Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 3 Author: Site Editor Publish Time: 2024-11-11 Origin: Site

Chapter One: What is a Planetary Gear?

A planetary gear is an epicyclic gear that consists of a central gear, referred to as the sun gear and serves as the input gear, which has three or more gears that rotate around it that are referred to as planets. The planet gears engage with a ring gear that encircles the sun and planet gears and has the shape of an internal spur gear. The design of planetary gears makes them exceptionally sturdy and easy to convert to different gear ratios.

Chapter Two: How Planetary Gears are Made

Planetary gear sets are a method for converting reciprocating motion to rotary motion. They were developed by William Murdoch in 1781 for use with steam engines as a replacement for cranks that were used to produce rotary motion. A common application for planetary gears is the reduction of speed in a limited space.

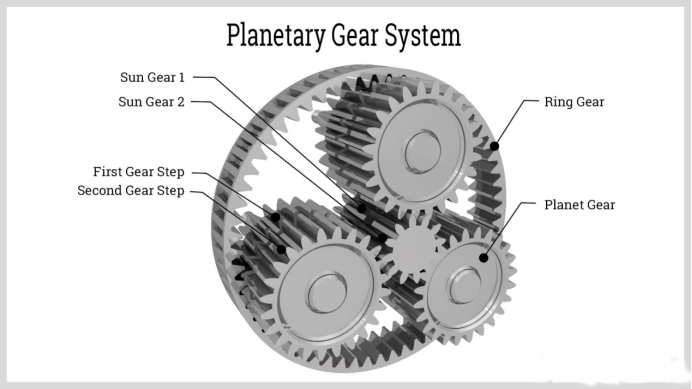

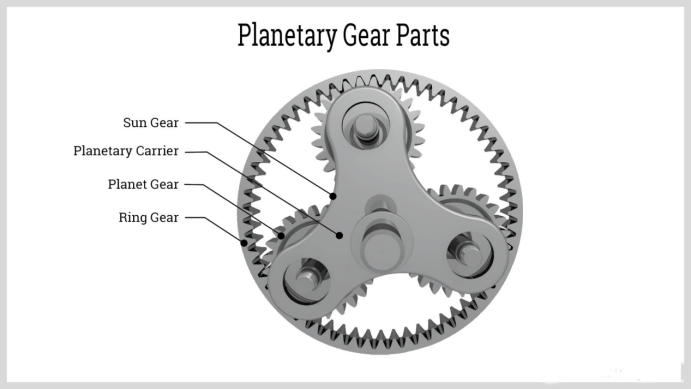

The main and essential components of a planetary gear are the sun gear or central gear, several other gears known as planets, an outer ring gear, and a planet carrier. The four components of a planetary gear provide stability because of the even distribution of mass and rotational stiffness. Torque is applied radially to the gears and transferred radially without placing pressure on gear teeth.

Sun Gear

The sun gear is the central gear in a planetary gear set that receives input for the gear set. As the sun gear is driven by the input shaft, the planet gears are empowered to drive the ring gear. The structure of a planetary gear is configured such that the pinions of the carrier, which is attached to the planet gears, are meshed with the sun gear.

Planet Gears

The planet gears are mounted on a carrier and move in accordance with the motion of the sun gear. As they rotate against the sun gear, their teeth mesh with the teeth of the ring gear. As the planet gears move, they rotate around the sun and ring gears Planetary gears have one or more planet gears and control the speed of the transmission of power.

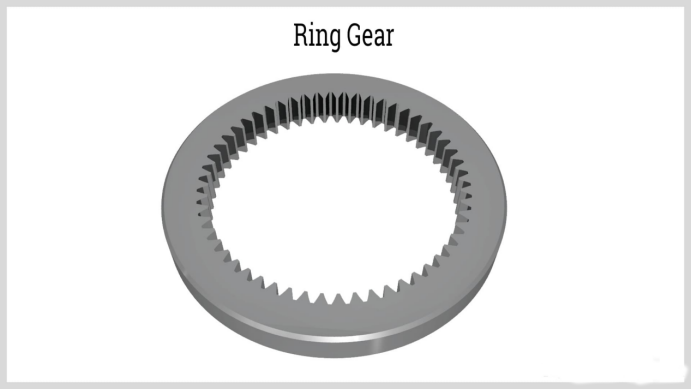

Ring Gear

The outer ring of a planetary gear system is the ring gear or annulus gear. it has teeth on its inner circumference and is smooth on its outer edge. The teeth of a planetary ring gear are pointed inward to mesh with the planet gears. The carrier and planet gears are bound and surrounded by the ring gear that is fixed in its position. All of the teeth of the planet gears mesh with the sun gear and ring gear, As the planet gears rotate around the sun gear, the ring gear is forced to rotate in the same direction as the sun gear.

Carrier

The planet gears are fixed to a carrier that connects their centers with the sun gear and ensures that they mesh such that their pitch circles roll without slippage. Normally, the carrier is movable and rotates relative to the sun gear. it is connected to the centers of each of the planet gears to provide support. The simplest form of planetary gear has one sun, one planet, a ring gear and one carrier. Compound planetary gears have more than one of each of the various gears, which become more complex as

the number of planet gears increases.

Planetary Gear Construction

Planetary gears require the defining of multiple inputs to get a specific output, The sun gear is in the center of the assembly and meshes with the teeth of the planet gears, which are small and connected to the carrier framework that is made of aluminum,cast iron, or steel. The carrier has a shat for each of the planet gears that surround the sun gear and are surrounded by the ring gear.

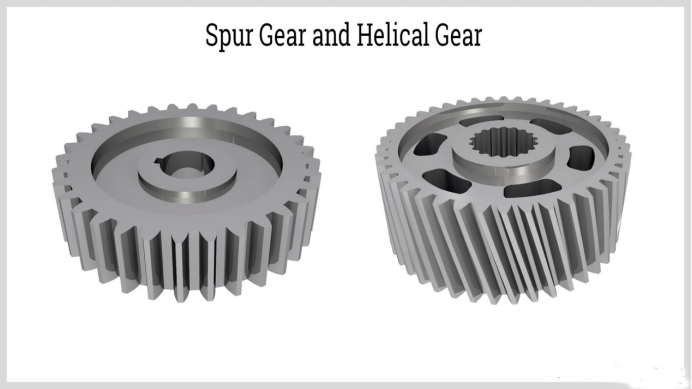

The construction of a planetary gear set can include spur or helical gears. The difference between the two gears is their helix angle with spur gears having a zero-helix angle while helical gears have a helix angle of 10 to 30 degrees. With either form of gear bearings play an important part in a planetary gear set's torque transmission. Needle bearings have the right size but are unable to tolerate the axial forces. The ideal type of bearings are tapered roller bearings for axial forces and are larger than needle bearings.

Chapter Three: Types of Planetary Gears

The various types of planetary gears are separated by their performance, efficiency, and versatility. Each type has the ability to change two inputs into a single output, a factor that makes them complicated to design and analyze. The most common form of planetary gear set is a single sun and single planet with a carrier and outer ring gear.

Planetary gear sets behave counterintuitively, a factor that makes their analysis difficult, vet intriguing and interesting. They provide excellent torque with appropriate stiffness and little noise in a compact footprint. Planetary gears come in a wide variety of forms and designs, which is one of the reasons for their wide use.

A short list of planetary gears includes:

Single-stage

Multi-stage

In-line

Offset

Coaxial

Right angle

Harmonic drive

Differential

Simpson

Ravigneaux

These ten planetary gear sets are a very small sampling of the complete list of planetary gears, which includes specialty gears designed for unique and unusual applications. It is important to note that each type of planetary gear set has its advantages and disadvantages. Their use is determined by how they meet the needs of an application.

Single-Stage Planetary Gear Set

A single-stage planetary gear set consists of a sun gear, three planet gears, a carrier, and the ring gear. The input shaft rotates the sun gear, which causes the planet gears to rotate the carrier and the output shaft. Different sized gears with different numbers of teeth change the speed and torque of the output, Single-stage planetary gear sets are used with heavy machinery, industriar equipment, and automotive transmissions. As with most planetary gears, single-stage planetary gears are used for their compact design and weight.

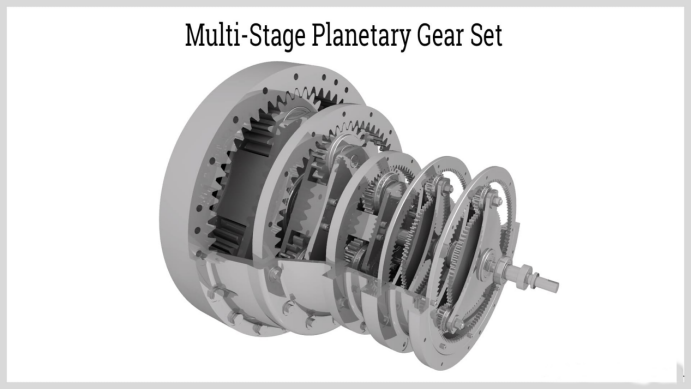

Multi-Stage Planetary Gear Set

Multi-stage planetary gear sets have two or more planetary gears to achieve the required speed and torque. They have the same construction as single-stage planetary gear sets but have several more gears added to the input shaft in the first set, which is connected to the sun gear of the first set. The carrier for the first set is connected to the sun gear of the second set, a pattern that continues to all planetary gears in the multi-stage planetary gear set, Multi-stage planetary gear sets are used in applications that require high torque and several output speeds. They achieve high gear ratios in a compact lightweight package.

In-Line Planetary Gear Set

With an in-line planetary gear set, the input and output shafts are in a straight line and consist of a single sun gear and multiple planet gears contained in a ring gear. The planet gears are mounted on a carrier, which rotates around the sun. The input shaft rotates the central sun gear, which turns the planet gears that mesh with the ring gear, he rotation around the central axis sends power to the output shaft. in-line planetary gear sets are used for their efficiency, torque density, and low backlash.

Offset Planetary Gear Sets

Offset planetary gear sets are known as parallel shaft planetary gears. They have the input and output shafts placed in an offset or parallel position. As with in-line planetary gear sets, offset planetary gear sets have a sun gear with several planet gears mounted on a carrier that mesh with the outer ring gear. instead of the output being in a straight line with the input, it is aligned differently in relation to the input shaft., Choosing the correct diameter and number of teeth of the idle gear makes it possible for the input and output shafts to be on a common axis.

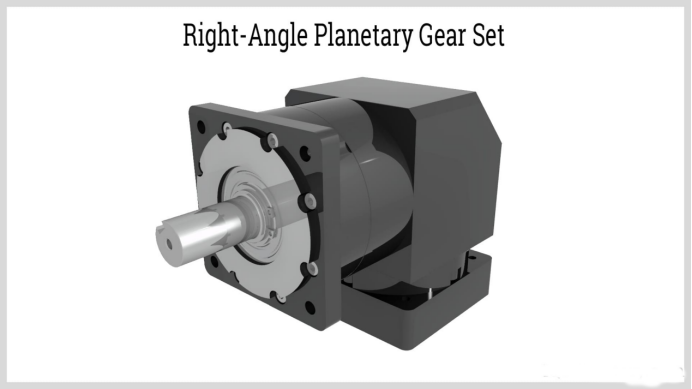

Right-Angle Planetary Gear Sets

With right angle planetary gear sets, the input and output shafts are arranged at right-angles to each other. The sun gear, planet gears, carrier, and outer ring are all mounted in the same configuration as the other gear sets. The rotation of the planet gears transmits power to a right-angle bevel gear set that is connected to the output shaft.

Harmonic Drive Planetary Gear Set

Harmonic drive planetary gear sets are also known as strain wave gearboxes and wave generator gearboxes. They use a flexible metal cup and circular spline to transfer torque. The components of a harmonic drive planetary gear set are the circular spline and the flexible cup that is referred to as a wave generator. Additionally, the gear set has elliptical or circular gears called flexspline.

The input shaft drives the wave generator that causes it to deform and create waves that move along the circumference of the cup. The created waves engage the teeth of the flexspline that rotates around the central axis of the harmonic drive gear set. The flexspline meshes with the outer ring gear that sends power to the output shaft. Harmonic drive planetary gear sets have zero backlash, high precision, and high torque density, which makes them ideal for applications where accuracy and repeatability are

important such as robotics and automation applications

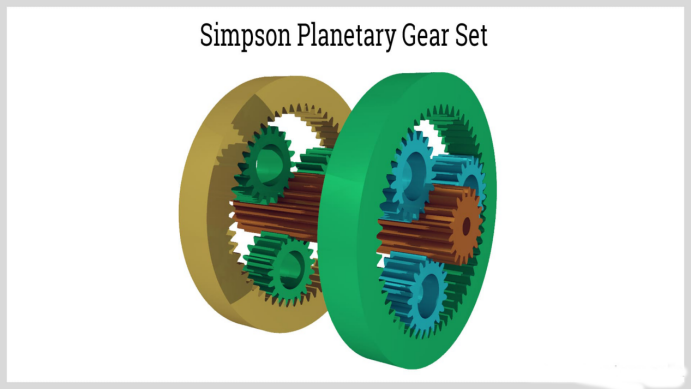

Simpson Planetary Gear Set

A simpson planetary gear set has a single sun gear and two or three sets of planetary carriers that are connected in a series. The structure of a simpson planetary gear set has three forward gears, one reverse gear, a neutral, and is used in a three or four ratio automatic transmission. the gear set is named for Howard Simpson, a famous innovator of designs for the automotive industry.

The two sets of planet gears are interdependent due to having a common sun. The first gear set is closer to the input shaft and is synchronized with the second gear set's ring.

Ravigneaux Planetary Gear Set

A Ravigneaux planetary gear set is an improvement of the Simpson planetary gear set and consists of two sun gears, two ring gears, and two sets of planet gears on a single carrier, which makes the Ravigneaux planetary gear set smaller, lighter, and less expensive. The two suns are centrally located along a common rotating axis and are of different sizes.

The process for a Ravigneaux planetary gear set involves having the smaller of the sun gears engaging its set of planets that engage the outer ring gear. The larger outer ring gear is connected to the planets of both planetary gears and engages the larger of the two suns. A carrier, with a different radius, holds the sets of planet gears in place and is connected to the drive shaft. It turns as a unit in relation to the sun and ring gears

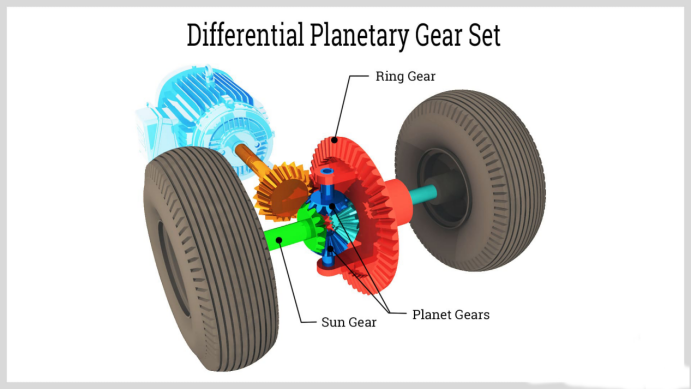

Differential Planetary Gear Set

With a differential planetary gear set, every gear rotates, which is a key factor in the gear set for driving the wheels of a car.Initially, cars were set up to have one of the wheels driven while the other wheel was mounted freely. Although it was an effective driving method, it was unsafe, which required finding a method to drive both wheels

The development of the differential planetary gear set required that each wheel have its own drive shaft. several bevel gears with a carrier are used to change the direction of the rotation of the drive shaft, The gear set has a large ring gear, a carrier, two planet gears, and a sun gear. The ring gear is connected to the shaft of one of the wheels while the sun gear is attached to the other wheel, which makes it possible to change the rotation of the drive shaft to drive the wheels.

Planetary Gearboxes

Planetary gearboxes are energized by hydraulic motors, electric motors, or combustion engines. They are the most common form of gearbox and are connected directly to a precision motor or are integrated. Planetary gearboxes are exceptionally efficient in transmitting energy from a motor to an output.

Wheel Drive

A wheel drive planetary gearbox is the simplest form of gearbox and can be connected directly to a wheel with wheels being combined over the housing of the system. The carrier for a wheel drive planetary gearbox is located in the gearbox. The direct connection of the gearbox to the wheels helps reduce the size of the gearbox.

Shaft Output

As with other planetary gearboxes, the sun gear rotates the planets, which are housed in a carrier inside the shaft drive gearbox.The ring gear is fixed while the carrier rotates the drive shaft. The housing of the gearbox is affixed directly to the machine with the output being the rotating shaft.

Spindle Output

Spindle output gearboxes are just like shaft output gearboxes with the main difference being the output delivered by a flange