Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 1 Author: Site Editor Publish Time: 2025-06-05 Origin: Site

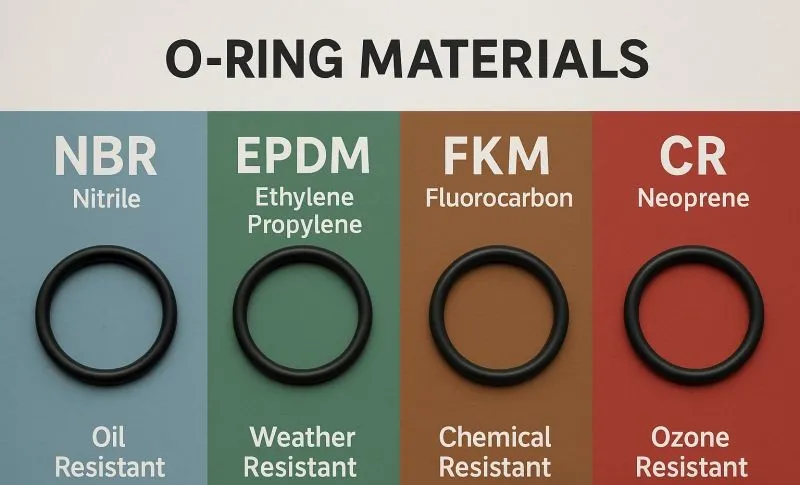

Nitrile rubber (NBR) is an elastomer made from acrylonitrile and butadiene, known for its excellent resistance to oil and fuel. However, due to the presence of carbon-carbon double bonds in its structure, it is susceptible to degradation by heat, oxygen, ozone, and strong chemicals, making it unsuitable for many pump and valve applications. Nitrile rubber operates effectively in a temperature range of-40°C to +100°C (up to 120°C for some grades), performing best in sealed oil-based systems. It is particularly suitable for static seals in components like solenoid valves and pneumatic parts, where minimal movement is required.

Fluororubber (FKM) excels in resisting chemicals, oils, fuels, and high temperatures. Thanks to its strong carbon-fluorine bonds, it can easily withstand heat, oxidation, and UV exposure. Fluororubber operates effectively within a temperature range of-20°C to +250°C (up to 300°C for some grades), making it ideal for dynamic seals in pumps, valves, and gaskets. However, it is important to avoid steam! When steam enters fluororubber, it condenses into water inside, causing the rubber to swell and harden over time, much like an old sponge. During maintenance, you may need to remove it piece by piece, as it is nearly impossible to remove it intact at once!

Ethylene Propylene Diene Monomer (EPDM) rubber is a versatile synthetic rubber known for its excellent heat resistance, ozone resistance, UV resistance, and weather resistance. It is typically vulcanized using peroxide to crosslink the rubber, enhancing its strength in high-temperature and outdoor environments. EPDM rubber can operate within a temperature range of-40°C to +150°C, making it ideal for applications involving water, steam, and weak acids. However, EPDM rubber must never be used in oil, fuel, or hydrocarbon substances. Exposure to these substances will cause it to swell, soften, and degrade faster than a banana in a heat wave. You certainly wouldn't want to use it for sealing high-performance machinery! During major overhauls, you might find yourself peeling off the rubber like removing gum from your shoe sole, and —— this is definitely not a quick or easy task!

Chloroprene rubber (CR Neoprene) is highly resistant to weather, ozone, UV radiation, and moderate chemicals. It is vulcanized with peroxide, which makes it durable for static sealing applications. Chloroprene rubber operates within a temperature range of-40°C to +120°C, making it ideal for mild chemicals and outdoor use. However, it performs poorly in pumps or valves. When exposed to oil, fuel, or high temperatures, it can swell, soften, and degrade. It has poor resistance to wear and tear, making it unsuitable for dynamic environments. However, it performs well in electrical enclosures, making it ideal for gaskets and low-pressure seals —— although if used in a pump, you will end up peeling it off like a stubborn sticker!