Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 4 Author: Site Editor Publish Time: 2025-04-21 Origin: Site

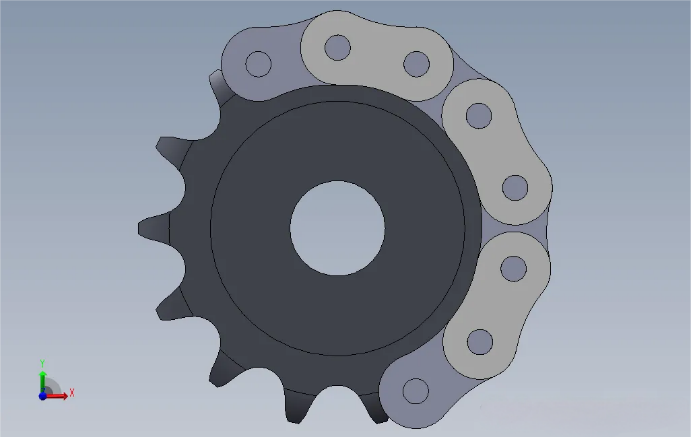

Chain drive is a mechanical transmission method that uses chains to transfer power from one rotating part (the driving sprocket) to another rotating part (the driven sprocket). The driving sprocket engages with the chain, causing it to move. The chain then engages with the driven sprocket, enabling the driven sprocket to rotate at a specific gear ratio. The gear ratio is equal to the number of teeth on the driving sprocket divided by the number of teeth on the driven sprocket. For example, if the driving sprocket has 20 teeth and the driven sprocket has 10 teeth, the gear ratio is 2:1, meaning that for every one full turn of the driving sprocket, the driven sprocket makes two turns. Generally, the efficiency of chain drives ranges from 92% to 98%, due to the relatively low rolling friction (in roller chains) or meshing friction (in spur chains) between the chain and the sprocket, which effectively transmits power.

How to judge the tightness of the chain? Observation method

◆ Chain Sag Observation: For chains placed horizontally or nearly horizontally, this is a simple and intuitive method. Stand on one side of the chain, align your line of sight with it, and observe the sag between the two sprockets. If the arc formed by the chain's sag is relatively gentle and within 1% to 3% (generally) of the center distance, it usually indicates that the chain is appropriately tensioned. For example, if the center distance between the two sprockets is 500mm, a sag of 5 to 15mm is considered normal.

◆ Operation Observation: Initially observe the tension of the chain when the equipment is stationary. Then start the equipment and run the chain at its normal operating speed. Observe the engagement of the chain on the sprocket. If the chain can rotate smoothly around the sprocket without noticeable up-and-down jumping, shaking, or signs of disengagement from the sprocket, this indicates that the chain's tension may be within a reasonable range. However, this method can only provide an initial assessment and may not detect minor non-compliance issues.

metry

◆ Chain Sag Measurement: Use professional measuring tools such as a caliper or straightedge to measure the sag of the chain. Place the caliper or straightedge vertically at the lowest point of the chain and measure the distance from the bottom of the straightedge to the lowest point of the chain. To improve measurement accuracy, take multiple measurements at different positions on the chain and then average them. Compare these measurements with the specified sag range to determine if the chain is properly tensioned.

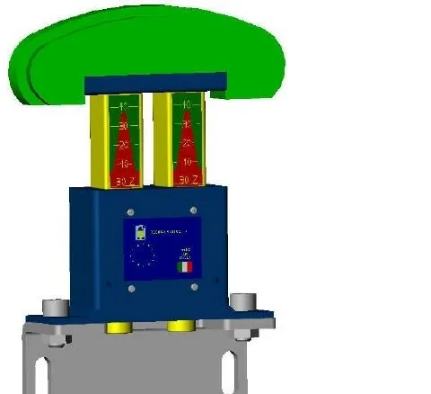

◆ Tension Measurement: Use a tension meter to accurately measure the tension of the chain. According to the specifications and application scenarios of the chain, place the sensor of the tension meter in contact with the chain and read the tension value according to the operating instructions of the tension meter. For equipment with tension standards, such as certain high-precision automated devices, this method can accurately determine whether the chain's tightness meets the standard. Different types of tension meters are suitable for different chain specifications and tension ranges; choose the appropriate tension meter when using it.

antitheses

◆ Comparison with the newly installed state: If the equipment's chain is newly installed and has been adjusted to the appropriate tension during installation, this can serve as a standard for comparison. After the equipment has been running for some time, observe the condition of the chain again. If you notice a significant increase in sag or if the chain becomes much looser than when it was first installed, it may be necessary to check whether the chain meets the tension standards and consider whether adjustments are needed.

◆ Comparison with Similar Equipment: When there are multiple identical or similar devices, the chain condition of the inspected equipment can be compared with that of normally operating similar equipment. Observe aspects such as the sag of the chain and its stability during operation. If the chain condition of the inspected equipment differs significantly from that of the normal equipment, for example, if the sag is noticeably greater or if there is abnormal vibration during operation, further inspection is needed to check whether the tension meets the standard.

two

How to adjust the chain tightness

0 Adjust the intermediate distance method

◆ Structure that can adjust the spacing of the chain wheel

For some sprockets with adjustable mounting bases, this is a common method. Many equipment sprocket mounting bases are designed with long holes or use slider structures. By loosening the bolts that fix the sprocket and moving the sprocket, the center distance between two sprockets can be changed. For example, in small conveying equipment, when the chain is found to be too loose, the bolts on the sprocket mounting base are loosened, and the sprocket is moved away from the other sprocket along the long hole or slider track, increasing the center distance and thus tightening the chain. During the adjustment process, the method for judging chain tension (such as observing sag or measuring tension) should be used to check the chain's tightness in real time until the appropriate tension is achieved, then the bolts are tightened.

◆ Increase or decrease the shim adjustment

In some equipment, the installation position of the sprocket is controlled by the thickness of the washer to control the center distance. If the chain is too loose, the thickness of the washer can be reduced appropriately; if the chain is too tight, the thickness of the washer can be increased.

Take the chain drive of a motorcycle as an example. There are usually shims at the mounting points of the sprocket and the engine or rear wheel. When it is necessary to adjust the tightness of the chain, maintenance personnel can increase or decrease the number or thickness of the shims according to the actual situation, and then check the operation of the chain after adjustment.

Use the tensioning device method

◆ Spring tensioner

Spring tensioners are a relatively common device. They typically consist of a tension wheel with a spring, which is mounted on the slack side of the chain. When the chain is slack, the spring force applies pressure to the tension wheel, thereby tightening the chain.

In some automated production line chain conveyors, spring tensioners can automatically compensate for the elongation of the chain after long-term operation. By adjusting the preload of the spring, the pressure exerted by the tensioning wheel on the chain can be controlled, thus regulating the tightness of the chain. Generally, the preload of the spring can be changed by rotating adjustment nuts or similar methods to ensure that the tensioning wheel's pull on the chain meets the required standards.

◆ Hydraulic or pneumatic tensioning device

In large, heavy-duty machinery or some high-precision equipment, hydraulic or pneumatic tensioning devices may be used. These devices can provide more accurate and stable tensioning force.

Taking the large chain scraper conveyor in mining equipment as an example, the hydraulic tensioning device can precisely adjust the tension force based on the load of the equipment and the actual elongation of the chain through the hydraulic system. Operators can regulate the tightness of the chain by controlling the pressure in the hydraulic system, and during operation, the hydraulic system can also automatically adjust the tension force according to feedback from sensors, ensuring that the chain remains at an appropriate tension level.

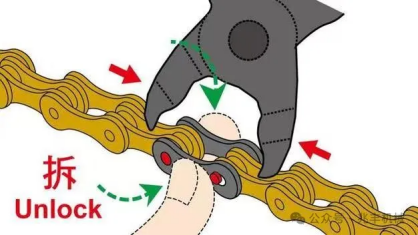

Change the chain method

When the chain is used for a long time, due to wear and elongation, it cannot be effectively adjusted by the above methods, and the wear degree of the chain has exceeded the allowable range, so it is necessary to consider replacing the chain.

When selecting new chains, ensure their specifications match the equipment requirements. After installing the new chain, make initial adjustments according to the design requirements and standard installation procedures to achieve the appropriate tension. Additionally, after putting the new chain into use, regularly check its tension and make timely adjustments.