Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 2 Author: Site Editor Publish Time: 2025-04-22 Origin: Site

In the mechanical assembly structure, pin connection (Pin Connection) is one of the most commonly used precision positioning means. It is widely used in heavy equipment, gearboxes, couplings, machine tool benchmarks and other fields because of its advantages of simple structure, convenient manufacturing and reliable installation.

Different types of pins are responsible for different tasks. Some are pure positioning, some are subjected to shear force, and some are both anti-rotation and structural fixation. This paper will systematically explain the classification, function and tolerance matching principle of pins, especially how to improve their positioning accuracy and reliability through tolerance control.

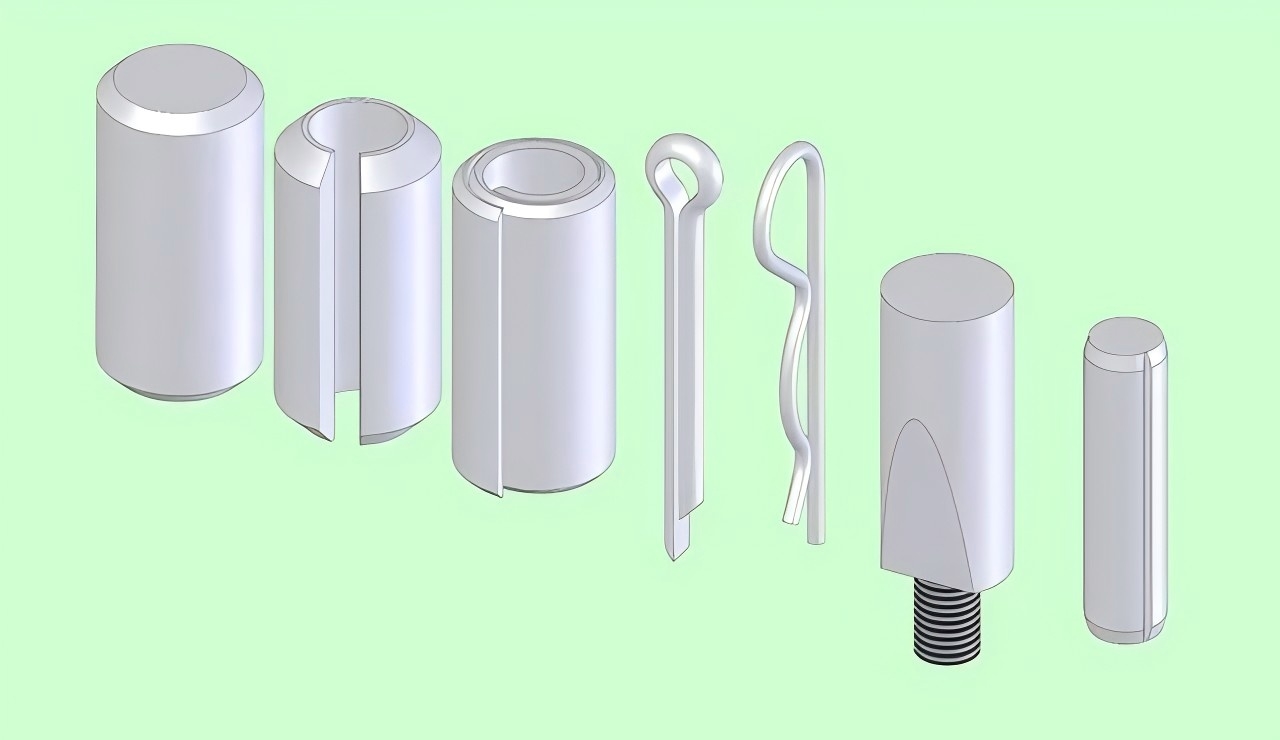

Common types and functions of sales

Cylindrical pin (Dowel Pin)

It is often used as a high precision positioning reference, and the mating hole is H7/m6 or H7/n6

It is not easy to disassemble and is often used in semi-permanent positioning structures

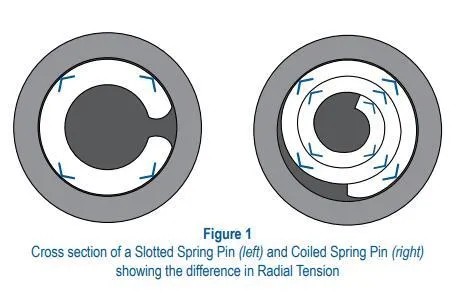

Elastic cylindrical pin (Spring Pin)

The hollow structure is elastic, easy to install and can withstand slight vibration

Suitable for medium and low load, recommended to be combined with H8/h9

Cylindrical pin (Taper Pin)

The taper is usually 1:50 and has a self-locking effect

It is mainly used for anti-rotation and anti-loosening structures

Worm gear (Split Pin)

The nut is usually used for anti-loosening, not for positioning

Location pin (Locating Pin)

The structure can be cylindrical or special orientation type

It is often used in precision tooling fixtures and the tolerance is strictly controlled

Key points of design of cooperation tolerance for the connection

✅ For high precision locating pins:

Common fit: H7/m6, H7/k6

The axial insertion force should be controlled at 0.01~0.03 mm interference

Processing method: grinding or precision milling

✅ For easy assembly structures:

Suggested fit: H8/h9, H9/h9

The installation efficiency is improved, but the positioning accuracy decreases

✅ For elastic pin/spring pin:

Recommended for support: H8/h9 or H9/h10

The mounting hole should be deburred and lightly lubricated·

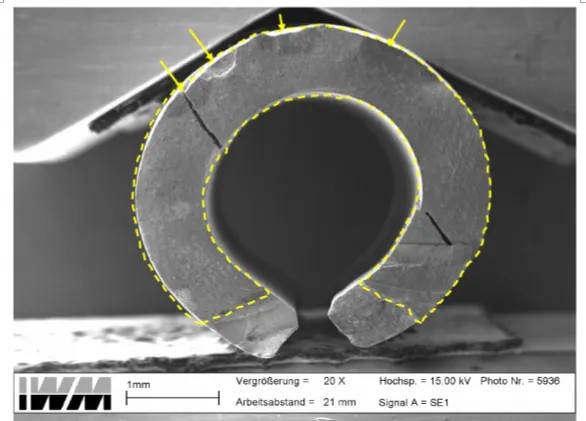

4. Comparison and analysis of fatigue strength of pins

In different types of sales structure, there are significant differences in fatigue performance. The following is the comparative conclusion obtained through a number of experiments:

Conclusion: In the scene with significant fatigue load, the reinforced solid pin structure should be selected first to significantly improve the connection life.

Installation suggestions and inspection methodsLocation hole machining suggestion: chamfer 0.5 x 45 at both ends

Test method: use pin gauge or cylindrical gauge to test the hole diameter + tolerance band

Anti-corrosion measures: apply light rust preventive oil before pin installation

When using locating pins to align holes: it is recommended to use a combination of drilling, reaming, boring and grinding

The connection tolerance must be classified according to the positioning accuracy and load conditions

Spring pins are suitable for medium vibration and easy disassembly, while solid pins are suitable for parts with high fatigue strength requirements

Different types of sales should clearly mark the tolerance and fit grade in the design stage

Fatigue failure is the key control point of locating pin design, and fatigue life assessment should be carried out