Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

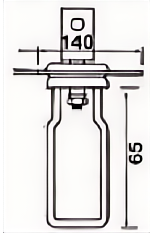

Bearing gear spreader

Product description

When the chain is running, the gear is used with the rack fixed at a specific position. The interaction between them generates and transfers a force, making the suspended workpiece rotate continuously. It is suitable for connection with a single pendant chain.

Structural Features:

①Main structure

Equipped with an advanced bearing rotation system for flexible rotation during lifting. Based on high - precision bearing design, it ensures smooth and accurate rotation, reducing shaking and deviation.

The main body is made of high strength alloy steel with excellent tensile and yield strength, no deformation or fracture in long term use.The alloy material is specially treated for improved toughness and corrosion resistance, adapting to the conveyor line environment.

②Connection parts

At the end of the spreader, professional level connection components are equipped. Usually, standard sized lifting rings or shackles of high strength alloy steel are used for close and safe connection to the crane's hook. The connection part is finely processed with a smooth surface, reducing friction during connection and lifting.

Material characteristics:

The main body uses high strength alloy steel with excellent tensile and yield strength. The specially treated alloy has good toughness, enabling the spreader to absorb and disperse energy during lifting, avoiding damage. Given the possible chemical substances in the conveyor line environment, the material has good corrosion resistance, preventing surface corrosion and performance/servicelife impact.

Working Principle:

When the bearing rotating spreader is connected to the workpiece and subjected to the upward pulling force of the crane, it can evenly transmit the force to each connection point of the workpiece. At the same time, the bearing rotating system will make the workpiece rotate while being lifted according to the external force and its own rotation mechanism.

In the conveyor line, the bearing rotating spreader needs to work according to specific procedures and rhythms. When the control system of the conveyor line sends an instruction, the spreader will quickly lift the workpiece to the specified detection station, ensuring the high efficiency and orderliness of the production process.

Advantages

On a complex assembly line, it can rotate workpieces precisely. The flexible rotation improves lifting efficiency and reduces position - adjusting time. The spreader quickly connects and separates from workpieces, reducing prep time and difficulty. It also efficiently lifts according to the conveyor line's rhythm, enhancing overall efficiency.

The spreader suits various - shaped workpieces, providing convenience, reducing the need for different spreaders, and cutting costs.

It adapts well to all conveyor line equipment, whether automated or manual, and can be adjusted to meet production needs.

Application

Automobile conveyor line: In auto - making, parts are transported and assembled. The spreader can lift engines, frames, doors, etc. At engine assembly, it can lift and rotate as needed for easy operation. When lifting frames, it ensures stability and angle adjustment.

Home appliance conveyor line: On lines of fridges, washers, etc., it can lift large parts. For a fridge, it can lift the shell, liner, compressor. When assembling the shell and liner, it rotates the shell for better efficiency and quality. When lifting the compressor, it ensures safety and adjusts the angle.

Mechanical parts conveyor line: In processing, parts of various shapes and sizes are transported. The spreader fits different shapes. On shaft parts lines, it can lift and rotate during processing. For irregular parts, it can also lift and adjust the angle.

FAQ

Q1: Are you trading company or manufacturer?

A: We are a professional manufacturer with advanced production facilities.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: usually within 15workdays.

2.Production Lead-times: 30-60 workdays after receiving your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before shipment.

Photos of products and packages will be provided for your confirmation before you pay the balance.

Q4: What is your advantages?

As a manufacturer, we offer the most competitive prices and ensure high-quality products.

Skilled technical teams provide excellent support.

Customization (OEM/ODM) is welcome.

Sufficient stock for prompt delivery.

Q5. If you can’t find the product on our website,what do you next?

Send us an inquiry with product pictures and detailed descriptions via email or other channels. We'll promptly check and respond.