Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

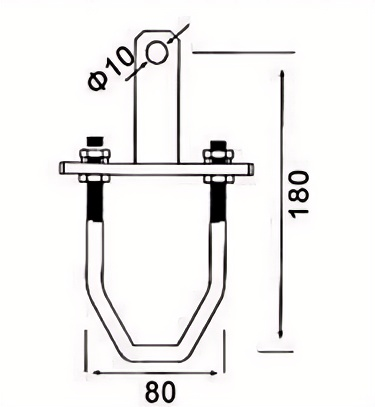

Plating conveyor spreader

Product description

This spreader has been meticulously designed with precision for electroplating factories.It is the result of extensive research and engineering expertise. The design takes into account the unique requirements of electroplating environments and ensures durability, reliability, and optimal performance.

Structural Features:

Strength and rigidity:Plating spreaders have sufficient strength and rigidity and can safely carry electroplated workpieces of various weights. Their structure is carefully designed to be able to withstand the tensile force and gravity during the lifting process and ensure the safety of operation.

Diversified shapes and sizes: According to the needs of different electroplated workpieces, the shapes and sizes of electroplating spreaders are diverse. There are precision spreaders suitable for small workpieces and heavy-duty spreaders that can carry large workpieces, meeting the needs of different production scenarios.

Material characteristics:

Plating spreaders are usually made of corrosion-resistant materials such as stainless steel and titanium alloy. These materials can resist the erosion of corrosive chemical substances such as acids, alkalis, and salts during the electroplating process, ensuring that the spreader has a long service life in the harsh electroplating environment.

Working Principle:

Plating spreaders are designed to hold and suspend electroplated workpieces during the plating process. They are usually connected to a lifting device. When in use, the spreader is attached to the workpiece firmly. Then, the lifting device lifts the spreader and workpiece and immerses them into the electroplating bath. The electrical current is passed through the bath and the workpiece, causing a chemical reaction that deposits a layer of metal on the surface of the workpiece. The spreader ensures that the workpiece is held in a stable position during the electroplating process to achieve uniform plating. After electroplating is completed, the lifting device lifts the spreader and workpiece out of the bath.

Advantages

Corrosion resistance:Made of materials such as stainless steel and titanium alloy, they can withstand the erosion of corrosive substances in the electroplating environment, ensuring a long service life.

Stable structure:They have sufficient strength and rigidity to safely carry various electroplated workpieces. The carefully designed structure can ensure the stability of the workpiece during the lifting and electroplating process.

Diverse shapes and sizes:Plating spreaders can be customized according to different workpiece requirements, meeting the needs of different production scenarios.

Easy to operate:The design is user-friendly, enabling quick and accurate placement and removal of workpieces, improving production efficiency.

Application

In industrial environments, they are usually used for lifting and moving heavy mechanical parts, steel structures, and large equipment. For example, in manufacturing plants, single-point slings can be used to lift engines, transmissions, and other large components for assembly or repair.

On construction sites, they are used for lifting building materials such as steel beams, precast concrete panels, and large-diameter pipes. Single-point slings can also be used to move construction equipment and tools.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: generally 15 workdays.

2.Production Lead-times: 30-60 workdays after getting your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

We'll show you the photos of the products and packages before you pay the balance.

Q4: What is your advantages?

1. Manufacturer,the most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

4. Rich stock and quick delivery.

Q5. If you can’t find the product on our website,what do you next?

Please send us inquiry with product pictures and drawings by email or other ways and we'll check.