Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

Industrial series lifting group rail

Product description

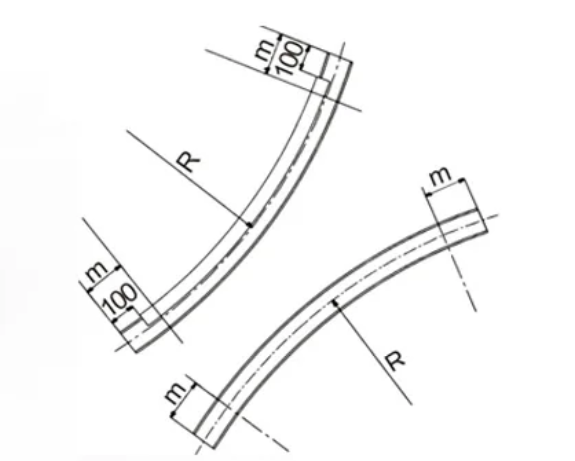

It is used at the ascending and descending points of the conveyor chain. It can be cut at any angle according to the installation site conditions, but the angle should not be greater than 45 °. However, the influence of the distance between the two spreaders connected to the ascending and descending points must also be considered.

Product Specification

Project | Track | m | R | α |

XT80 | 8# | 160 | 1500 2000 2500 | 15°; |

10# | 30°; | |||

XT100 | 12# | 160 | 2000 2500 3150 4000 5000 | 30°; |

14# | 45°; | |||

XT160 | 14# | 160 | 2000 2500 3000 3500 4000 4500 5000 | 15°; |

35°; | ||||

16# | 180 | 45°; |

Performance characteristics:

Height adjustment flexibility: Precise lifting adjustment within a certain height range to meet different workpiece coating needs. For instance, it can adjust workpieces of various heights to proper coating positions for uniform and complete coating.

Collaborative work with coating line: Cooperates with other equipment like conveyor lines and spraying devices. When a workpiece reaches the lifting group via the conveyor line, it accurately lifts or lowers the workpiece to the designated coating position and then works with spraying equipment to enhance automation and production efficiency.

Operational stability: Ensures workpiece stability during coating for quality. The structural design and drive system provide stable lifting movement, reducing vibration and shaking to avoid impacting the coating process.

Application

Automobile coating: In car manufacturing, body coating is done at different heights and angles. The lifting group on the coating line can lift the body to different stations for primer, topcoat, and clear coat.

Furniture coating: For large or complex furniture, the lifting group helps adjust to the right position for spraying, improving efficiency and quality.

Industrial equipment coating: Equipment casings and parts need coating for corrosion resistance and aesthetics. The lifting group can adjust height and angle to meet coating needs.

How to choose the appropriate lifting group rail

Load capacity:Determine by maximum workpiece weight. For heavy workpieces, choose a high-capacity one to ensure safety.

Lifting height range:Analyze as per different workpiece needs. Ensure it meets all coating requirements for comprehensiveness and uniformity.

Lifting speed:Consider production line rhythm. Fast speed if needed but not too fast to affect stability and quality.

Precision requirements:For high-precision coating, select a group with accurate adjustment.

Compatibility:Must be compatible with other coating line equipment.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: generally 15 workdays.

2.Production Lead-times: 30-60 workdays after getting your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

We'll show you the photos of the products and packages before you pay the balance.

Q4: What is your advantages?

1. Manufacturer,the most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

4. Rich stock and quick delivery.

Q5. If you can’t find the product on our website,what do you next?

Please send us inquiry with product pictures and drawings by email or other ways and we'll check.