Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 1 Author: Site Editor Publish Time: 2025-05-16 Origin: Site

In mechanical design and manufacturing, dimensional tolerance is not only the basis for controlling part interchangeability and assembly reliability, but also the core parameter guiding the processing technology route and selecting processing methods. Different processing methods can achieve different dimensional accuracy and surface quality, so the reasonable selection of processing means is an important prerequisite for achieving target tolerance.

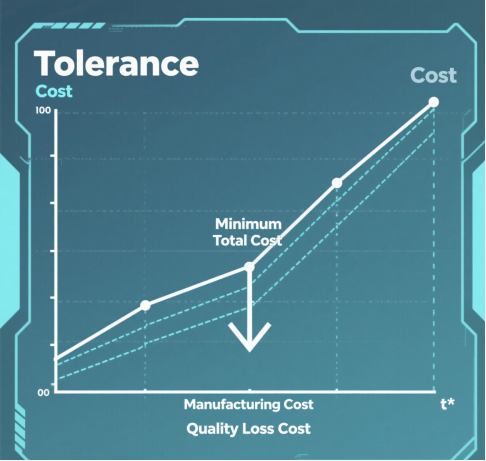

What is "economic tolerance"?

In mechanical manufacturing, it is not "the higher the precision, the better". The improvement of machining accuracy will significantly increase the processing cost and cycle, so the most economical and achievable machining tolerance should be selected on the premise of meeting the assembly and functional requirements.

Comparison of different processing methods and tolerance grades

| job operation | job operation | job operation | job operation |

| Typical achievable tolerance (IT grade) | Typical achievable tolerance (IT grade) | Typical achievable tolerance (IT grade) | Typical achievable tolerance (IT grade) |

| Surface roughness Ra (μm) | Surface roughness Ra (μm) | Surface roughness Ra (μm) | Surface roughness Ra (μm) |

| Features and applications | Features and applications | Features and applications | Features and applications |

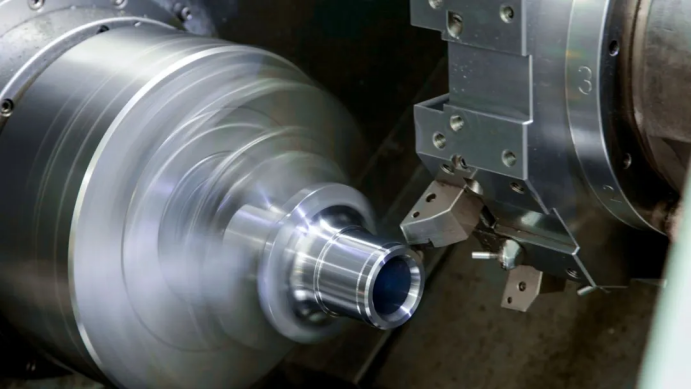

Effect of turning on tolerance

Characteristic

Suitable for rotary bodies (such as shaft, hole, step, thread)

The equipment cost is low, the operation is flexible, and the outer circle and inner hole can be coaxial

Factors affecting tolerance:

Tool wear and tip radius

Fitting accuracy (tailstock, chuck)

Workpiece material and rigidity (long shaft is easy to deform)

Effect of milling on tolerance

characteristic:

Suitable for plane, keyway, cavity, hole processing

Suitable for large parts, irregular parts, processing path free

Factors affecting tolerance:

The workpiece clamping method affects the reference repeatability

Large tool overhang length → vibration effect

Multi-axis machining center has higher precision (up to IT8)

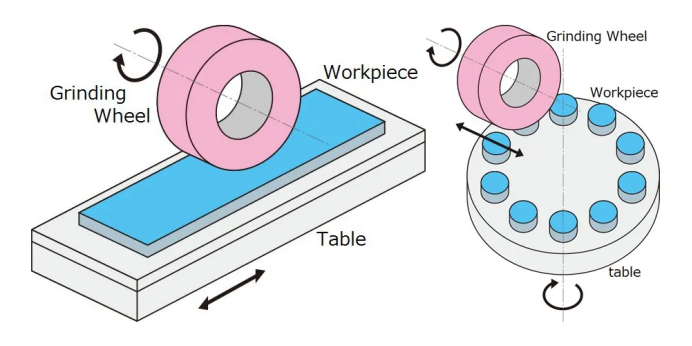

Effect of grinding on tolerance

Features: mainly used in finishing process to achieve high precision and mirror quality

Usually used for hard materials, high fitting parts (such as bearing seat, mating hole)

Achievable accuracy:

The size tolerance is IT5~IT6

Cylindricity and flatness can be controlled in 0.002~0.01mm

Surface roughness Ra ≤ 0.4μm

influencing factor:

Grinding wheel size, hardness and trimming method

Grinding heat control to avoid burns and residual stress

Coolant supply uniformity

Process selection and tolerance allocation suggestions

| grade of tolerance | grade of tolerance | grade of tolerance |

| Suggestions for processing | Suggestions for processing | Suggestions for processing |

| mode of execution | mode of execution | mode of execution |

| IT11 ~ IT13 | IT11 ~ IT13 | IT11 ~ IT13 |

| rough finish | rough finish | rough finish |

The design tolerance of the parts must match the actual machining process capability to avoid the ideal precision of "armchair talk"

The selection of machining method should be combined with part material, structural characteristics, batch demand and assembly accuracy requirements