Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

1.Using involute gear transmission, alloy steel with carbonize&quencher heat treatment, precision level of gear grinding could reach ISO class 5, the profile and axial modification could enhance the bearing capacity ,stability of mesh and low noise.

2.With integral output shaft and bearing support for both sides of planet wheel, realizing higher precision and higher rigidity.

3.Small backlash, the accurate single stage can reach within 3 arcmin as clients’ request.

4. Gyration parts of the input side with dynamic balance treatment can make sure the gearbox running steadily at high speed.

5.It can combined with any servo motor, can be designed for special combination, and easy for mounting. (It can be specially designed to accept any type of servo motor, mounting is convenient)

6. Simple for maintenance, it don’t need to change the oil(grease) during the service life time

Parameter

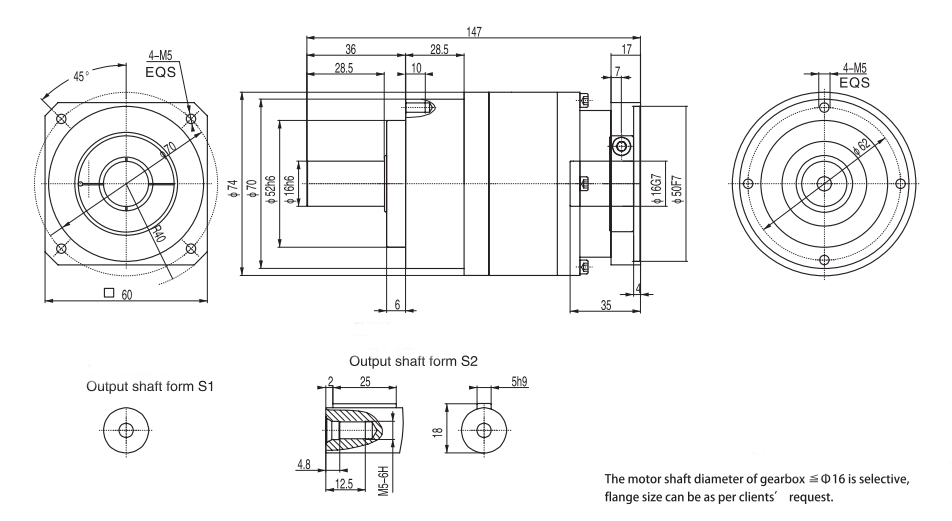

WEP70 Planetary Gearbox Double Stage

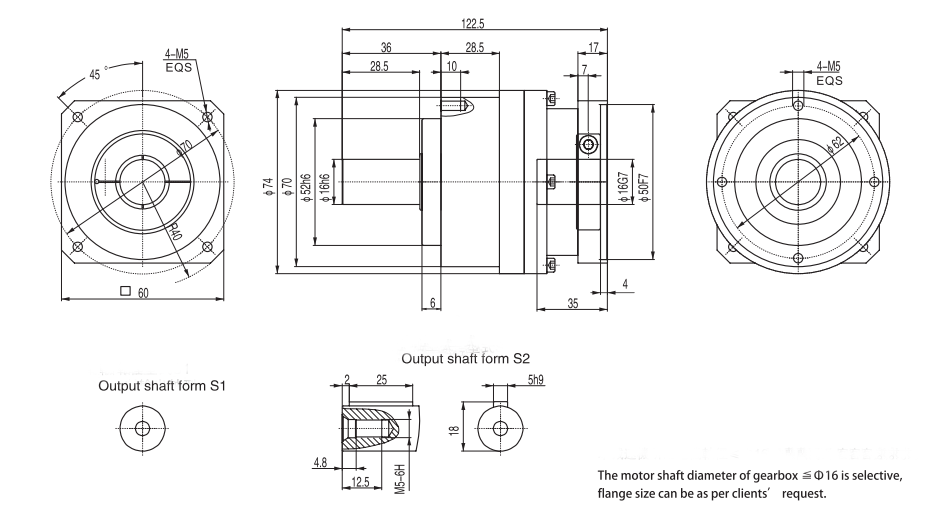

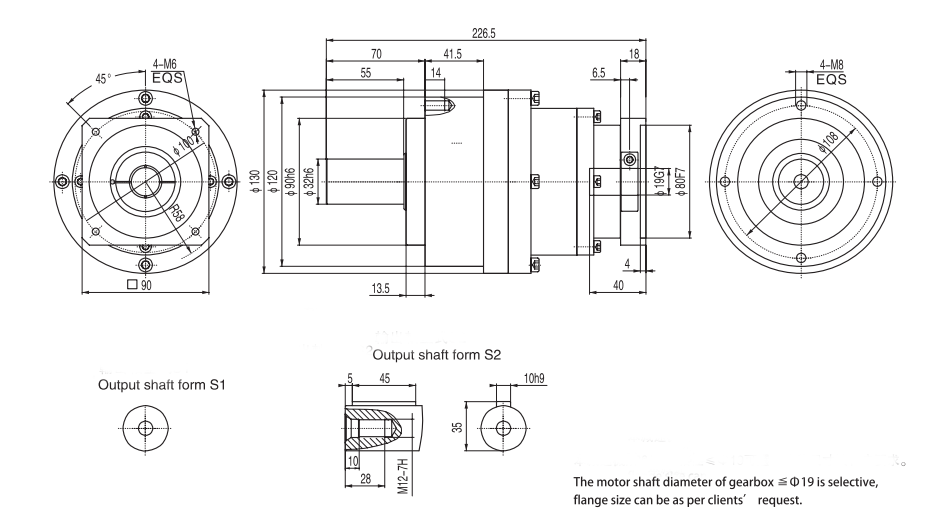

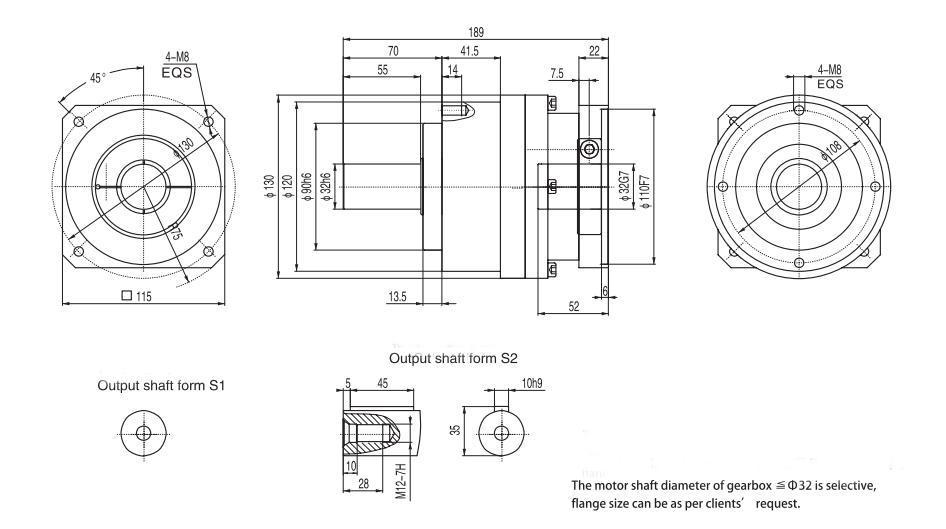

WEP90 Planetary Gearbox Double Stage 图纸

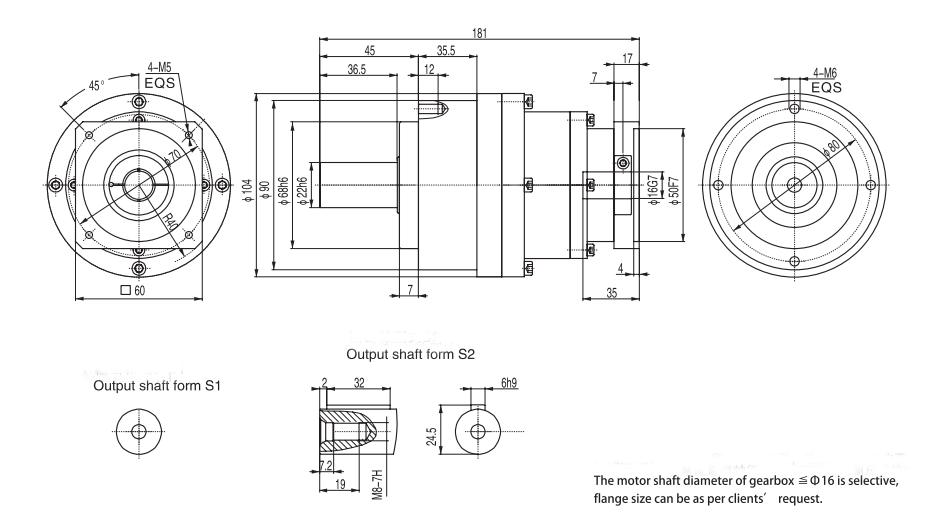

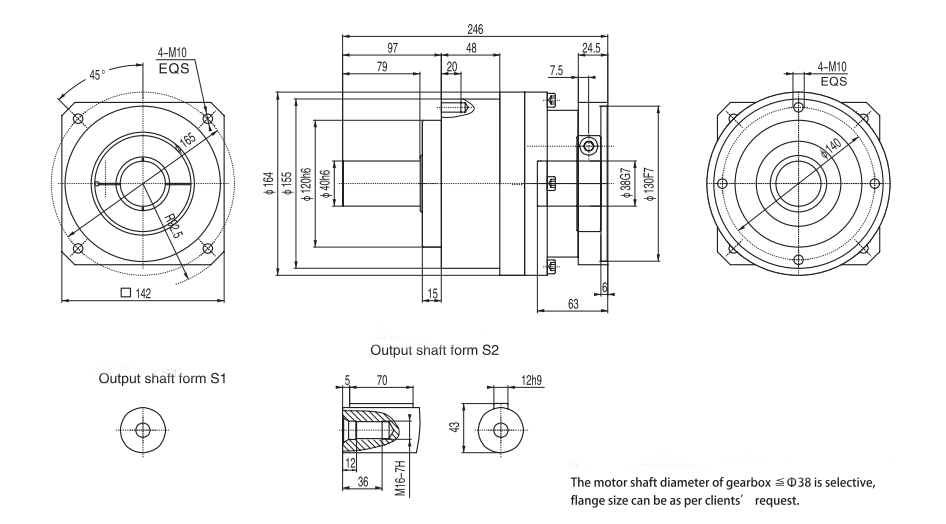

WEP120 Planetary Gearbox Single Stage图纸

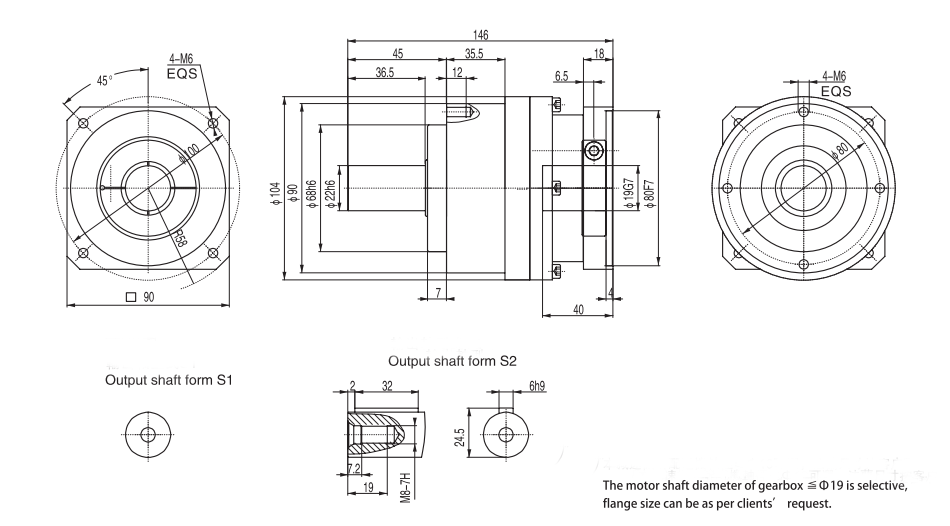

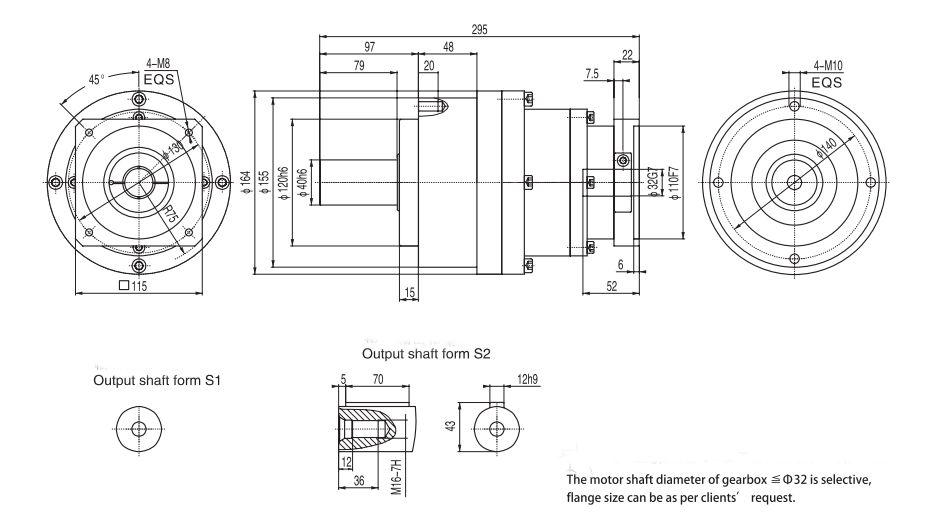

WEP155 Planetary Gearbox Single Stage图纸

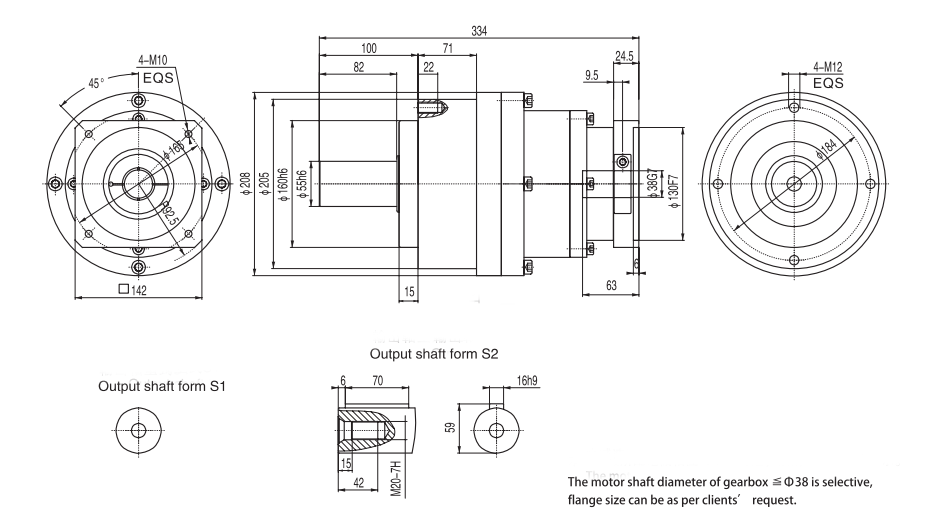

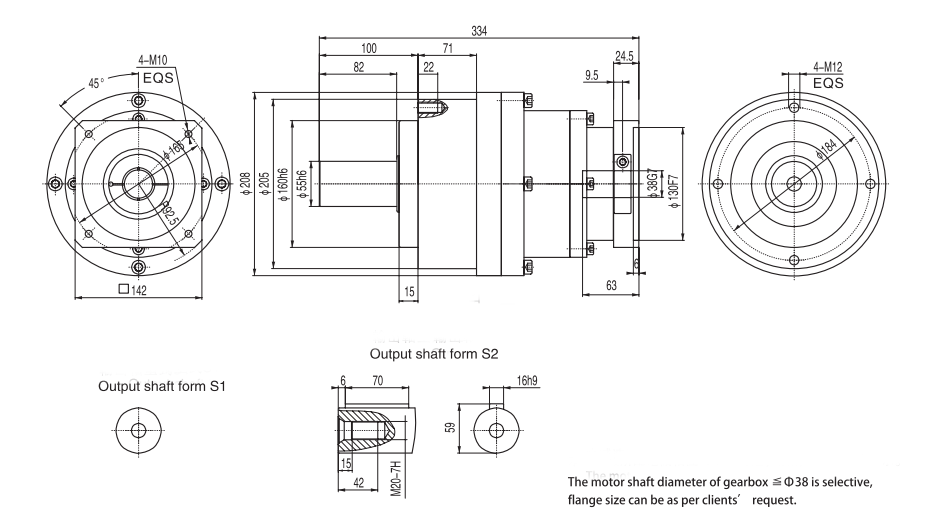

WEP205 Planetary Gearbox Double Stage图纸

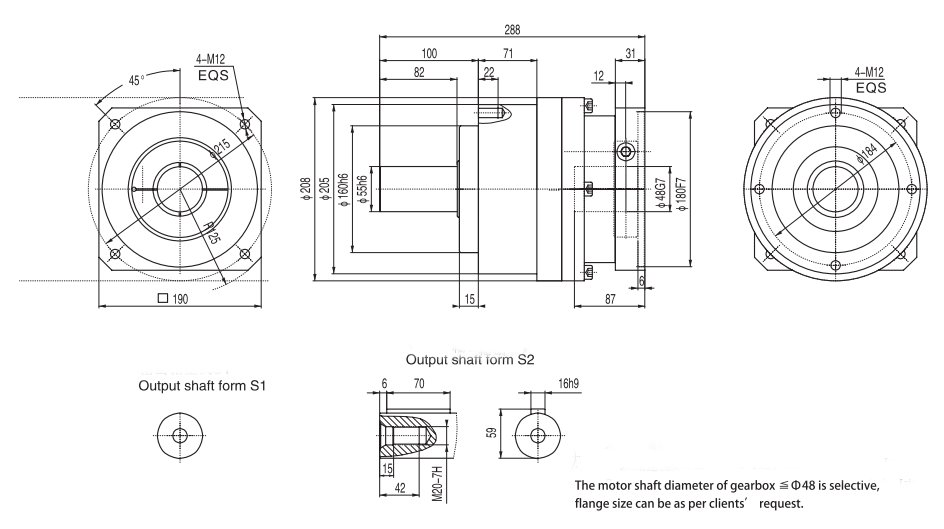

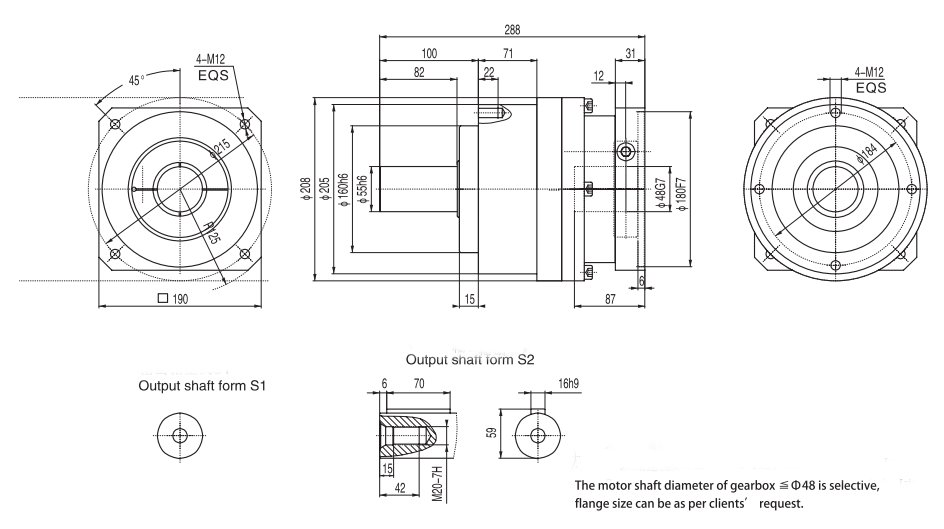

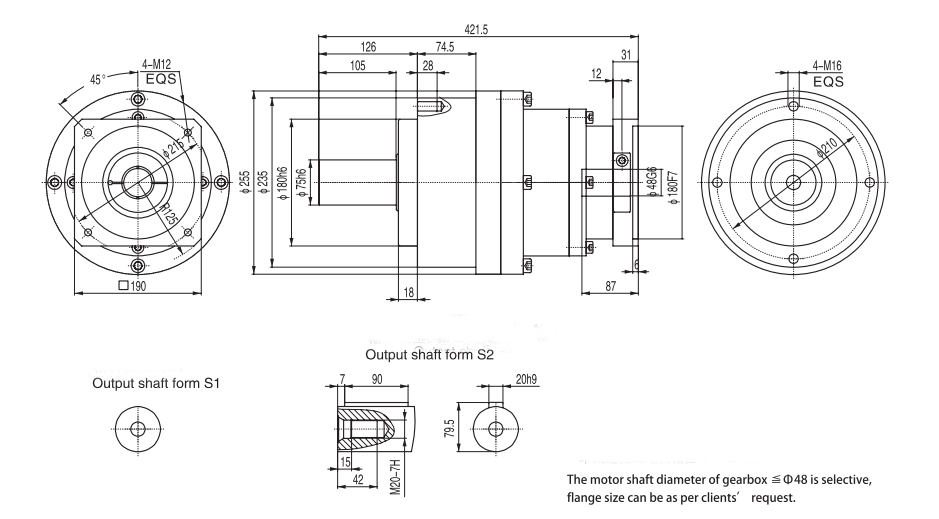

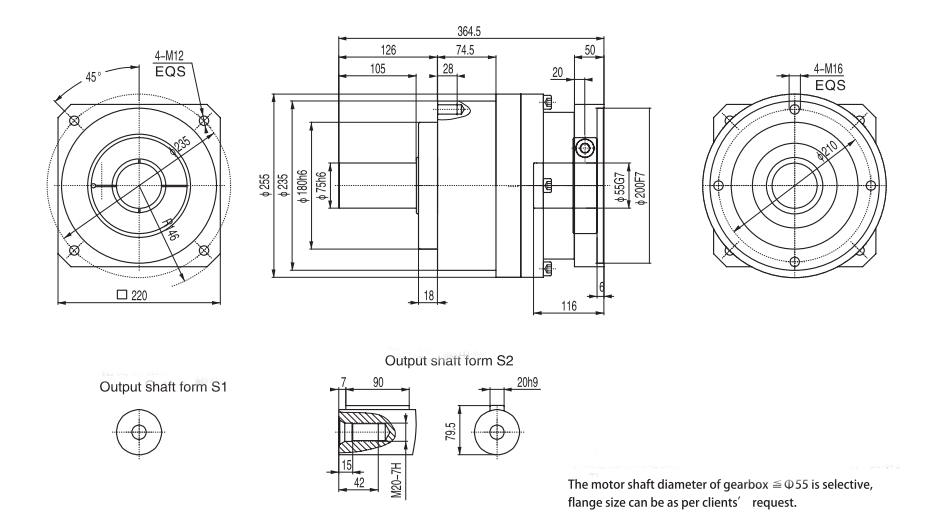

WEP235 Planetary Gearbox Double Stage图纸

WEP235 Planetary Gearbox Double Stage图纸

| TYPE | WEP70 | WEP90 | WEP120 | WEP155 | WEP205 | WEP235 | i | Level | |

| T2N Nominal output torque | Nm | 38 | 118 | 205 | 478 | 929 | 1420 | 3 | 1 |

| 52 | 176 | 310 | 701 | 1288 | 2110 | 4 | |||

| 56 | 185 | 330 | 747 | 1300 | 2180 | 5 | |||

| 52 | 168 | 310 | 696 | 1181 | 2062 | 6 | |||

| 46 | 157 | 278 | 630 | 1162 | 1802 | 7 | |||

| 37 | 125 | 222 | 496 | 920 | 1400 | 8 | |||

| 31 | 104 | 195 | 414 | 774 | 1138 | 9 | |||

| 29 | 98 | 174 | 390 | 720 | 1 080 | 10 | |||

| 38 | 118 | 205 | 478 | 929 | 1420 | 15 | 2 | ||

| 52 | 176 | 310 | 701 | 1288 | 2110 | 20 | |||

| 56 | 185 | 330 | 747 | 1300 | 2180 | 25 | |||

| 52 | 168 | 310 | 696 | 1181 | 2062 | 30 | |||

| 46 | 157 | 278 | 630 | 1162 | 1802 | 35 | |||

| 37 | 125 | 222 | 496 | 920 | 1400 | 40 | |||

| 31 | 104 | 195 | 414 | 774 | 1138 | 45 | |||

| 56 | 185 | 330 | 747 | 1300 | 2180 | 50 | |||

| 52 | 168 | 310 | 696 | 1181 | 2062 | 60 | |||

| 46 | 157 | 278 | 630 | 1162 | 1802 | 70 | |||

| 37 | 125 | 222 | 496 | 920 | 1400 | 80 | |||

| 31 | 104 | 195 | 414 | 774 | 1138 | 90 | |||

| 29 | 98 | 174 | 390 | 720 | 1080 | 100 | |||

| T2NoT1 Emergency Stop Torque | Nm | 3 times Nominal output torque | 3- 100 | 1、2 | |||||

| Torsional rigidity | Nm/aremin | 7 | 15 | 26 | 50 | 150 | 225 | ||

| N1n Nominal input speed | rpm | 3000 | 3000 | 3000 | 3000 | 2000 | 2000 | ||

| n1max Max.input speed | rpm | 6000 | 6000 | 6000 | 6000 | 4000 | 4000 | ||

| F2r2 Max. Radial forces | N | 1320 | 1870 | 4020 | 5730 | 11600 | 18300 | ||

| F2a Max.Axial forces | N | 1450 | 1900 | 3130 | 5110 | 6800 | 10790 | ||

| Precision Backlash | arcmin | 3 | 3 | 3 | 3 | 3 | 3 | 3-10 | 1 |

| 5 | 5 | 5 | 5 | 5 | 5 | 15-100 | 2 | ||

| Standard Backlash | arcmin | 8 | 8 | 8 | 8 | 8 | 8 | 3-10 | 1 |

| 10 | 10 | 10 | 10 | 10 | 10 | 15-100 | 2 | ||

| Full load efficiency | % | 97 | 3-10 | 1 | |||||

| 94 | 15-100 | 2 | |||||||

| Service life | h | 20000 | 3-100 | 1, 2 | |||||

| Weight | kg | 1.7 | 3.4 | 7.2 | 13.2 | 32 | 53 | 3-10 | 1 |

| 2.3 | 4.7 | 9.9 | 17.6 | 36.5 | 66 | 15-100 | 2 | ||

| (n1=3000rpm)Running noise | dB(A) | 55 | 60 | 63 | 65 | 67 | 70 | 3-100 | 1、2 |

| Moment of Inertia | kg.cm2 | 0.407 | 1.479 | 7.182 | 19.30 | 55.55 | 146.3 | 3 | 1 |

| 0.296 | 0.803 | 4. .888 | 11.64 | 37.27 | 97.08 | 4 | |||

| 0.265 | 0.643 | 4.332 | 9.308 | 32.56 | 83,71 | 5 | |||

| 0.251 | 0.557 | 4.036 | 8.429 | 29.99 | 76.00 | 6 | |||

| 0.244 | 0.520 | 3.916 | 7.852 | 28,85 | 72.61 | 7 | |||

| 0.236 | 0.485 | 3.774 | 7.395 | 27,85 | 70.27 | 8 | |||

| 0.232 | 0.469 | 3.717 | 7.153 | 27.24 | 67.97 | 9 | |||

| 0.229 | 0.489 | 3.684 | 7.015 | 26.96 | 67.44 | 10 | |||

| 0.342 | 0.379 | 1. .431 | 7.113 | 16.79 | 53.04 | 15 | 2 | ||

| 0.276 | 0.292 | 0.964 | 5.561 | 11,45 | 42.82 | 20 | |||

| 0.265 | 0.275 | 0.887 | 5.244 | 10.71 | 40.80 | 25 | |||

| 0.263 | 0.270 | 0.853 | 5.169 | 10.34 | 40.00 | 30 | |||

| 0.262 | 0.267 | 0.838 | 5.121 | 10.12 | 39.72 | 35 | |||

| 0.259 | 0.263 | 0.827 | 5.054 | 10.02 | 39.52 | 40 | |||

| 0.258 | 0.261 | 0.825 | 5.036 | 9.957 | 39.39 | 45 | |||

| 0.236 | 0.238 | 0.674 | 4.619 | 8.566 | 35.05 | 50 | |||

| 0.235 | 0.236 | 0,651 | 4.571 | 8.285 | 34, 48 | 60 | |||

| 0.234 | 3.235 | 0.640 | 4.540 | 8.115 | 34.32 | 70 | |||

| 0.231 | 0.232 | 0.634 | 4.488 | 8.042 | 34.20 | 80 | |||

| 0.230 | 0.231 | 0.634 | 4.478 | 8.005 | 34.14 | 90 | |||

| 0.229 | 0.229 | 0.640 | 4,473 | 7,991 | 34.12 | 100 | |||

| 1.The Max Acceleration Torque T2B=60%. T2NOT 2.Applied to the output shaft center at 100 rpm. 3. For continuous operation,the service life time is less than 10,000 hours. | |||||||||

Catalogue