Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 2 Author: Site Editor Publish Time: 2024-10-17 Origin: Site

Strength calculation is complex

Due to the special tooth profile of fine and high tooth gears, their strength calculation method is different from traditional gears. It is necessary to consider the influence of factors such as tooth height, tooth shape, and coincidence, and adopt more complex calculation models and methods.

High processing difficulty

The processing difficulty of fine high tooth gears is relatively high, requiring the use of high-precision processing equipment and advanced processing technology. The consequence of a high degree of coincidence is that the starting circle of the involute is located lower, close to the base circle of the gear, and faces many challenges during gear hobbing, grinding, or honing, which puts higher demands on equipment and cutting tools.

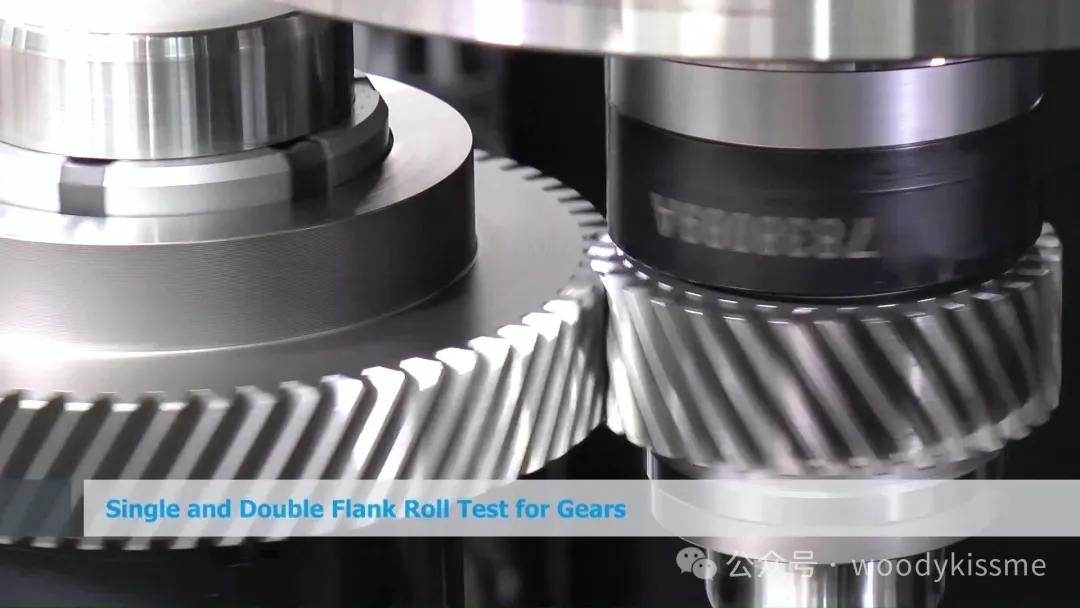

High testing requirements

Due to the high precision requirements for fine and high tooth gears, higher demands have been placed on detection equipment and methods. Precision measuring instruments such as coordinate measuring instruments, gear measuring centers, meshing instruments, etc. need to be used to detect the tooth profile, size, accuracy, etc. of the gears to ensure that the quality of the gears meets the requirements.