Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 1 Author: Site Editor Publish Time: 2025-04-29 Origin: Site

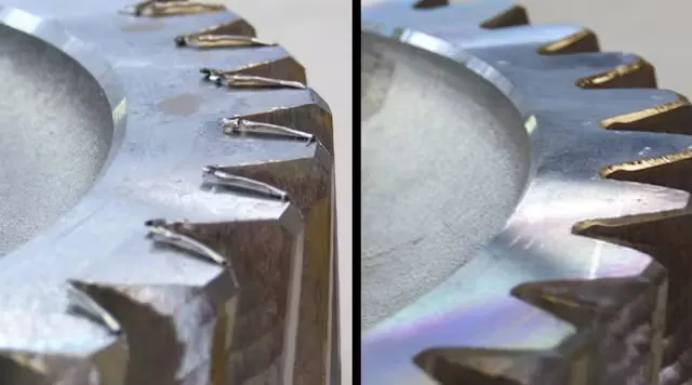

In the gear manufacturing process, whether it is rolling, broaching, or grinding operations, there are often tiny burrs and sharp edges on the tooth surfaces and roots of gears. If these minor defects are not promptly removed, they not only affect the meshing accuracy of the gears but can also become stress concentration points, leading to premature tooth surface spalling, cracks, or even tooth breakage. Therefore, deburring and edge strengthening of gears are crucial steps to ensure gear quality and reliable performance.

This paper systematically analyzes the commonly used deburring and edge strengthening process methods in gear manufacturing, as well as related standards and technical points.

The generation and harm of gear burr

After gear cutting, heat treatment or grinding, due to local plastic deformation of metal or processing residue, it is easy to form small burrs and sharp edges in the tip, root and side of the gear. These burrs not only affect assembly, but also may lead to:

Engagement noise increases

The lubricating film is destroyed and the bonding is induced

Stress concentration reduces the fatigue life of gears

Subsequent heat treatment and painting process are blocked

Gear deburring and strengthening process method

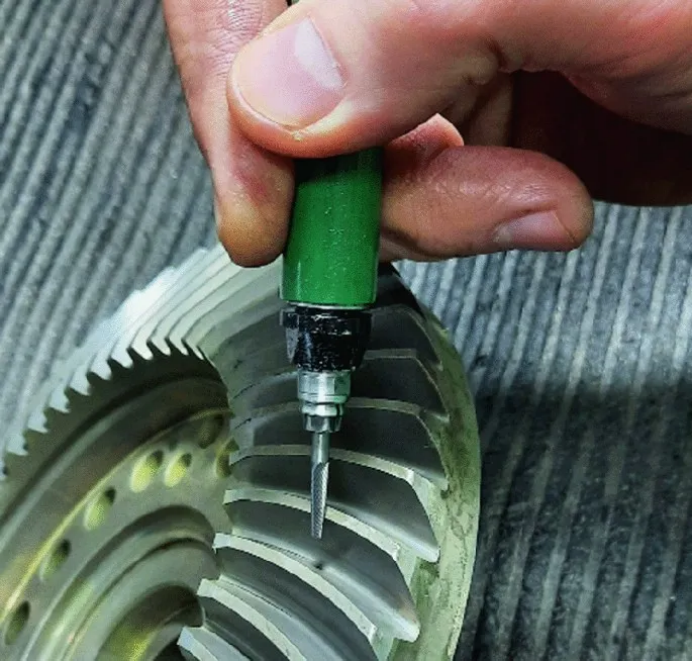

1. Mechanical deburring (manual + automatic)

Method: The tooth tip and root are locally ground by pneumatic grinding machine, manual file and burr remover.

Features: suitable for small batch, multi-variety production, high flexibility.

Disadvantages: poor artificial consistency, difficult to accurately control the amount of removal.

Standard reference: DIN 3960 Terms of Tolerances for Gear Manufacturing requires that there is no burr at the root and tip of the tooth and the transition is smooth.

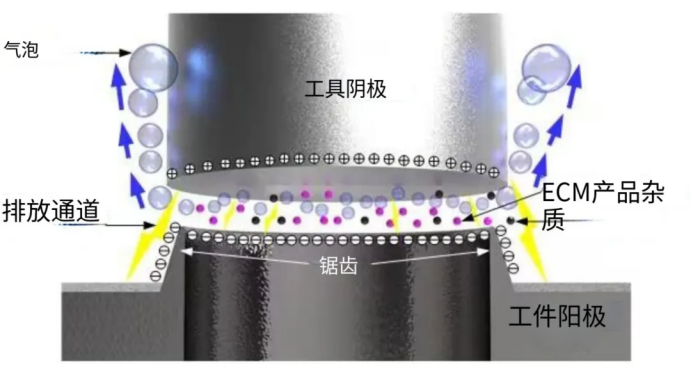

Electrode removal (Electrochemical Deburring, ECD)

Method: In a specific electrolyte, the gear is used as anode, and local high density discharge corrosion is used to remove burrs.

Features: suitable for removing the root of teeth, cross holes and other parts that are difficult to be mechanically ground, high efficiency and does not destroy the base material.

Disadvantages: high equipment cost, strict process parameter control requirements.

Standard control: surface roughness variation should be controlled within Ra≤0.8μm.

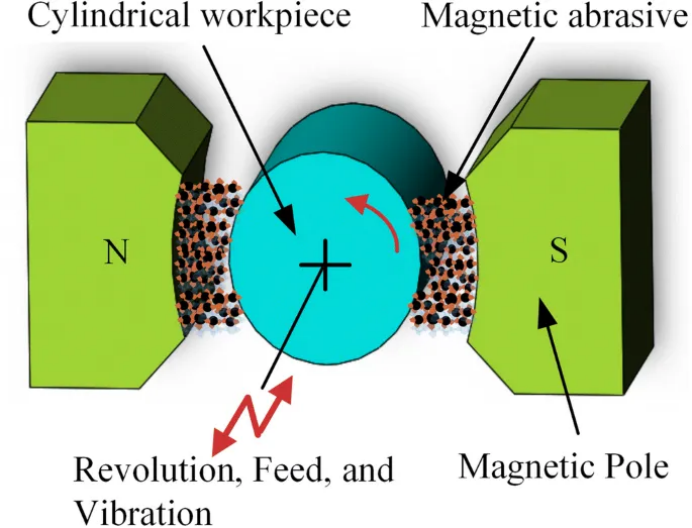

Magnetic grinding to remove burrs (Magnetic Abrasive Finishing, MAF)

Method: The gear is mixed with magnetic abrasive and ground with burrs under the action of magnetic field.

Features: can realize deburring, surface strengthening and trace polishing at the same time, suitable for large batch of small modulus gears.

Shortcomings: The process equipment requires expertise and the initial commissioning time is long.

Quality standard: no visible burr on the surface of the gear, smooth tooth tip and natural transition of the root.

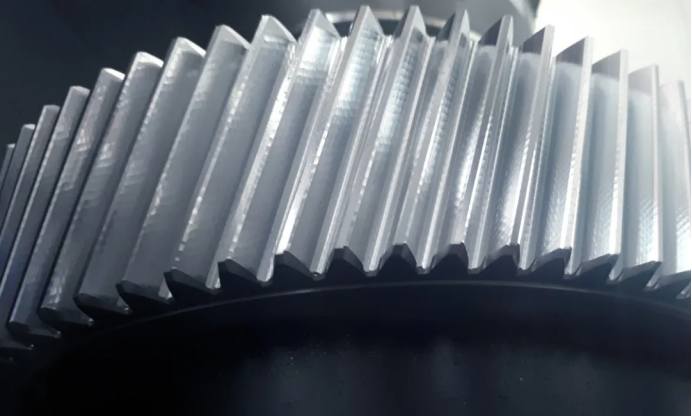

The importance of edge strengthening treatment

Gears that have been deburred usually need to be rounded or chamfered at the edge to reduce stress concentration under high frequency impact loads. Edge strengthening can significantly improve:

Cusp bending fatigue strength (10%-30% increase)

Gear durability and meshing stability

The ability to form and maintain lubricating oil film

Common standards stipulate:

| project | project |

| Standards of conduct | Standards of conduct |

| The radius of the top circle is r | The radius of the top circle is r |

| 0.1mm~0.3mm (depending on the modulus) | 0.1mm~0.3mm (depending on the modulus) |

Standard reference: ISO 1328 Tapered cylindrical gear tolerance, DIN 3967 Gear groove and fillet standard

Deburring and edge strengthening of gears, although they are details in the manufacturing process, play a crucial role in the meshing performance, service life and safety of gears. By reasonably selecting deburring methods, standardizing operation standards and strictly inspecting, the overall quality of gears can be effectively improved and early failure avoided.

In rail transit, wind power, aviation and other fields, the control of gear detail quality is particularly strict. The rigorous implementation of each process in the manufacturing process will eventually be deposited into the reliability and safety of gear operation.