Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 1 Author: Site Editor Publish Time: 2024-09-27 Origin: Site

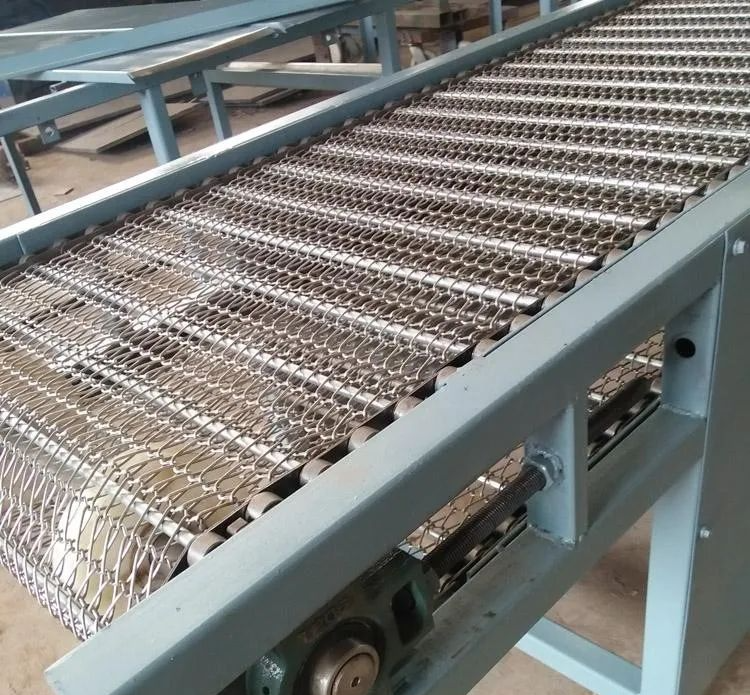

Chain conveying equipment uses chains as the main load-bearing body. Due to the large allowable length error of the chains, the wear of the chains during use can also cause the pitch of the chains to elongate. Therefore, the chain conveyor equipment must be designed with a tensioning device.

The tensioning stroke of the tensioning device is related to the pitch of the working chain and the length of the conveyor line. The design principle of the tensioning amount is to meet the allowable deviation of the chain length and allow the chain to be extended by two sections of the chain length due to wear and tear, in order to ensure that the two sections of the chain can be removed after wear and tear increases, and the conveyor can work normally to extend its service life.

The structure of tensioning devices includes spiral tensioning structures (such as flat or scale conveyors), spring tensioning mechanisms, and heavy hammer tensioning mechanisms (such as suspension conveyors).

Due to the high chain tension of chain conveying equipment, when using a spiral tensioning structure, it is important to ensure that the tensioning screw is subjected to compressive stress rather than tensile stress to meet its strength and stiffness requirements, especially when the shaft support seat of the tensioning mechanism is made of cast iron.

The support of its shaft generally adopts double row self-aligning ball bearings with sliding seats. Choosing this type of bearing seat structure, firstly, it can move on the tensioning track to meet the tensioning requirements, and secondly, the self-aligning bearings can ensure that the conveyor can work normally when there is a certain degree of coaxiality error between the two supports.

When the conveying equipment adopts a double chain or more than two chain structure, due to the fact that the lengths of each chain cannot be the same, the combination of the sprocket on the driven shaft and the shaft must not use key connection, but should allow the sprocket to move on the shaft to reduce the additional tension on the chain.