Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 4 Author: Site Editor Publish Time: 2025-04-17 Origin: Site

Gear side clearance refers to the gap between the working tooth surfaces and the non-working tooth surfaces of a gear pair, typically measured along the meshing line. For helical gears, it is measured along the meshing line perpendicular to the tooth surface. What factors usually influence gear side clearance, and what are the recommended design values for gear side clearance in general applications?

1) General principles of gear side clearance design

Gear clearance is a critical parameter in gear design. Excessive gear clearance can affect the accuracy of meshing motion or cause meshing impact (especially in reverse transmission or neutral gear situations). Insufficient clearance may lead to gear jamming due to eccentricity and manufacturing errors. For general power transmission gears, it is generally recommended to use larger clearances to ensure normal operation under the shortest center distance and worst temperature conditions, as well as under gear manufacturing and installation errors, preventing jamming. For precision control gears, smaller clearances are typically used in design to maintain the accuracy and precision of motion.

2) Factors affecting gear side clearance

The effect of center distance

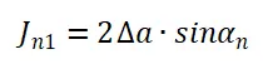

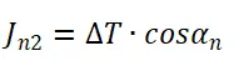

The center distance will increase the gear side clearance, and vice versa, the center distance change has the following relationship with the side clearance change:

temperature affect

Due to the difference of shell material and gear material, or the difference of temperature rise, the expansion amount of gear and shell is different, thus changing the side clearance of gear. The large expansion amount of gear will reduce the side clearance, and the large expansion amount of shell will increase the side clearance.

The effect of tooth thickness tolerance

Since the gear clearance is realized by the tooth thickness reduction, there are deviations in the tooth thickness during the manufacturing process. The change of the tooth thickness will lead to the change of the gear clearance. The thinner tooth thickness corresponds to the larger gear clearance, and vice versa, corresponding to the smaller gear clearance. The relationship between the tooth thickness tolerance and the side clearance change is as follows:

3) Recommended value of gear side clearance

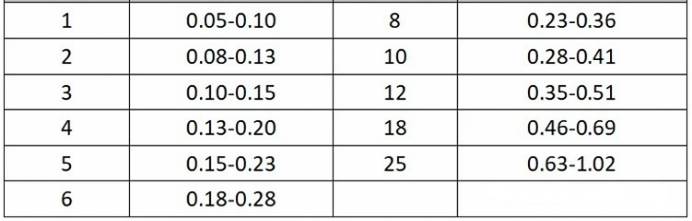

The literature provides recommended values for gear side clearance of different module sizes, applicable to straight gears and helical gears:

The data provided in the table are suitable for low speed operation and small temperature change.

Planetary gear system, in order to prevent the floating sun wheel or gear ring from floating too much when light load to cause vibration problems, should use a small side clearance;

When the expansion rate of the housing material is different from that of the gear material, or when the center distance is large, the recommended value in the table may be too small. Specific side clearance design