Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

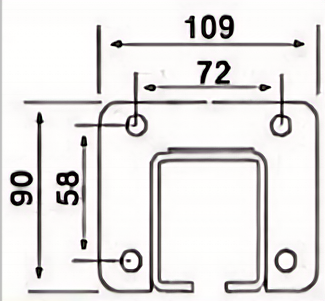

Flange plate

Product description

It is used for interconnecting two tracks to facilitate construction and maintenance. Use M10×20 bolt.

Structural Features:

①Shape and Size

Flange is generally circular, and its outer diameter and inner diameter sizes vary according to different application scenarios and pipeline specifications. The common outer diameter range varies from several centimeters to several meters, and the inner diameter matches the inner diameter of the connected pipeline.

The thickness of the flange also varies due to different bearing pressures and usage environments, generally ranging from several millimeters to several tens of millimeters.

②Distribution of Connection Holes

The holes for connecting bolts are evenly distributed on the flange. The number, diameter, and spacing of these holes usually follow certain standard specifications, such as international standards (ISO), national standards (such as GB/T standards), and industry-specific standards. Common numbers of bolt holes include 4, 8, 12, etc.

Material characteristics:

Carbon steel flanges are the most common type. They have good strength and toughness and are suitable for general industrial pipeline systems and medium-pressure environments. Their costs are relatively low, so they are widely used.

Stainless steel flanges have excellent corrosion resistance and are suitable for industries with high requirements for hygiene and corrosion resistance, such as the chemical, food, and pharmaceutical industries. Common stainless steel materials include 304, 304L, 316, and 316L.

Alloy steel flanges are used for pipeline connections in high-pressure, high-temperature, and special environments. They have higher strength and heat resistance and can withstand greater stress and temperature changes.

Working Principle:

When two flanges are tightened with bolts, the sealing gasket in the middle will be squeezed and deformed, filling the tiny gaps between the two sealing surfaces, thus preventing the leakage of the medium.

The connection method of flanges makes the pipeline system have a certain degree of maintainability and expandability. When it is necessary to repair or replace pipeline components, the flange connection can be easily disassembled without causing too much damage to the entire pipeline system.

Advantages

①Good sealing performance

With appropriate sealing surface forms and high-quality sealing gaskets, flange pieces can achieve good sealing effects under various pressure and temperature conditions, preventing medium leakage and ensuring the safe operation of the system.

②Firm and reliable connection

Through bolt connections, flange pieces can firmly connect pipes and equipment together, withstand certain external forces and vibrations, and ensure the stability and durability of the connection.

③High universality

Flange pieces that follow standard specifications have high universality and can be matched and connected with pipes and equipment produced by different manufacturers, facilitating the integration and maintenance of the system.

④Easy to install and maintain

The installation process of flange pieces is relatively simple. Just align the two flange pieces, insert the sealing gasket, and then tighten the bolts. During maintenance, relevant parts can also be easily disassembled and replaced.

Application

Connect the driving device and the main structure of the conveyor line to ensure the stable transmission of power and facilitate the disassembly, assembly and maintenance of the driving device.

It is used for splicing different sections of the track to ensure continuity and flatness. It can also connect special track sections at turning and other parts to achieve turning.

Connect the tensioning device and the main structure to make the tensioning device work effectively and be convenient for adjustment and maintenance.

Connect the spreader, hanger and the conveyor chain or track to ensure their firm installation, prevent the falling of objects, and can be adjusted as required.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: generally 15 workdays.

2.Production Lead-times: 30-60 workdays after getting your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

We'll show you the photos of the products and packages before you pay the balance.

Q4: What is your advantages?

1. Manufacturer,the most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

4. Rich stock and quick delivery.

Q5. If you can’t find the product on our website,what do you next?

Please send us inquiry with product pictures and drawings by email or other ways and we'll check.