Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

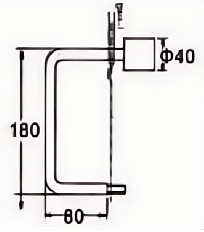

C shaped spreader

Product description

This spreader is specifically designed for paint baking factories with relatively high requirements. An oil receiving groove can be installed in the middle to prevent dust from falling on the workpiece. The size can be customized according to customer requests.

Structural Features:

The C shaped structure, made of high - strength alloy steel with ingenious design, reduces dead weight while ensuring strength, making the spreader more flexible during operation. The open C shaped is convenient for loading and unloading goods and better adapts to items of different shapes and sizes, improving operation convenience. For the light closed - track system, key components like the spreader's walking wheels are precisely designed. Made of high - quality wear - resistant materials, they have good guidance and low friction, running smoothly on the track to reduce noise and wear. The compact connection between the spreader and the track prevents derailment and other safety hazards.

Material characteristics:

Its main structure often employs high-strength alloy steel. This material choice is due to considerations of strength and load-bearing capacity. High-strength alloy steel offers outstanding load-bearing capacity for the spreader. This material can endure enormous tensile and compressive forces, ensuring that the spreader will not deform or be damaged when lifting and moving heavy loads. This is of utmost importance for maintaining the structural stability of the spreader. In practical operations, the spreader must reliably carry the weight of the cargo to prevent any potential safety hazards.

Working Principle:

Its lifting mechanism is powered by an electric motor. Transmitted through a reducer to the wire rope drum for power conversion, the hook can be raised or lowered to handle goods. The lifting speed can be controlled by adjusting the motor's rotational speed. The spreader moves on the light - duty track via walking wheels. The driving system powers the wheels to rotate and generate thrust, and the precise design of the track and wheels ensures accurate movement.

Advantages

①Powerful lifting capacity: The C-type spreader can carry heavy loads. Whether it is large parts in mechanical manufacturing or some medium-sized structural materials in the construction industry, it can reliably complete the lifting task and effectively meet the weight requirements in production operations.

②Excellent adaptability: It fits well with the light-duty track. Specifically designed for the light-duty track, the walking mechanism and connection parts of the spreader are perfectly matched with the track specifications. When the walking wheels run on the track, they fit closely and smoothly without any jamming or shaking phenomena, ensuring stable operation of the spreader on the track.

③Adaptation to various track layouts: This spreader can adapt to different forms of light-duty track layouts. Whether it is a straight track or a curved track, it can operate flexibly. In complex industrial plants or logistics warehouses and other environments, it can effectively handle lifting tasks with various track orientations.

⑤Efficient operation: Its operation process is relatively simple and can quickly complete the loading, lifting, and unloading processes of goods. This reduces the time for each lifting operation and improves the overall work efficiency, helping to enhance the production and logistics efficiency of enterprises.

⑥Good stability: The structural design of the C-type spreader is scientific and reasonable. It is made of high-strength materials and is structurally stable during the lifting process and will not be easily deformed.

Application

Steel mill: In the steel production process, there are a large number of steel coils that need to be transported and stored. The C-type spreader can lift steel coils of various specifications safely and efficiently.

Machinery processing factory: It is used to lift large mechanical parts such as large gears, transmission shafts, and machine tool beds. It is convenient for operations such as transportation, installation, or debugging in the workshop.

Automobile manufacturing plant: On the automobile production line, some large body structural parts, engine assemblies and other components need to be transferred between different workstations during the production process. The C-type spreader can be customized according to the shape and weight of the components to ensure the safety and efficiency of the lifting process and improve production efficiency.

Warehousing and logistics field: In large warehouses, the storage and transportation of goods are important contents of daily work. The C-type spreader can be used to lift various goods such as bundled steel, wood, plastic pipes, etc.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: generally 15 workdays.

2.Production Lead-times: 30-60 workdays after getting your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

We'll show you the photos of the products and packages before you pay the balance.

Q4: What is your advantages?

1. Manufacturer,the most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

4. Rich stock and quick delivery.

Q5. If you can’t find the product on our website,what do you next?

Please send us inquiry with product pictures and drawings by email or other ways and we'll check.