Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

Power and free conveyor trolley

Product description

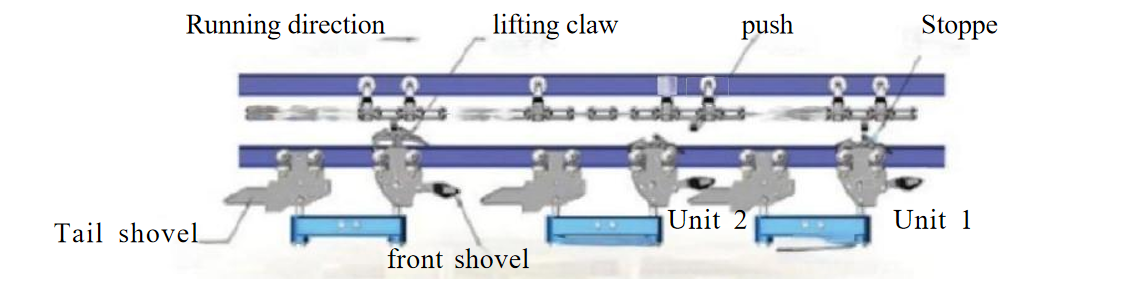

The power and free trolley set is generally composed of a front trolley, a rear trolley and a load beam. A front shovel is installed on the front trolley and connected to the lifting claw through a coupling mechanism. A tail shovel is installed on the rear trolley. When accumulation operation is required, the pneumatic stopper is opened, and the lifting claw on the front trolley of the first trolley set is pressed down to disengage it from the pusher on the traction chain, and the first trolley set stops running. The second trolley set continues to move forward until the front shovel of the front trolley rises along the inclined plane of the rear trolley of the first trolley set and drives the lifting claw to descend and disengage from the traction chain. The second trolley set stops running, and the same applies to subsequent trolley sets. When the accumulation operation is completed, the pneumatic stopper is closed. The lifting claw on the front trolley of the first trolley set is lifted by the weight of the front shovel itself. The pusher on the traction chain is in place to push the first trolley set to move forward. As the first trolley set moves forward, the front shovel of the front trolley of the second trolley set is disengaged from the tail shovel of the rear trolley of the first trolley set, and the lifting claw is lifted to complete the accumulation operation.

Product Specification

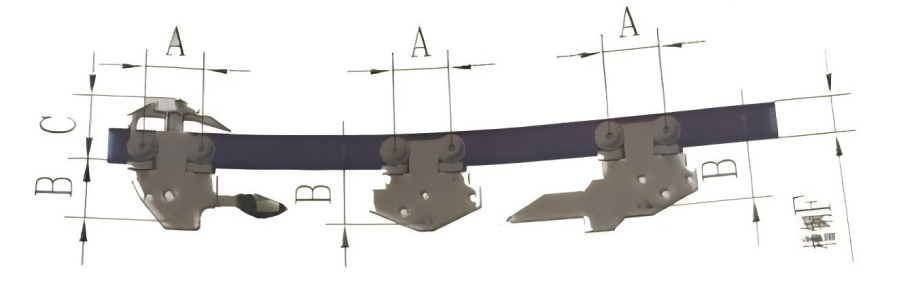

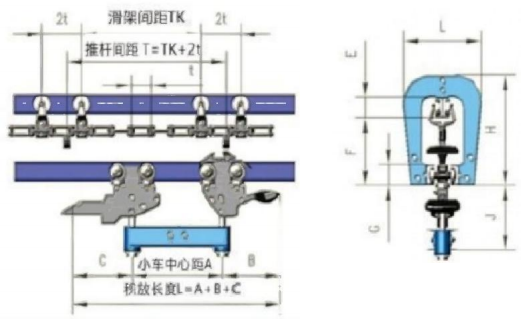

Type | Parameter | |||

A | B | C | F | |

JX3W | 105 | 125 | 138 | 80 |

JX4W | 115 | 144 | 150 | 100 |

JX6W | 190 | 220 | 163 | 160 |

Type | Parameter | ||||||||||

t | A | B | C | D | E | F | G | H | J | L | |

JX3W | 3” | Optional | 229 | 80 | 125 | 80 | 243 | 80 | 400 | 340 | Optional |

JX4W | 4” | Optional | 290 | 123 | 144 | 100 | 273 | 100 | 441 | 375 | Optional |

JX6W | 6” | Optional | 298 | 118 | 245 | 100 | 386 | 160 | 615 | 380 | Optional |

Application

Automobile manufacturing industry: Used for transporting automotive parts in stamping, welding, painting and assembly workshops, including body parts, engine blocks, doors, interiors, electronics, etc., for material distribution among different workshops and stations.

Home appliance manufacturing industry: Transports casings and internal components of home appliances like refrigerator casings, compressors, washing machine motors, etc., connects different production lines to ensure components reach the assembly station timely and accurately.

Logistics and warehousing industry: In distribution centers, it's used for transporting goods from receiving to sorting areas and accumulation during sorting, distributing goods by destination, category, etc. In warehouses, it can move goods between floors for transfer among storage, replenishment and shipping preparation areas, and adjust the transportation rhythm as per the situation.

Machining industry: Transports rough and finished products like shafts, precision gears between raw material warehouses, processing machines, quality inspection areas and finished product warehouses. It circulates among different processing procedures to ensure sequential processing and accumulates parts in case of process abnormalities to ensure production continuity.

Performance characteristics:

Efficient transportation: The vehicle group can run continuously in an automated system at preset speeds and routes, enhancing the transportation efficiency. It can work non - stop and its speed can be adjusted with the production rhythm.

Flexible production: It adapts to different processes and types. By changing the route and rules, it's used for mixed - product production. In workshops, it transports various parts with simple programming.

Precise positioning function: With advanced technology, the vehicle group can dock accurately. In assembly lines, it delivers components precisely with small errors, ensuring accuracy.

Scalability: The system is expandable. New elements can be added when production changes, like adding blocks to improve the system.

Working principle:

The accumulation and release vehicle group can realize the accumulation and release functions of vehicles. This is mainly achieved through a special accumulation device. On the conveying line, when the subsequent accumulation and release vehicle group needs to wait for the vehicle in front to complete a certain process or encounters a congestion situation, the accumulation device will stop the vehicle on the track. When conditions permit, for example, when the process in front is completed or the congestion is relieved, the vehicle can be released again and continue to move forward. This accumulation function is the result of the combined action of mechanical structures (such as blockers, push rods, etc.) and control systems (such as solenoid valves controlled by sensor signals to drive the action of the accumulation device).

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: generally 15 workdays.

2.Production Lead-times: 30-60 workdays after getting your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

We'll show you the photos of the products and packages before you pay the balance.

Q4: What is your advantages?

1. Manufacturer,the most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

4. Rich stock and quick delivery.

Q5. If you can’t find the product on our website,what do you next?

Please send us inquiry with product pictures and drawings by email or other ways and we'll check.