Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 2 Author: Site Editor Publish Time: 2025-02-11 Origin: Site

Process hole sprocket is a common kind of sprocket in mechanical manufacturing. With the birth of more and more mechanical equipment, they have different requirements for sprocket. Therefore, in order to adapt to different equipment, the process hole sprocket is born with the trend.

chain wheel

Sprocket is a wheel with teeth, belongs to mechanical transmission parts. Its tooth profile is specially designed, the main purpose is to engage with the chain, so as to realize the transfer of power, the transmission of movement and other functions. In appearance, the sprocket is generally a circular disk-like structure, with a series of teeth evenly distributed at its edges. Some sprockets also highlight a piece from the side, namely the hub. In short, the shapes of the sprockets are designed to adapt to different equipment and chains.

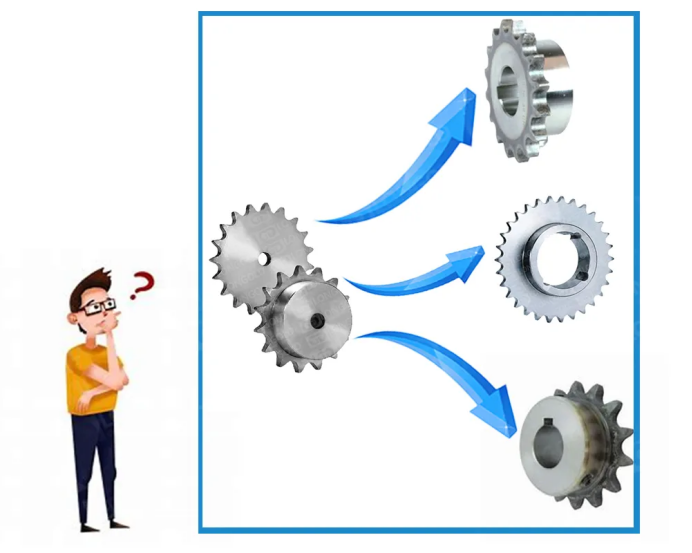

There are many kinds of sprockets, and the process hole sprocket is one of the most important sprockets that can be chased."Process holes" refers to the holes in the sprocket set up for the process requirements, which are usually used to locate, assemble, or reduce the weight of the sprocket during processing. Compared with the finished hole sprocket, the process hole sprocket has the possibility of reprocessing. In order to apply to different equipment, different tracking processing is carried out to form a special finished hole sprocket and adapt to more equipment.

Why are there process hole sprockets?

What if I don't know what kind of holes the sprocket needs to make to fit with the shaft? Or the supplier doesn't know which holes the sprocket the customer needs.

Sometimes, we don't know what need hole sprocket, such as some buyers, some of their equipment parameters confidential, or some equipment need to field detection to determine the parameters of the hole, when you need to buy sprocket from manufacturers, you can choose to buy process hole sprocket, buy from suppliers process hole sprocket, get back after processing, which won't leak don't want to disclose parameters, can also directly to a field matching equipment.

Common chase processing of process hole sprocket

Generally speaking, the process hole sprocket will be used, basically are special (that is, non-standard) sprocket. However, the hole chase processing is basically not out of the common shape.

1 Key slot

The more common is the keyway, different equipment used in the sprocket needs different keyways. Usually what kind of keyslot to do what kind of tool to chase processing.

2 Hole shape

More common hole shape has the straight hole and cone hole, according to the equipment to determine the shape of the hole.

Taper hole chain wheel

3. Add parts to the hole

Sometimes in order to adapt to the equipment, the sprocket hole will also be equipped with some other parts, such as couplings, couplings, etc.

Branding bearing chain wheel

END

We have experienced personnel to meet your customized requirements. If you have any needs, you can send an email to contact us below, and we will reply to you as soon as possible.