Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

Compared with chain and belt drives, the Engraving Machine Gear Rack has the following advantages:

1.It can achieve the conversion between rotary motion and linear reciprocating motion;

2.Accurate instantaneous transmission ratio;

3.High transmission efficiency.

4.Long life span,etc.

Most of Ocean Engraving Machine Gear Rack are exported to Europe since 2005. Most of Ocean OEM customers send drawings and Ocean produce as per their drawings, if you do not have drawing, Ocean can also produce as per your sample.

parameter

| Manufacturing Description: |

| Precision Grade: (JIS Grade 6) DIN 10e27 |

| Material: S45C |

| Type: Straight Rack |

| Treatment ofTeeth: Milled |

| Hardness: High Frequency,HRC43~45 degree. |

| Sides Ground: not included. |

| Pressure Angle: 20 degree. |

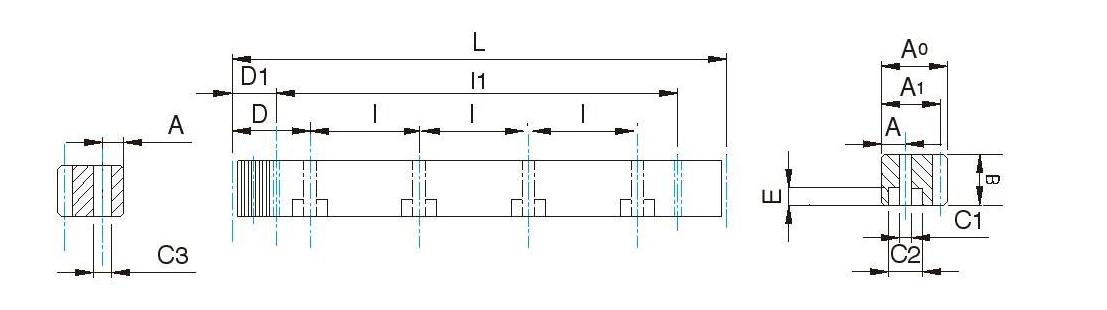

| Code | Module | L | Teeth No. | B | A0 | A1 | D | I | Hole No. | A | C1 | C2 | E | D1 | I1 | C3 | Pitch Eror /300mm | |

| 010 | 05 | 1 | 499.51 | 159 | 15 | 15 | 14 | 一 | 一 | 一 | 一 | 一 | 一 | 一 | 一 | 一 | 一 | 0.080 |

| 15 | 05 | 1.5 | 499.51 | 106 | 17 | 17 | 15.5 | 62.44 | 124.88 | 4 | 8 | 6 | 9.5 | 7 | 29 | 441.5 | 5.7 | 0.082 |

| 15 | 10 | 1.5 | 999.03 | 212 | 17 | 17 | 15.5 | 62.44 | 124.88 | 8 | 8 | 6 | 9.5 | 7 | 29 | 941.0 | 5.7 | 0.082 |

| 020 | 05 | 2 | 502.65 | 80 | 24 | 24 | 22 | 62.83 | 125.66 | 4 | 8 | 7 | 11 | 7 | 31.3 | 440.1 | 5.7 | 0.086 |

| 020 | 10 | 2 | 1005.31 | 160 | 24 | 24 | 22 | 62.83 | 125.66 | 8 | 8 | 7 | 11 | 7 | 31.3 | 942.7 | 5.7 | 0.086 |

| 30 | 05 | 3 | 508.94 | 54 | 29 | 29 | 26 | 63.62 | 127.23 | 4 | 9 | 10 | 15 | 9 | 34.4 | 440.1 | 7.7 | 0.091 |

| 30 | 10 | 3 | 1017.88 | 108 | 29 | 29 | 26 | 63.62 | 127.23 | 8 | 9 | 10 | 15 | 9 | 34.4 | 949.1 | 7.7 | 0.091 |

| 40 | 05 | 4 | 502.65 | 40 | 39 | 39 | 35 | 62.83 | 125.66 | 4 | 12 | 10 | 15 | 9 | 37.5 | 427.7 | 7.7 | 0.095 |

| 040 | 10 | 4 | 1005.31 | 80 | 39 | 39 | 35 | 62.83 | 125.66 | 8 | 12 | 10 | 15 | 9 | 37.5 | 930.3 | 7.7 | 0.095 |

| 050 | 05 | 5 | 502.65 | 32 | 49 | 39 | 34 | 62.83 | 125.66 | 4 | 12 | 14 | 20 | 13 | 30.1 | 442.4 | 11.7 | 0.098 |

| 50 | 10 | 5 | 1005.31 | 64 | 49 | 39 | 34 | 62.83 | 125.66 | 8 | 12 | 14 | 20 | 13 | 30.1 | 945 | 11.7 | 0.098 |

| 060 | 05 | 6 | 508.94 | 27 | 59 | 49 | 43 | 63.62 | 127.23 | 4 | 16 | 18 | 26 | 17 | 31.4 | 446.1 | 15.7 | 0.100 |

| 60 | 10 | 6 | 1017 88 | 54 | 59 | 49 | 43 | 63.62 | 127.23 | 8 | 16 | 18 | 26 | 17 | 31.4 | 955 | 15.7 | 0.100 |

| 080 | 05 | 8 | 502.65 | 20 | 79 | 79 | 71 | 62.83 | 125.66 | 4 | 25 | 22 | 33 | 21 | 26.6 | 449.45 | 19.7 | 0.105 |

| 080 | 10 | 8 | 1005.31 | 40 | 79 | 79 | 71 | 62.83 | 125.66 | 8 | 25 | 22 | 33 | 21 | 26.6 | 952 | 19.7 | 0.105 |

| 100 | 10 | 10 | 1005.31 | 32 | 99 | 99 | 89 | 62.83 | 125.66 | 8 | 32 | 33 | 48 | 32 | 125.7 | 753.96 | 19.7 | 0.110 |

| Manufacturing Description: |

| Precision Grade:(lS Grade6)DIN 10e27 |

| Material: S45C |

| Type: Helical Rack |

| Treatment of Teeth: Milled |

| Hardness: High Freguency.HRC43~45 degree. |

| Sides Ground: not included. |

| Right Hand Angle: l9° 31'42” |

| Pressure Angle: 20 degree. |

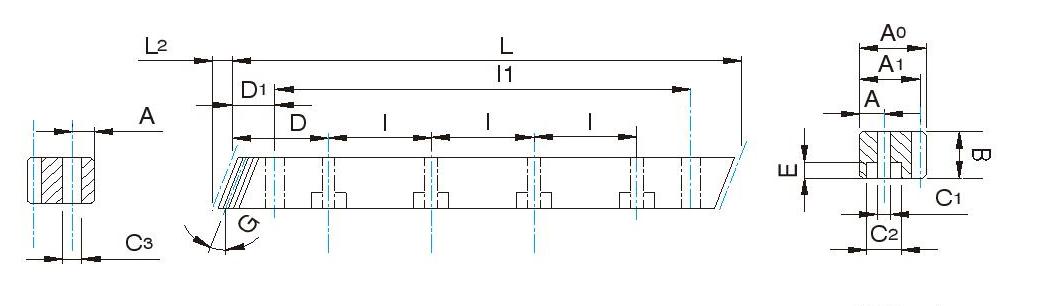

| Code | Module | L | L2 | Teeth No | B | A0 | A1 | D | I | Hole No. | A | C1 | C2 | E | D1 | I1 | C3 | Pitch Eror /300mm | |

| 010 | 05 | 1 | 500.00 | 3.14 | 150 | 15 | 15 | 14 | - | - | - | - | - | - | - | - | - | - | 0.080 |

| 015 | 05 | 1.5 | 500.00 | 6.7 | 100 | 17 | 17 | 15.5 | 62.5 | 125 | 4 | 8 | 6 | 9.5 | 7 | 31.7 | 436.6 | 5.7 | 0.083 |

| 015 | 10 | 1.5 | 1000.00 | 6.7 | 200 | 17 | 17 | 15.5 | 62.6 | 126 | 8 | 8 | 6 | 9.5 | 7 | 31.7 | 936.6 | 5.7 | 0.083 |

| 020 | 05 | 2 | 500.00 | 8.5 | 75 | 24 | 24 | 22 | 62.5 | 125 | 4 | 8 | 7 | 11 | 7 | 31.7 | 436.6 | 5.7 | 0.086 |

| 020 | 10 | 2 | 1000.00 | 8.5 | 150 | 24 | 24 | 22 | 62.5 | 125 | 8 | 8 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 | 0.086 |

| 030 | 05 | 3 | 500.00 | 10.3 | 50 | 29 | 29 | 26 | 62.5 | 125 | 4 | 9 | 10 | 15 | 9 | 35.0 | 430.0 | 7.7 | 0.091 |

| 030 | 10 | 3 | 1000.00 | 10.3 | 100 | 29 | 29 | 26 | 62.5 | 125 | 8 | 9 | 10 | 15 | 9 | 35.0 | 930.0 | 7.7 | 0.091 |

| 040 | 05 | 4 | 506.67 | 13.8 | 38 | 39 | 39 | 35 | 62.5 | 125 | 4 | 12 | 10 | 15 | 9 | 33.3 | 433.0 | 7.7 | 0.095 |

| 040 | 10 | 4 | 1000.00 | 13.8 | 75 | 39 | 39 | 35 | 62.5 | 125 | 8 | 12 | 10 | 15 | 9 | 33.3 | 933.4 | 7.7 | 0.095 |

| 050 | 05 | 5 | 500.00 | 17.4 | 30 | 49 | 39 | 34 | 62.5 | 125 | 4 | 12 | 14 | 20 | 13 | 37.5 | 425.0 | 11.7 | 0.098 |

| 050 | 10 | 5 | 1000.00 | 17.4 | 60 | 49 | 39 | 34 | 62.5 | 125 | 8 | 12 | 14 | 20 | 13 | 37.5 | 925.0 | 11.7 | 0.098 |

| 060 | 05 | 6 | 500.00 | 20.9 | 25 | 59 | 49 | 43 | 62.5 | 125 | 4 | 16 | 18 | 26 | 17 | 37.5 | 425.0 | 15.7 | 0.100 |

| 060 | 10 | 6 | 1000.00 | 20.9 | 50 | 59 | 49 | 43 | 62.5 | 125 | 8 | 16 | 18 | 26 | 17 | 37.5 | 925.0 | 15.7 | 0.100 |

| 080 | 05 | 8 | 480.00 | 28.0 | 18 | 79 | 79 | 71 | 60.0 | 120 | 4 | 25 | 22 | 33 | 21 | 120 | 240.0 | 19.7 | 0.105 |

| 080 | 10 | 8 | 960.00 | 28.0 | 36 | 79 | 79 | 71 | 60.0 | 120 | 8 | 25 | 22 | 33 | 21 | 120 | 720.0 | 19.7 | 0.105 |

| 100 | 10 | 10 | 1000.00 | 35.11 | 30 | 99 | 99 | 89 | 62.5 | 125 | 8 | 32 | 33 | 48 | 32 | 125 | 750.0 | 19.7 | 0.110 |

| 120 | 10 | 12 | 1000.00 | 42. 56 | 25 | 120 | 120 | 108 | 40 | 125 | 8 | 40 | 39 | 58 | 38 | 102.5 | 750.0 | 19.7 | 0.111 |

| Manufacturing Descrpton: |

| Precision Grade: ( JS Grade 4) DIN 8e25 |

| Material: (S45C Medium Carbon Steel)C45 |

| Type: Straight Rack |

| Treatment of Teeth: Milled |

| Hardness: No Heat treatment. |

| Pressure Angle: 20 degree. |

| Material can be used 42CrM04 |

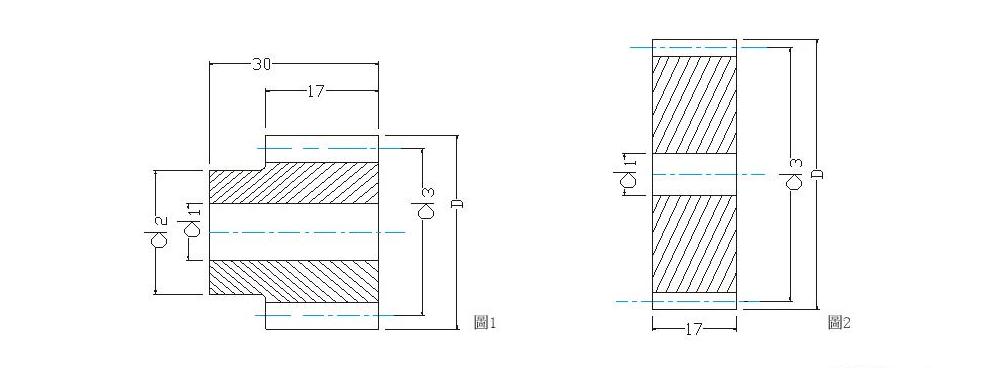

| Code | chart | Teeth No. | d1 | d2 | d3 | D | w1 | w2 | k | h | |

| 15 | 12 | 1 | 12 | 6 | 14 | 18.0 | 21.0 | ||||

| 15 | 13 | 1 | 13 | 6 | 14 | 19.5 | 22.5 | ||||

| 15 | 14 | 1 | 14 | 6 | 16 | 21.0 | 24.0 | ||||

| 15 | 15 | 1 | 15 | 6 | 18 | 22.5 | 25.5 | ||||

| 15 | 16 | 1 | 16 | 6 | 18 | 24.0 | 27.0 | ||||

| 15 | 17 | 1 | 17 | 9 | 20 | 25.5 | 28.5 | ||||

| 15 | 18 | 1 | 18 | 9 | 20 | 27.0 | 30.0 | ||||

| 15 | 19 | 1 | 19 | 9 | 20 | 28.5 | 31.5 | ||||

| 15 | 20 | 1 | 20 | 9 | 25 | 30.0 | 33.0 | ||||

| 15 | 21 | 1 | 21 | 9 | 25 | 31.5 | 34.5 | ||||

| 15 | 22 | 1 | 22 | 9 | 25 | 33.0 | 36.0 | ||||

| 15 | 23 | 1 | 23 | 9 | 25 | 34.5 | 37.5 | ||||

| 15 | 24 | 1 | 24 | 9 | 25 | 36.0 | 39.0 | ||||

| 15 | 25 | 1 | 25 | 9 | 25 | 37.5 | 40.5 | ||||

| 15 | 30 | 1 | 30 | 9 | 30 | 45.0 | 48.0 | ||||

| 15 | 35 | 1 | 35 | 9 | 40 | 52.5 | 55.5 | ||||

| 15 | 38 | 1 | 38 | 9 | 40 | 57.0 | 60.0 | ||||

| 15 | 40 | 1 | 40 | 9 | 40 | 60.0 | 63.0 | ||||

| 15 | 45 | 1 | 45 | 12 | 50 | 67.5 | 70.5 | ||||

| 15 | 48 | 1 | 48 | 12 | 50 | 72.0 | 75.5 | ||||

| 15 | 50 | 1 | 50 | 12 | 50 | 75.0 | 78.0 | ||||

| 15 | 57 | 1 | 57 | 12 | 60 | 85.5 | 88.5 | ||||

| 15 | 60 | 1 | 60 | 12 | 60 | 90.0 | 93.5 | ||||

| 15 | 76 | 2 | 76 | 16 | 114.0 | 117.0 | |||||

| 15 | 80 | 2 | 80 | 16 | 120.0 | 123.0 | |||||

| 15 | 95 | 2 | 95 | 20 | 142.5 | 145.5 | |||||