Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

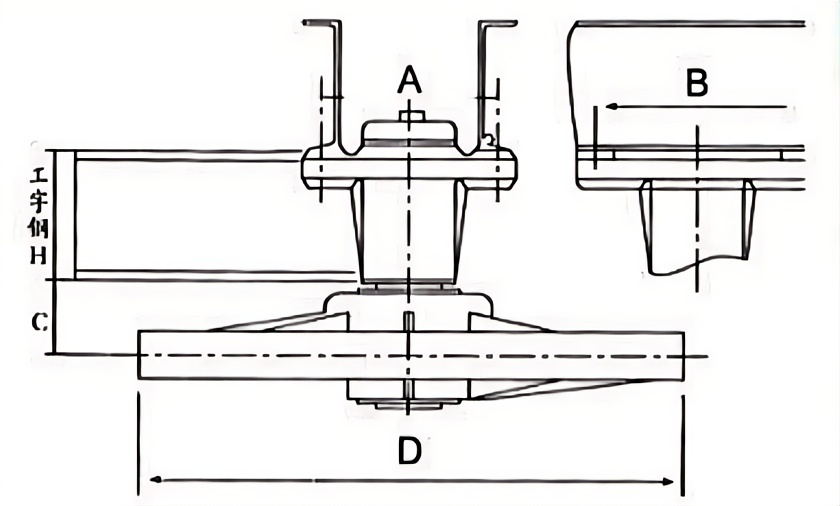

Sprocket return idler horizontal curve

Product description

The rotating wheel of the sprocket rotating device is a sprocket, which is generally used for small turning radius. It is recommended to use a sprocket with Z=10.(Z-number of sprocket teeth)

Product Specification

| A | B | Turning radius(R) | D | C |

XT80 | 180 | 250 | 305 | φ580 | 63.5 |

XT100 | 180 | 250 | 317 | φ606 | 822 |

XT160 | 200 | 350 | 404 | φ770 | 102 |

Performance characteristics:

High Efficiency: The transmission efficiency is typically between 92% and 98%.

Strong Adaptability:Capable of operating in harsh environments with less stringent installation precision requirements.

High Load-bearing Capacity: Suitable for heavy load and low-speed transmission.

Compact Structure: Takes up minimal space.

Noise and Vibration: There is some noise and impact during operation, but the transmission is relatively smooth.

Wide Application: Used in various industrial fields, especially where reliable transmission and a significant distance between two shafts are required.

Application

Industrial Machinery: In various industrial production lines, chain-driven rotation devices are used to drive conveyors, elevators, packaging machinery, and more.

Agricultural Machinery: In the agricultural sector, chain-driven rotation devices are commonly used in harvesters, seeders, and other agricultural automation equipment.

Construction Machinery: On construction sites, chain-driven rotation devices may be used in cranes, elevators, and other heavy-duty equipment transmission systems.

Material Handling: In logistics and warehousing systems, chain-driven rotation devices are used to power forklifts, conveyor systems, and lifting platforms.

Automotive Industry: In car manufacturing, chain-driven rotation devices are used in assembly lines and testing equipment.

How does it work

Drive by the driving sprocket: The chain loop starts moving when the driving sprocket, usually powered by an electric motor or other power source, rotates.

Engagement of chain and sprocket teeth: The teeth on the sprockets mesh with the chain links, causing the chain to move as the sprocket turns.

Continuous chain movement: As the driving sprocket rotates, the tight side of the chain is pulled, and the slack side loosens, transferring power from the driving sprocket to the driven sprocket.

Rotation of the driven sprocket: The chain engages with the teeth of the driven sprocket, causing it to turn and thus transferring motion to the connected machinery.

Tensioning device: To maintain proper tension and prevent slack or excessive tightness, a tensioning device is used to adjust the chain's tightness.

Structural parameter

Sprocket Diameter: The diameter of the sprocket, which determines the tension of the chain and the transmission ratio.

Number of Teeth: The number of teeth on the sprocket, affecting the transmission ratio and load capacity.

Chain Pitch: The distance between the centers of adjacent pins on the chain, affecting the strength and size of the chain.

Chain Width: The width of the chain, affecting the load capacity and stability of the chain.

Chain Material: The material of the chain, such as carbon steel, stainless steel, etc., affecting the strength and corrosion resistance of the chain.

Center Distance: The distance between the centers of two sprockets, affecting the tension of the chain and transmission efficiency.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: generally 15 workdays.

2.Production Lead-times:30-60 workdays after getting your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

We'll show you the photos of the products and packages before you pay the balance.

Q4: What is your advantages?

1. Manufacturer,the most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

4. Rich stock and quick delivery.

Q5. If you can’t find the product on our website,what do you next?

Please send us inquiry with product pictures and drawings by email or other ways and we'll check.