Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-04-24 Origin: Site

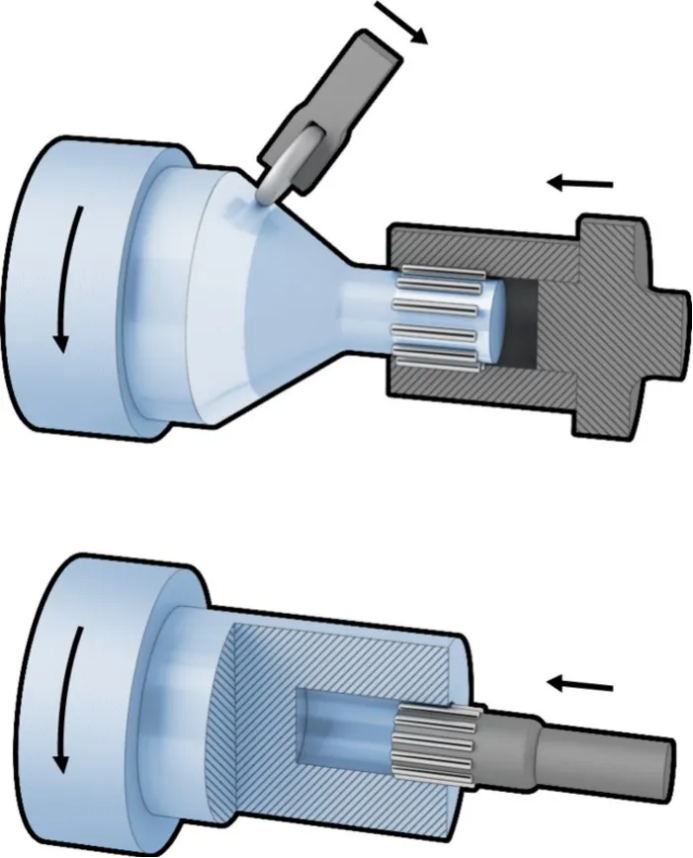

In high-load, high-intensity operating conditions, the surface strength and fatigue resistance of gear components are crucial to the reliability of the entire system. In addition to conventional heat treatment methods, gear roll strengthening (Roller Burnishing /Cold Rolling), as a non-cutting, material-removal-free plastic forming process, is widely applied in areas such as rail transit, automotive transmissions, and construction machinery.

This paper systematically interprets the principle, process path, performance improvement mechanism and typical application of gear rolling strengthening in rail transit field.

1. Improve surface hardness

After rolling, the microstructure of tooth surface is hardened, and the hardness is increased by 10~30%. The effect is particularly obvious for medium carbon alloy steel or low alloy steel.

2. Introduce residual compressive stress

The compressive stress can effectively inhibit the crack propagation and is the key to improve the contact fatigue life and bending fatigue life.

3. Improve surface quality

After rolling, the roughness of the tooth surface is reduced, and the typical value can be reduced from Ra1.6μm to Ra0.4μm, and the tooth surface is more stable.

4. Correct minor processing errors

It has a certain adaptive trimming function for heat treatment deformation and small root error.

Scope of application of rolling process

Key parameters of gear rolling

1. Roller pressure (F)

The pressure applied to the tooth surface should be greater than the yield strength of the material, usually taken as 200~800 MPa, depending on the material and tooth surface shape.

2. Feed speed and speed

The feed speed of the roller should be controlled at 1~3 mm/s;

The speed of the gear should not be too fast, usually less than 200 rpm, to prevent heat rise and surface overpressure.

3. Roller material and profile

Common materials: cemented carbide, carburized steel;

The roller profile must be accurately matched with the root fillet area to avoid "stress concentration".

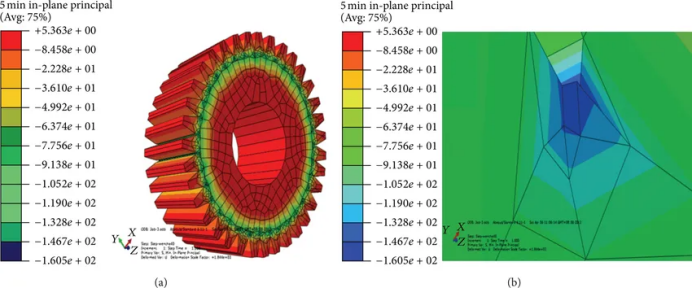

The strengthening mechanism of gear rolling

The hardened layer formed by rolling is about 0.2~0.5 mm deep, and the microstructure in this area is compacted, with dense slip lines and residual compressive stress as shown in the figure:

The reinforced gear has the following characteristics:

Contact fatigue life increased by 30%~80%;

The bending fatigue strength is increased by 20%~50%;

The noise declaration is significantly reduced, and the engagement stability is enhanced;

High temperature oxidation resistance is improved and lubricating oil retention time is extended.

Application of rolling strengthening in rail transit gears

In the gear box of rail transit, because it is in a state of high speed, large torque and impact load for a long time, although the traditional heat treatment can meet the basic strength requirements, the fatigue damage at the root of the tooth is still the main cause of failure.

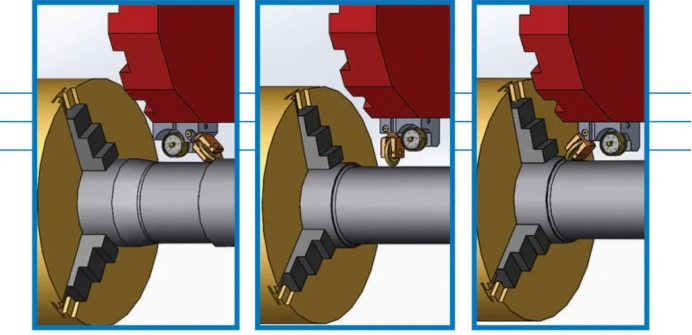

Typical practices:

Rolling and strengthening the root of small gear after carburizing and quenching;

The matching shaping strategy (tooth top chamfer + tooth root rolling) forms a high durability gear pair;

It is used in locomotive gearbox and high-speed train power system.

Practical suggestions for the process

✔ corollary equipment:

Special tooth root rolling machine (can be numerically controlled to adjust the roller path);

It has a high rigidity rolling spindle and an adjustable pressure module.

✔ detection mode:

Surface residual compressive stress detection: X-ray diffraction;

Surface hardness: HRc test;

Gear meshing noise test;

Fatigue strength test (bending/contact).Gear rolling strengthening technology, as an important means to enhance the surface properties of gears, has become one of the core processes in high-reliability fields such as rail transit, aerospace, and wind power. By introducing residual compressive stress and improving surface finish and hardness, this technology effectively delays gear fatigue failure, serving as another safety barrier beyond heat treatment.