Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 4 Author: Site Editor Publish Time: 2024-12-04 Origin: Site

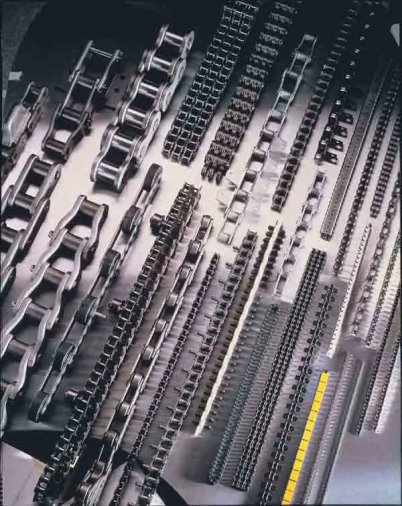

Firstly, it is necessary to correctly understand the important roles that wear resistance and fatigue resistance play in a chain, so that the breaking load or tensile strength won't become the main reasons for selection. If you understand the operation of machinery better than anyone else, you must know the principle that the operation of a chain needs to be coordinated with speed, load and operating conditions.

Under normal circumstances, the chain should not operate under any conditions close to its breaking load. If it does, it is necessary to recheck the drive settings or consider the selection of the chain.

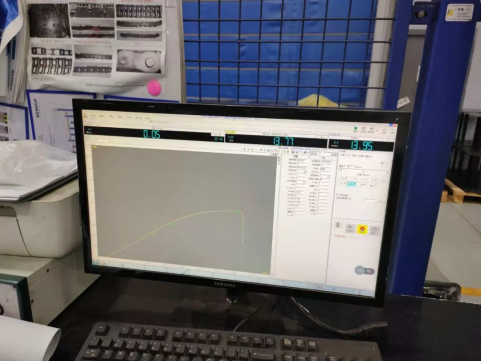

Consider the relationship between the cyclic operation amount of the chain and the load. The lower the load is, the greater the cyclic amount that the chain can withstand. If you impose a huge load, it will be sufficient to cause the chain to break. Therefore, you need to understand the normal operating load in applications and then you can select the corresponding chain. To achieve a long wear life, a crucial step is the consistency of the design of parts, material properties and the heat treatment process. Heat treatment plays a very important role in the mechanical strength of parts and also serves as a balancing factor. Excessive heat treatment can achieve higher tensile strength, but it will also make the parts brittle and prone to fatigue failure.

To maintain a long working life of the chain, it is essential to attach importance to providing fatigue resistance that is higher than the rated working load in applications. Reliable chain manufacturers should clearly know the fatigue limit of their products, and engineers should also take this factor into consideration instead of the breaking load. Therefore, let's put the breaking load aside. The operation of the chain should be far below the breaking load. In fact, only when the load on the chain far exceeds the elastic limit of the steel will it cause permanent damage. The chain should operate below its own endurance limit to ensure that wear is the cause of chain failure, rather than fatigue or overload.

▲abrasion

▲tiredness

▲Overload fracture

The same is true for car tires. They all need to be replaced when they have been worn out to a certain point rather than suddenly failing. Chains also need to be replaced when they are worn to a certain extent. Therefore, the crucial decision is to choose the right chains that can reach the wear level over the longest period of time.