Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 3 Author: Site Editor Publish Time: 2025-06-30 Origin: Site

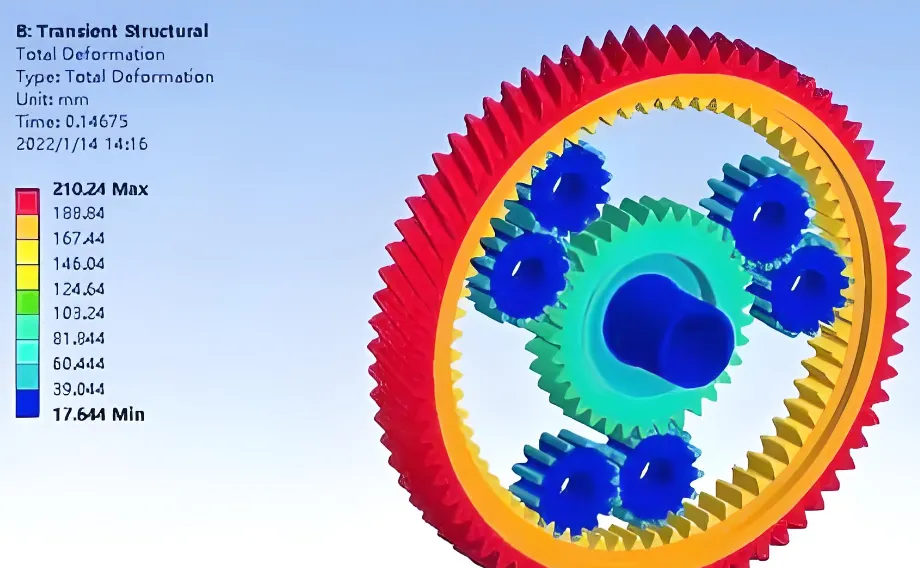

Gears are a common transmission component in machinery, and their performance directly impacts the efficiency and longevity of the equipment. However, during actual use, gears can suffer from wear and tooth breakage, leading to equipment downtime or even safety incidents. Tooth breakage primarily results from long-term alternating loads, which cause bending fatigue in the gear, leading to cracks at the root due to cyclic stress and eventual fracture. According to statistics, bending fatigue accounts for 30% to 40% of gear failures. This article will analyze the causes of gear tooth breakage and propose preventive measures to enhance the reliability and lifespan of gears.

1. Causes of gear tooth breakage

Gear fracture refers to the partial or all teeth of the gear fracture, usually caused by a variety of factors, mainly including the following aspects:

1. Design defects

A) Insufficient gear tooth strength: the load demand is not fully considered in the design of gears, resulting in excessive bending stress at the root of the teeth.

B) The gear shape parameter is unreasonable: such as the module is too small, the number of teeth is too few, the tooth width is insufficient, etc., which reduces the bearing capacity of the gear.

C) Improper material selection: the hardness and toughness of gear material do not match, which makes it easy to break under impact load.

2. Manufacturing process problems

A) Processing error: such as low tooth precision, excessive roughness of the tooth surface, resulting in local stress concentration.

The machining defect of the gear teeth leads to stress concentration

B) Improper heat treatment: the process such as quenching and carburizing is not strictly controlled, resulting in uneven internal structure or cracks of gears.

Comparison of heat treatment of different gears and materials

C) Forging or casting defects: such as porosity, slag inclusion and other internal defects, reduce the mechanical properties of gears.

3. Use and maintenance factors

A) Overload operation: the gear is subjected to impact or continuous high load exceeding the design load, resulting in fatigue fracture.

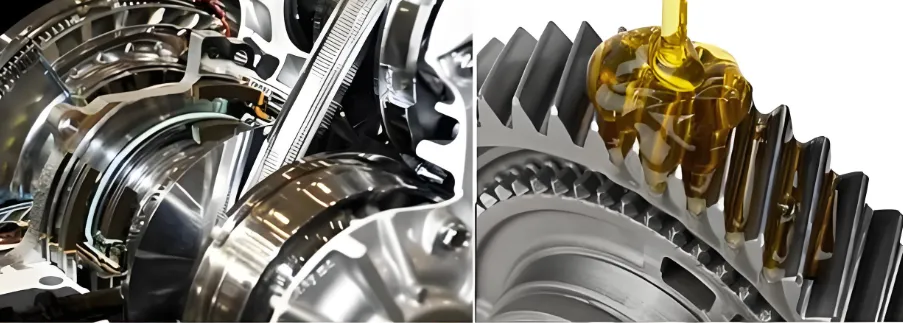

b) Poor lubrication: insufficient lubricating oil, improper selection of oil or oil pollution, aggravate gear wear and fatigue.

C) Improper installation: such as poor gear alignment, excessive axial clearance, etc., resulting in uneven local force.

D) Corrosion and wear: long-term working in a harsh environment, tooth surface corrosion or wear is serious, reducing the strength of gears.

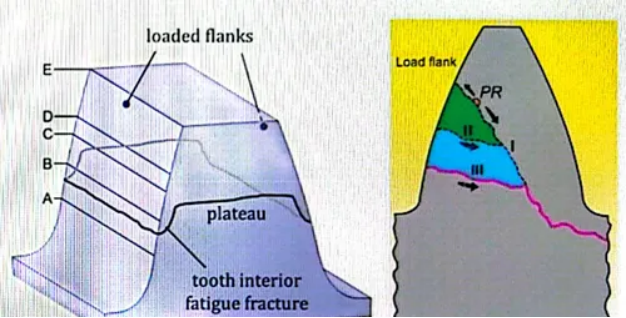

4. Fatigue fracture-focus on elaboration

The bending fatigue of gears can be viewed in the article "Summary of Knowledge on Gear Contact Strength and Bending Strength". Under long-term alternating stress, gears may produce micro-cracks, which will gradually expand until fracture. Fatigue fracture is usually manifested as a shell-shaped fracture, which is a common cause of gear tooth breakage.

a. material factor

Insufficient material strength: the bending strength of gear material is low or toughness is poor, unable to bear long-term alternating stress.

Internal defects, such as inclusions, pores, microcracks, etc., will become the starting point of fatigue cracks.

Improper heat treatment: uneven quenching, insufficient depth of carburizing layer or insufficient tempering, resulting in the reduction of root strength.

b. Design factors

The radius of the root corner is too small: the stress concentration coefficient increases and fatigue sources are easy to form.

Inappropriate modulus selection: too small modulus will lead to insufficient root section area and high bending stress.

Uneven load distribution: the gear is overloaded, misaligned or poorly engaged, resulting in increased local stress.

C. Manufacturing factors

Low processing accuracy: large tooth error, high tooth surface roughness, aggravating stress concentration.

Surface treatment defects: such as grinding burn, hobbing knife marks, etc., will reduce the fatigue strength of the root of the tooth.

D. Use of operating condition factors

Effect of alternating load: the fatigue life of gears is significantly reduced under frequent start and stop, variable speed or impact load.

Lubrication is not good: the oil film breaks down and the metal comes into direct contact, increasing local stress.

Environmental corrosion: moisture, acid medium and so on will accelerate the crack propagation.

Second, the preventive measures of gear tooth breakage

The following preventive measures can be taken to prevent the causes of broken teeth:

1. Optimize the design

A) Reasonable selection of module, tooth width and other parameters to ensure that the strength of gears meet the requirements of working conditions.

Gear parameter calculation table

B) Adopt displacement gear, shaping gear and other optimized design to reduce stress concentration.

C) Select high strength and toughness materials (such as alloy steel, carburized steel), and carry out appropriate surface strengthening treatment.

Gear design process Gear bending strength calculation table

2. Strictly control the manufacturing process

A) Improve the machining accuracy of gears to ensure the smoothness and accuracy of tooth shape.

B) Adopt reasonable heat treatment process (such as tempering, carburizing and quenching) to improve the hardness of tooth surface and toughness of core.

Conduct nondestructive testing (such as ultrasonic and magnetic particle inspection) to ensure no internal defects.

3. Strengthen the management of use and maintenance

A) Avoid gear overload operation, and use overload protection device when necessary.

B) Regularly check the quality of lubricating oil to ensure adequate lubrication and appropriate oil products.

C) Ensure the installation accuracy of gears and avoid problems of eccentric load and vibration.

D) Regularly check the wear and pitting of the tooth surface, and replace the damaged gear in time.

4. Improve fatigue life

A. Optimize gear design

Increase root radius: reduce stress concentration and increase fatigue limit (e.g., use the root transition curve recommended by ISO 6336).

Reasonable selection of modulus and number of teeth: ensure that the root of the tooth has sufficient bending section.

Shape modification design: such as tooth profile shape modification, tooth direction shape modification, improve the load distribution.

b. Select appropriate materials and heat treatment process

High strength alloy steel (such as 20CrMnTi, 20CrMo, 20CrMnMo) is hardened by carburizing or nitriding to improve the hardness of tooth surface and toughness of core.

Control the quality of heat treatment: avoid defects such as quenching crack and temper brittleness.

Surface strengthening treatment: such as shot peening, laser impact strengthening (LSP), improve the fatigue resistance of the root of the tooth, the strength can be increased by more than 1 times.

C. Improve manufacturing accuracy

Precision machining: using grinding, shaving and other processes to reduce the surface roughness (Ra<0.8μm).

Quality control: material defects are eliminated by magnetic particle inspection (MT) or ultrasonic testing (UT).

d. Improve the conditions of use

Avoid overload operation: use torque limiter or overload protection device.

Optimize lubrication mode: select high viscosity gear oil and replace it regularly (such as ISO VG 220 or 320).

Regular maintenance and inspection: monitor gear vibration, noise and tooth surface condition, and find early fatigue cracks in time.

conclusion

Gear tooth breakage is the result of a combination of factors, including design, manufacturing, use, and maintenance. To reduce the risk of tooth breakage, efforts should focus on four key areas: design optimization, process control, proper use, and scientific maintenance, all aimed at enhancing the reliability and longevity of gears. Effective prevention and management can significantly reduce the risk of gear tooth breakage, ensuring the long-term stable operation of equipment.