Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 3 Author: Site Editor Publish Time: 2024-11-18 Origin: Site

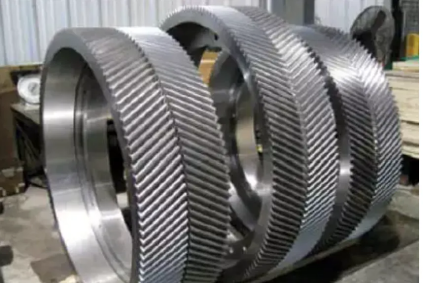

Hello everyone. In this episode, let's talk about an interesting form of gears: herringbone gears, sometimes also called double helical gears. Herringbone gears became popular in the late 19th and early 20th centuries, especially in heavy machinery, industrial equipment, and transportation systems. It is composed of a combination of "two" helical gears with the same helix angle, one with a left-hand helix and the other with a right-hand helix. The teeth are arranged in a "V" shape and are used to transmit motion and power between parallel shafts, as shown in the following figure:

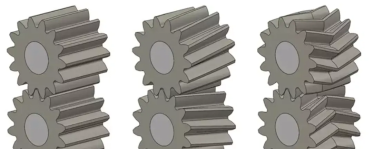

Several Forms

As shown in the following figure, three different arrangements are listed below. Only the ones without a relief groove in the middle are considered to be "true" herringbone gears.

Why use herringbone gears instead of spur gears or single helical gears?

1.Increasing Load-carrying Capacity

Herringbone gears have a distinct advantage over spur gears - they can withstand higher loads. The unique tooth profile design of herringbone gears enables them to distribute the load more evenly on the teeth, thus enhancing the load-carrying capacity and improving efficiency.

2.Reducing Vibration and Noise

One of the main drawbacks of spur gears is the presence of axial thrust, which can cause vibration and noise during operation. In contrast, herringbone gears feature a symmetrical design that can offset the axial thrust, resulting in smoother and quieter gear operation.

3.Improving Contact Ratio

The contact ratio refers to the number of teeth in contact at any given moment. Herringbone gears usually have a higher contact ratio than spur gears. This increased contact ratio ensures a more even load distribution and reduces the risk of tooth failure, making herringbone gears suitable for high-speed and high-torque applications.

4.Enhancing Lubrication

Proper lubrication is crucial for the smooth operation and service life of gears. Compared with spur gears, herringbone gears have better lubrication characteristics. The double helical design promotes better oil flow, ensuring effective lubrication between mating surfaces and reducing the likelihood of premature wear or damage.

5.Improving Efficiency

Since herringbone gears can withstand higher loads and minimize vibration, they have a higher overall efficiency compared with spur gears. This efficiency means reduced power loss and improved performance, making them an ideal choice for applications where efficiency is of utmost importance.

6.Greater Misalignment Tolerance

In some applications, misalignment between gears is inevitable. Compared with spur gears, herringbone gears are better able to handle misalignment. The symmetrical tooth arrangement helps to compensate for slight misalignments, ensuring smooth gear meshing and preventing premature wear. The elimination of axial thrust makes herringbone gears highly suitable for applications that require efficient power transmission without the drawbacks of excessive axial loads and wear.

Application Areas

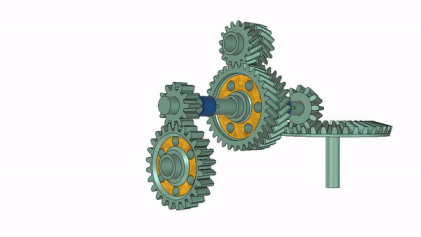

Herringbone gears are widely used in different industries. For example:

1.Mechanical Transmission:

Herringbone gears are often used in mechanical power transmission systems that require large

torque and high rotational speeds. They can ensure efficient power transmission and reduce vibration

and noise.

Applications include gearboxes, reducers, and heavy machinery that require reliable and smooth

motion transmission.

2.Industrial Equipment:

Herringbone gears are used in industrial equipment such as rolling mills, extruders, and heavy-duty conveyors. These gears can withstand large loads and provide precise motion control, contributing to the efficient operation of the manufacturing process.

3.Automotive:

In automotive applications, herringbone gears are used in differentials to transmit torque from the

engine to the wheels while enabling smooth turning. Their function of eliminating axial thrust can

minimize wear and improve durability.

Herringbone gears are also used in automotive transmissions that require high torque and efficient

power transmission.

4.Aerospace:

Herringbone gears are used in aerospace systems such as helicopter gearboxes, where high reliability and torque transmission are of crucial importance. They contribute to the stable operation of rotor systems and other key components.

5.Marine Industry:

Herringbone gears are used in marine propulsion systems, including those of ships and boats' engines. They can meet the requirements of propeller torque transmission while ensuring reliable and vibration-free operation.

6.Mining and Construction Equipment:

Herringbone gears are commonly found in heavy machinery used in mining and construction, such as excavators, bulldozers, and cranes. They provide the necessary strength and load-carrying capacity for these demanding applications.

7.Power Generation:

Herringbone gears are used in power generation equipment, including turbines and generators. They effectively transmit the rotational motion to the generators, contributing to reliable power generation.

8.Printing and Paper-making Industries:

Herringbone gears are used in printing presses and paper-making equipment to precisely control the paper feeding and cutting mechanisms. Their smooth motion transmission improves the printing quality and production efficiency.

9.Robotics and Automation:

In robotics, herringbone gears play a role in robotic arm and manipulator systems, where precise motion control is crucial for tasks such as assembly, welding, and material handling.

Herringbone gears are valued for their ability to transmit high torque, reduce axial thrust, and provide smooth meshing. Their roles in various industries highlight their importance in achieving efficient and reliable operation in a wide range of applications.