Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

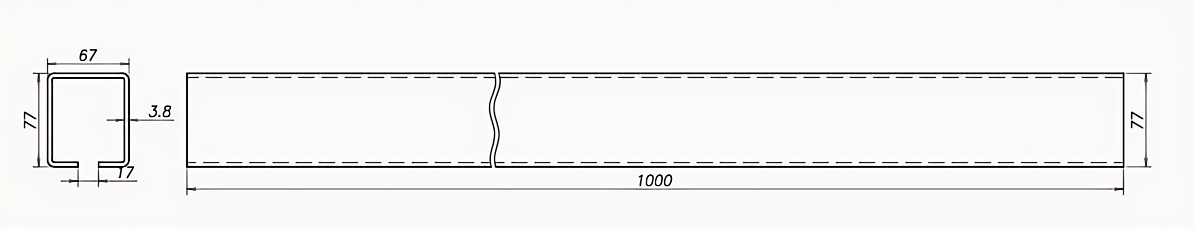

Enclosed track

Product description

The casing pipe produced by our company is a compensation device designed to absorb the elongation and shortening of the track when the conveying line passes through an area with large temperature changes. It can be used as a tensioning device and can also be used at the connection of straight tracks in the furnace. The straight track can freely expand and contract within the casing pipe, so it will not deform in an environment with thermal expansion and contraction.

Product Specification

Type | A | B | C | α |

GJ-150 | 54 | 47 | 19 | 3.5 |

GJ-200 206 | 72 | 68 | 26 | 4 |

GJ-240 250 | 80 | 80 | 25 | 4 |

GJ-300 | 100 | 100 | 32 | 5 |

Performance characteristics:

Versatility:It can be used both as a tensioning device and at the connection of straight rails in the furnace, demonstrating a wide range of applications.

Adjustability:Allows the straight rail to freely expand and contract within it, making it highly adaptable to changes in temperature. This ensures that the connected components can function properly even in environments with significant thermal fluctuations.

Stability:By providing a stable enclosure for the straight rail, it helps prevent deformation and maintains the integrity of the overall structure. This leads to increased stability and reliability of the equipment in which it is used.

Durability:Made of materials that are likely to be resistant to heat, corrosion, and wear, ensuring a long service life even in harsh environments.

Application

As a tensioning device

The casing serves as a tensioning device, playing an important role in adjusting the tension of specific components to ensure stable operation.

For furnace straight rail connections

It can also be used at the connection of straight rails in the furnace, showing unique advantages.

Straight rail can freely expand and contract

The straight rail can freely move inside the casing, adapting to thermal expansion and contraction.

Avoid deformation and ensure stability

This enables the straight rail not to deform in a changing temperature environment, enhancing stability and reliability, and reducing maintenance costs.

Structural parameter

Material selection: The casing is usually made of materials resistant to high temperatures, corrosion, and with some elasticity to ensure no deformation or damage in the furnace's high-temperature environment and adapt to thermal expansion and contraction.

Connection structure: For furnace straight rail connections, the casing ends need suitable connection structures for firm attachment to the straight rail. Connection methods like threaded, flange, or welding depend on the application scenario and installation requirements.

Sealing performance: To prevent furnace dust and hot air from entering and affecting the straight rail's telescopic performance, the casing needs good sealing. A sealing gasket or special sealing structure at the connection can ensure isolation from the external environment.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: generally 15 workdays.

2.Production Lead-times: 30-60 workdays after getting your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

We'll show you the photos of the products and packages before you pay the balance.

Q4: What is your advantages?

1. Manufacturer,the most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

4. Rich stock and quick delivery.

Q5. If you can’t find the product on our website,what do you next?

Please send us inquiry with product pictures and drawings by email or other ways and we'll check.