Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

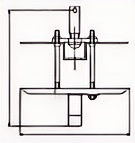

Cross disc spreader

Product description

The structure of the cross disc spreader is similar to the traditional cross spreader in main framework and key components. An additional disc made of special anti - oil and corrosion - resistant material is added above the hook. It's carefully designed and positioned to catch possible oil dripping in the track, preventing the workpiece from being contaminated and ensuring its quality and cleanliness during handling.

Structural Features:

Cross structure foundation: With an overall cross shaped structure, this design keeps the spreader stable during suspension and lifting, preventing the workpiece from swaying or tilting easily. The four directions of the cross provide balanced support, enabling stable lifting of workpieces with irregular shapes or uncertain centers of gravity.

Disc component: There is usually a disc above the cross structure. It has two main functions. One is to increase the contact area with the conveying equipment for better stability during operation. The other is to catch impurities like oil, dust from the track to ensure the workpiece's cleanliness and avoid affecting subsequent processing or use.

Material characteristics:

Generally, high strength steel or alloy materials are used for manufacturing to ensure that the spreader has sufficient strength and rigidity to bear the lifting weight and various stresses during operation. At the same time, the materials also need to have good corrosion resistance and wear resistance to adapt to various harsh conditions in industrial production environments.

Working Principle:

The cross-shaped structure is the key and can evenly bear a load of five tons. High-strength alloy steel and other materials are used to ensure strength and rigidity. It is connected to the lifting equipment through the top connection point to achieve smooth transmission of force. It is connected to the conveying system through a specific mechanism. The conveyor provides energy and guides movement. Some spreaders can rotate to adjust the load direction. The cross-shaped structure and reasonable load connection ensure stable movement. At the same time, anti-sway measures such as installing shock absorbers, controlling speed, and optimizing layout through the connection points are used to prevent load sway during transportation.

Advantages

①High stability: The cross shaped structure allows the spreader to be stable during suspension and lifting. Its four directions provide balanced support, adapting well to workpieces with irregular shapes or uncertain centers of gravity for stable lifting, ensuring no sway or tilt during painting and the uniformity and accuracy of painting.

②Anti-oil drip design: The hook above disc can catch oil stains, dust and other impurities dripping from the conveying track, preventing them from contacting the workpiece, ensuring its cleanliness, avoiding impacts on painting processing and reducing quality problems caused by such impurities.

③Good cooperation with the painting line: The spreader's design matches the painting line's conveying system, enabling easy connection and disconnection with equipment like conveying chains. The simple and quick operation improves the production line's work efficiency.

④Excellent material: Generally made of high strength steel or alloy materials, it has good corrosion and wear resistance, adapting to harsh conditions in industrial production environments like painting workshops.

⑤Low maintenance cost: Thanks to the material's excellent performance and stable structure, the spreader needs less frequent maintenance and repair during use, reducing enterprises' maintenance cost and equipment downtime and improving production efficiency.