Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 2 Author: Site Editor Publish Time: 2025-01-10 Origin: Site

How to choose the right gearbox for your application?

Gearbox is a common mechanical assembly that is commonly used in mechanical devices with rotating parts. The gearbox is composed of multiple toothed mechanical transmission components that can transfer power and increase the output torque between the machine components.

The working principle of the gear box

The motor can provide continuous output torque and speed. The motor works more efficiently and easier to control at high speed (> 1000 rpm). Design and manufacturing new motors to meet the need for torque and speed for a specific application, but changing torque and speed by replacing the gear sets in the gearbox. Usually, the motor manufacturers can provide a range of motors and gearboxes. So that designers can combine according to the application needs.

The motor shaft is connected to the first stage gear, whose output torque and speed are transmitted downward through the internal configuration of the gear. The actual output torque and speed of the output shaft after the deceleration are determined by the transmission ratio. The gearbox essentially trades in speed for torque. The output speed decreases by the transmission ratio (divided by the transmission ratio), and the output torque increases by the transmission ratio (multiplied by the transmission ratio).

Type of gear box

Many types of gearbox —— such as inclined gear, coaxial oblique gear in-line type, bevel gear, parachute gear oblique gear, right-angle type, regular gear type, planetary gear type, etc.

This paper mainly introduces the positive gearbox and the planetary gearbox.

Gear box

Positive gear is the most common gear, also known as straight gear. They have cut straight gears that are parallel to each other and engage with each other to form gear sets. In mechanical applications, the normal gear can not only lift the speed of the device, but also, when forming a series of engaged gear sets, the power is transmitted from one shaft to another, thus achieving the effect of increasing or decreasing the torque.

The positive gears engaging each other transmit the mechanical power through a parallel offset arrangement. Positive gearbox design is simple, high cost-effective, good durability, high reliability, can provide forward, constant output speed, and convenient for daily industrial operation.

Ocean Industry Provide a range of cost-effective positive gearboxes featuring sintered metal gears complementary to our motors. This combination of gearbox and Ocean Industry motor can be more flexibly applied to low-load applications. The forward gearbox is designed with an offset output shaft, equipped with sliding bearings or ball bearings. An optional lubricant can be applied to extreme temperature; nylon gear can reduce noise. In addition, the short shape structure is more conducive to customers to choose a variety of deceleration ratio in a narrow space.

The gear design of the front gear is simple, so it can meet the requirements of high precision, and it is easy to manufacture. The main disadvantage of the forward gear is the noise generated through a single tooth engagement, and the more the gear, the greater the noise. Positive gears are usually used in low speed applications but can also be used for high speed applications without considering noise concerns.

epicyclic gearbox;planet cage

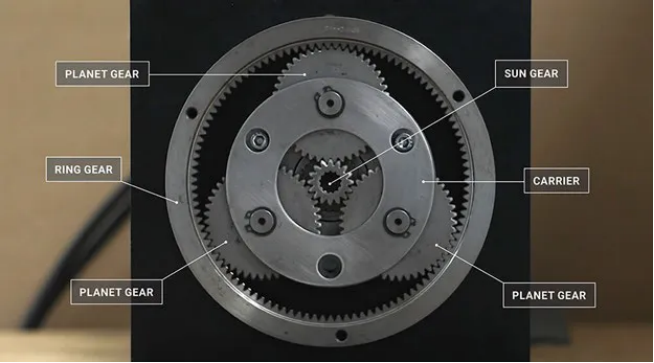

The center of the planetary gearbox is the solar wheel, surrounded by three or four planetary wheels. Each gear is synchronized with the inner teeth of the outer ring gear.

This design distributes energy evenly from several teeth on the solar wheel to various teeth on the planetary gear. Planetary gear systems provide high torque output in small spaces, so they are often used in cutting-edge technologies such as robotics and 3D printing.

Planetary gearbox is not only durable, but also has good accuracy and high accuracy. This type of gearbox can not only extend the service life of the equipment, but also optimize the performance of the drive motor. The planetary gearbox can be configured with a variety of mounting options, including dedicated flanges or shaft sleeves.

The simple planetary gear set consists of three main components:

Sun gear (center gear) + multiple planetary gear + ring gear (outer gear)

The ring gear supports the sides of the planet gear. The planetary shelf contains the solar gear or output shaft for driving the next stage planetary gear.

The central solar gear drives multiple planetary gears with a high-speed, low-torque input, which reduces the planetary frame speed and increases torque. Such a simple design enables the efficient transmission of power from the motor to the reduced output end. The single-stage gearbox can transmit more than 90% of the input power.Ocean Industry Can provide customers with a range of different transmission ratios, different levels of planetary gear. Planetary series provides a center output axis for continuous working power transmission applications of servo products. The planetary gearbox comes with plastic or metal gears and can be customized with sliding bearings or ball bearings on the input and output shafts. A primary plastic gear in the multistage gear box can reduce noise at high speeds.

Which gearbox is better for you?

Similar to the motor, choosing the gear box also needs to be careful.

There are a variety of optional gearboxes, including regular, planetary, and many other types of gear boxes, and designers should consider the following when selecting gear boxes:

Does the gearbox need to handle a continuous high-speed input?

Can the gearbox be driven by the load?

Can the gearbox withstand the required axial and / or radial heavy loads?

What is the backlash in the gearbox? Is it important for applications?

Does the selected gearbox meet the applied size limit?

The gearbox can be directly integrated with the PITTMAN motor.