Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

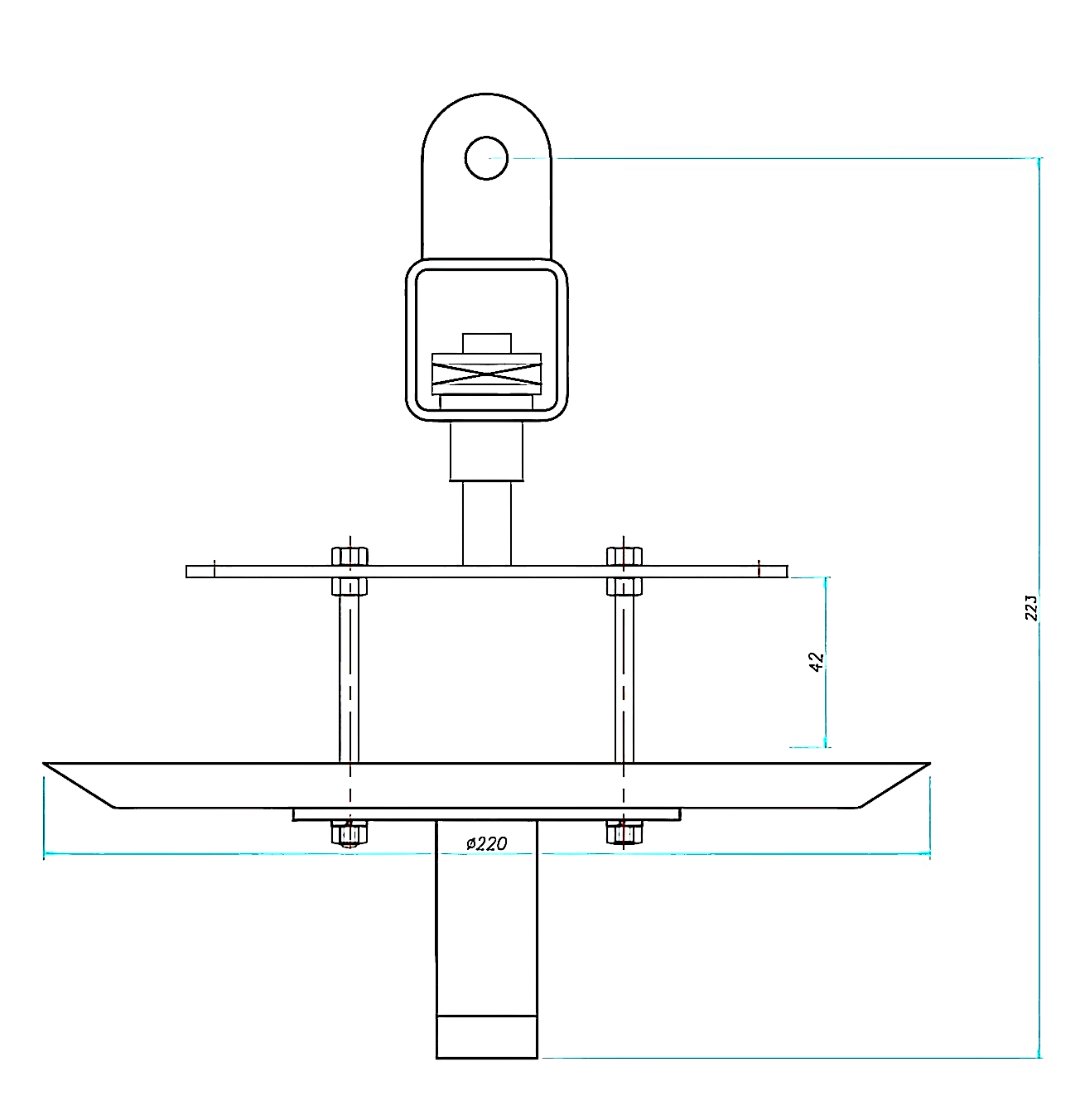

Gear disc conveyor spreader

Product description

When the chain operates and moves smoothly, the gear works in conjunction with the rack that is firmly fixed at a specific position. This combination enables the suspended workpiece to rotate continuously in a stable and controlled manner. The gear meshes precisely with the rack, ensuring a seamless interaction that allows for the smooth rotation of the workpiece. This setup is designed to enhance the efficiency and effectiveness of the production process, providing a reliable means of achieving continuous rotation for the suspended workpiece.

Structural Features:

The gear disc spreader is designed with precision and innovation. It has a sturdy disc made of high-quality materials for durability and stability. The integrated gear system is precisely engineered to mesh smoothly. Gears are of hardened materials for heavy loads and continuous operation. The design enables easy connection and disconnection to the lifting device. The disc has a smooth surface to prevent damage to workpieces. Additionally, it may have adjustable components for different workpieces and safety mechanisms for secure lifting and to prevent accidental detachment.

Material characteristics:

The gear disc spreader is usually made of high-strength alloy steel. Alloy steel has excellent strength and durability, can withstand heavy loads and continuous use. It has high tensile strength for structural stability even in extreme conditions. The material is resistant to wear and corrosion, prolonging the spreader's service life. Some may have special coatings or surface treatments to enhance abrasion and corrosion resistance. Material choice is crucial for the spreader's reliability and safety in industrial applications.

Working Principle:

The gear disc spreader is composed of a disc and a gear transmission system. After being connected to the lifting equipment, it is lifted by the lifting equipment. During operation, the gear on the disc interacts with transmission components such as racks fixed at specific positions. When the lifting equipment moves or operates, the gear transmission makes the disc rotate and drives the suspended workpiece to rotate. The rotation speed and angle of the workpiece are controlled by the gear transmission ratio to meet different work requirements. Its structural design ensures stability and safety during rotation and lifting.

Advantages

Efficient rotation function:During operation, the gear interacts with transmission components at specific positions, enabling the suspended workpiece to rotate continuously. This meets the needs of specific processing techniques like spraying and electroplating, improving production efficiency and quality. In scenarios requiring multi-angle operation or assembly, the gear disc spreader can adjust the workpiece's angle conveniently, making operations more efficient.

Precise positioning and control:

The gear transmission ratio can precisely control the rotation speed and angle of the workpiece, meeting high-precision requirements for workpiece position and posture and ensuring processing or assembly accuracy. For some jobs with specific operation orders or directions, the gear disc spreader provides stable and predictable rotation and positioning, enhancing production consistency.

Strong applicability:

It can be applied to the lifting of various types, sizes and shapes of workpieces. Especially for disc-shaped or similar-shaped workpieces, such as gears and disc parts, it has good adaptability.

Stable and reliable structure:

The overall structure design is usually more reasonable, with good stability and load-bearing capacity. It can safely lift heavier workpieces and ensure the safety of the production process. The gear transmission system has high reliability, small wear and long service life. It can maintain stable performance during long-term use, reducing the frequency of maintenance and replacement and lowering the use cost.

Application

Machining: In mechanical part production, gears and disc-shaped parts are lifted and transferred. For example, in axle assembly, the driven bevel gear can use a gear disc spreader for handling between processes, being convenient and avoiding damage.

Metal processing: In metal production lines like steel mills and non-ferrous metal plants, it lifts and transfers metal discs, gear-shaped blanks, semi-finished and finished products between equipment or workstations to improve efficiency.

Mold manufacturing: Molds are heavy and have special shapes. The gear disc spreader can lift various molds safely, including disc-shaped parts, facilitating installation, debugging and storage.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: generally 15 workdays.

2.Production Lead-times: 30-60 workdays after getting your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

We'll show you the photos of the products and packages before you pay the balance.

Q4: What is your advantages?

1. Manufacturer,the most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

4. Rich stock and quick delivery.

Q5. If you can’t find the product on our website,what do you next?

Please send us inquiry with product pictures and drawings by email or other ways and we'll check.