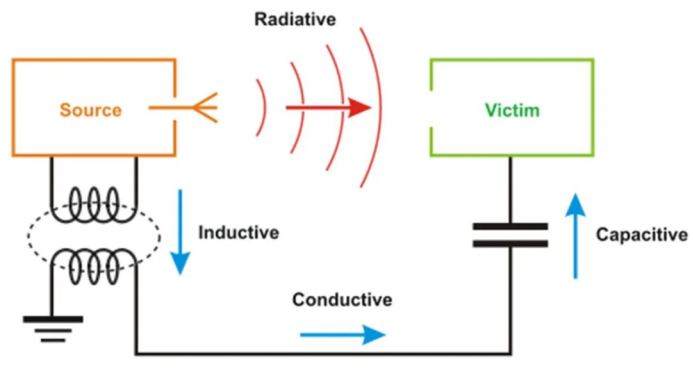

(3) The influence of electromagnetic interference on the lubrication system

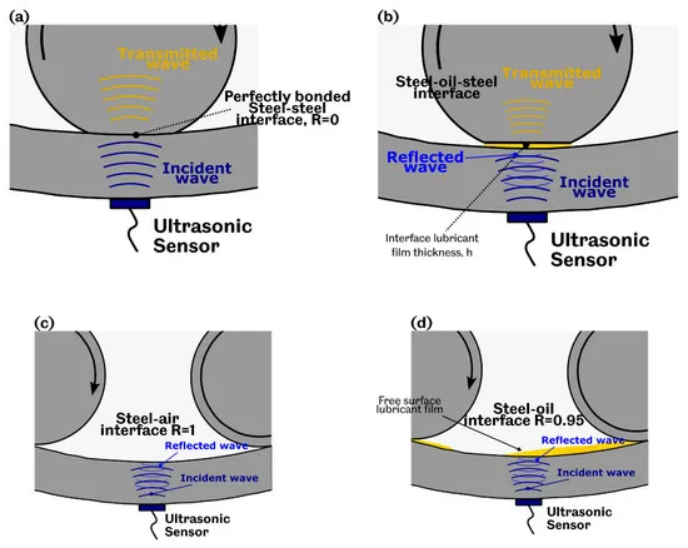

High frequency electromagnetic interference (EMI) is produced during operation, which may affect the performance of lubricating oil and produce electrical corrosion effect on bearings and gears.

✅ Possible effects:

Electromagnetic interference may lead to the accumulation of tiny particles in the lubricating oil, affecting the mobility of oil products

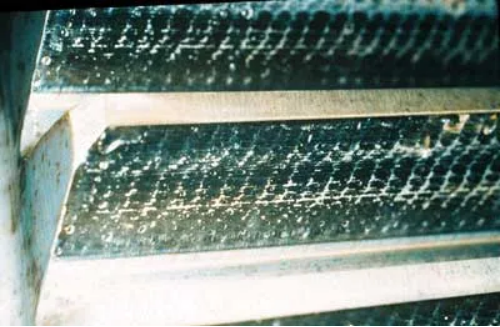

The bearing surface may form small hemp points due to electric corrosion, affecting the service life

Small current on the bearing and gear surfaces may trigger local lubricant degradation

2. Potential failure mode caused by the variable frequency drive to the gearbox

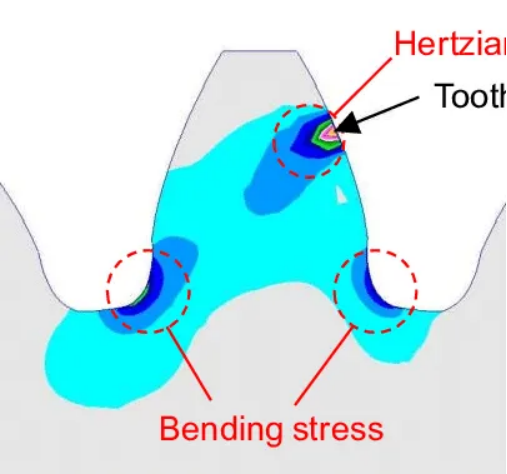

(1) Gear engagement is unstable

Because inverter motors may provide uneven torque output in different operating states, intermittent load fluctuations may occur during gear engagement, resulting in uneven force force on the gear surface.

✅ Main performance:

Early pitting or fatigue stripping of the gear and tooth surface

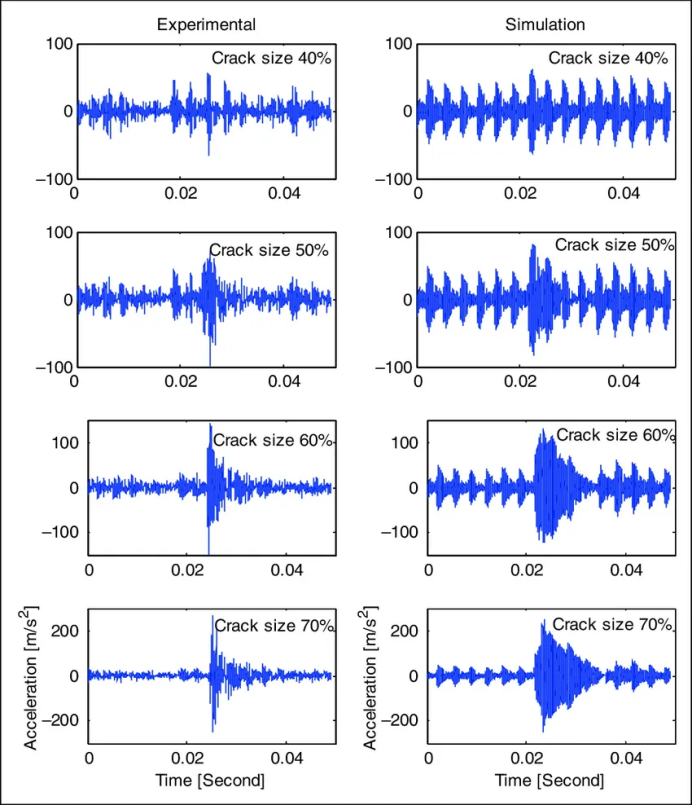

Gear box noise increases and vibration increases

The gear contact stress is concentrated, resulting in local overheating

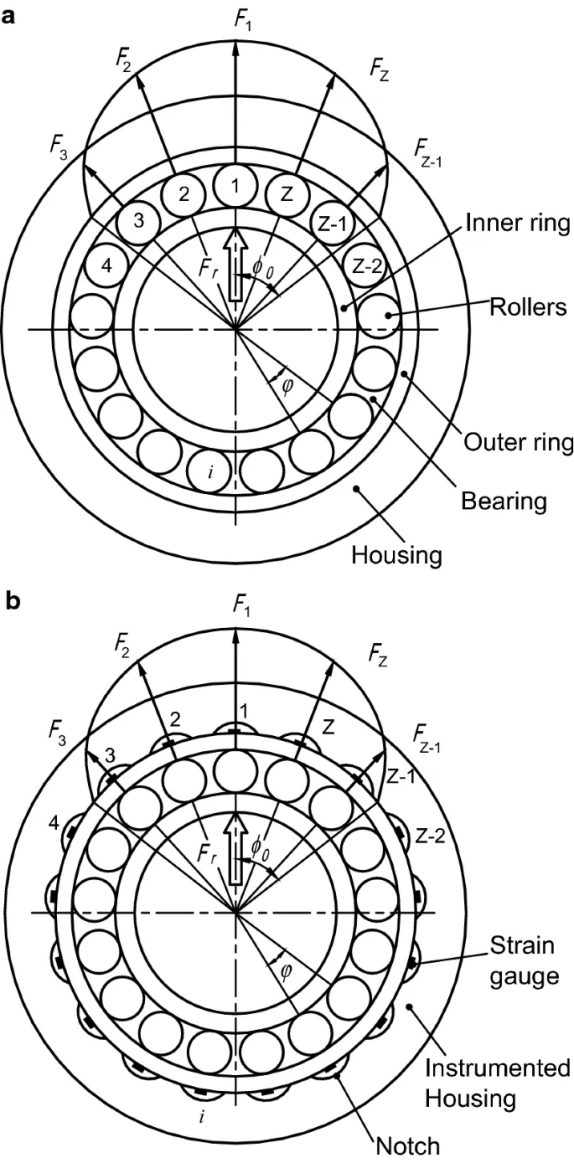

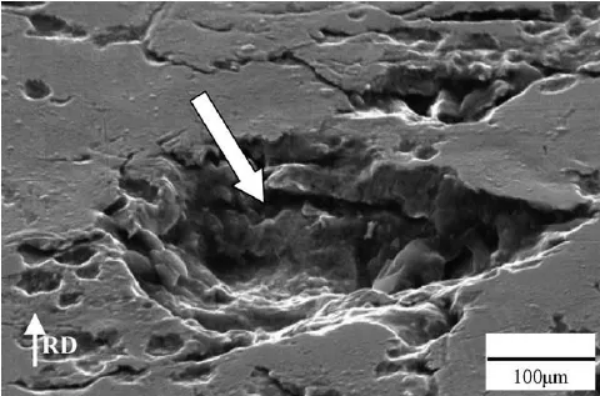

(2) Abnormal bearing load

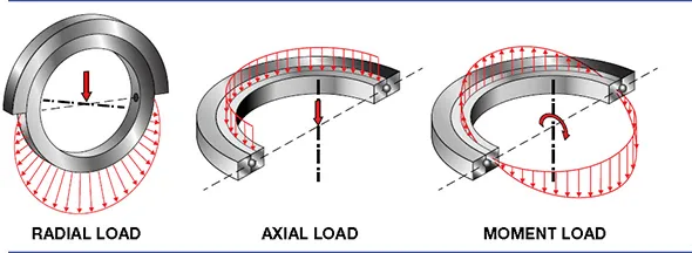

The speed variation of the frequency conversion drive may lead to the uneven radial or axial loading of the bearings in different working conditions, affecting their life.

✅ Main performance:

The bearing roller abnormal wear causes fatigue peeling

Bearing holder is broken or deformed

The ial load changes causes abnormal bearing preload force

(3) Failure of the lubrication system

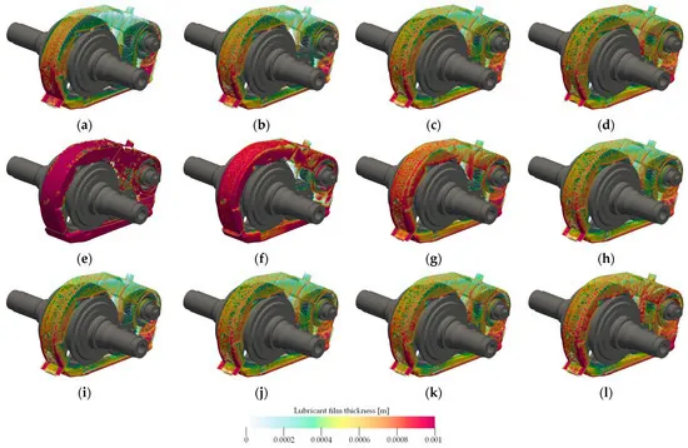

Because the frequency conversion drive may lead to the temperature fluctuation in the gearbox, the working state of the lubricating oil will also be affected, especially in low speed conditions, the lubricating oil film may not be effectively formed.

✅ Main performance:

Insufficient lubricating oil film at low speed, resulting in direct contact of the gear

Frequent start and stop lead to uneven flow of lubricating oil and oil membrane fracture

Excessive shear of lubricating oil at high speed to reduce the viscosity

3. Preventive measures and optimization suggestions

✅ Optimize the frequency conversion parameter setting: ensure that the acceleration and deceleration curves are smooth and reduce the inertial impact of the gearbox.

✅ Use electric corrosion resistant bearings: choose bearings with insulating coating or ceramic roller to reduce the impact of electric corrosion.

✅ Use high performance lubricating oil: select lubricating oil with excellent shear performance and temperature stability to adapt to different operating conditions.

✅ Regular vibration monitoring: install vibration sensor on the gearbox to monitor the state of gear and bearing and find abnormalities in advance.

✅ Improve electromagnetic shielding: reduce the impact on gearbox electromagnetic interference by optimizing the inverter grounding system and shielding measures.