Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

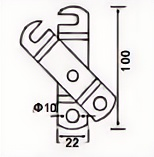

Single point spreader

Product description

It is directly and firmly connected to the chain, presenting the remarkable characteristics of extremely convenient and rapid installation. This not only simplifies the installation process but also saves valuable time and effort. Its lower end is frequently connected to a cross spreader or a cross disc spreader, enabling seamless integration and efficient operation in various applications. The combination of these elements offers enhanced functionality and versatility, making it an ideal choice for a wide range of industrial and mechanical settings.

Structural Features:

1. Compact Design:The single-point sling has a relatively simple and compact structure. It consists of a main hook or connection point that serves as the single attachment point for lifting. This design makes it easy to handle and store, occupying minimal space.

2. High-strength Materials:It is typically made of high-strength materials such as alloy steel. These materials ensure that the sling can withstand heavy loads and provide excellent durability and reliability. The choice of materials also contributes to the sling's resistance to wear, corrosion, and fatigue.

3. Robust Hook or Connector:The hook or connector at the single-point is designed to be extremely strong and secure. It is engineered to firmly grip the load and prevent accidental detachment during lifting operations. The hook often features a safety latch or locking mechanism to enhance safety.

4. Load Distribution:Although it is a single-point attachment, the sling is designed to distribute the load evenly across its structure. This helps to prevent excessive stress on any one particular area and ensures stable lifting and transportation of the load.

Working Principle

The sling is designed to distribute the load evenly across its structure to ensure stability and safety during lifting. The high-strength materials used in the sling are capable of withstanding the weight of the load and the forces generated during the lifting process.

The hook or connector at the single-point is engineered to grip the load firmly and prevent accidental detachment. Safety features such as latches or locking mechanisms may be incorporated to enhance the security of the connection.

In summary, the single-point sling works by providing a reliable and efficient means of lifting a load through a single attachment point, while ensuring the safety and stability of the lifting operation.

Advantages

Convenient operation:With only one connection point, the single-point sling is easy to operate. Operators can quickly connect it to heavy objects and lift and move them via lifting equipment. Moreover, it's lightweight and easy to carry and handle.

Strong versatility:The single-point sling is applicable to various heavy objects and lifting equipment. It can also be customized and modified according to different needs to enhance its versatility and applicability.

Safe and reliable:In design and manufacturing, safety is a priority. High-strength materials and reliable connections ensure its safety during use. Equipped with safety devices like safety locks and overload protection, it's even more secure.

Space-saving:Due to its simple structure, the single-point sling occupies little space. In places with limited space like factory workshops and warehouses, it can better display its advantages and improve work efficiency.

Application

In industrial environments, they are usually used for lifting and moving heavy mechanical parts, steel structures, and large equipment. For example, in manufacturing plants, single-point slings can be used to lift engines, transmissions, and other large components for assembly or repair.

On construction sites, they are used for lifting building materials such as steel beams, precast concrete panels, and large-diameter pipes. Single-point slings can also be used to move construction equipment and tools.

Precautions for using Single point spreader

①Select the appropriate spreader: According to the weight, shape, and size of the lifted object, choose the single-shaped spreader of the appropriate specification and model. Ensure that the carrying capacity of the spreader is greater than the weight of the object to avoid overloading.

②Check the integrity of the spreader: Before use, carefully inspect each component of the single-shaped spreader, including the hook, ring, and rigging, to ensure there are no damages, deformations, cracks, or other defects. If there are any issues, replace or repair it in time.

③Correctly connect to the heavy object: Firmly connect the hook or connection point of the single-shaped spreader to the heavy object to ensure a reliable connection. For irregularly shaped heavy objects, auxiliary rigging or spreaders can be used for fixation to prevent the heavy object from tilting or slipping during lifting.

④Follow operating procedures: Strictly follow the operating procedures of lifting equipment and the usage instructions of the single-shaped spreader. Avoid illegal operations such as rapid lifting, sudden stops, and oblique pulling to prevent damage to the spreader and heavy object.

⑤Pay attention to the lifting environment: During lifting, pay attention to the surrounding environment to avoid collisions with other objects. At the same time, ensure that there is sufficient lifting space to avoid interference between the spreader and heavy object and obstacles.

⑥Regular inspection and maintenance: Conduct regular inspections and maintenance on the single-shaped spreader, including cleaning, lubrication, and tightening. Timely discover and handle problems such as wear, corrosion, and deformation of the spreader to ensure its performance and safety.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: generally 15 workdays.

2.Production Lead-times: 30-60 workdays after getting your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

We'll show you the photos of the products and packages before you pay the balance.

Q4: What is your advantages?

1. Manufacturer,the most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

4. Rich stock and quick delivery.

Q5. If you can’t find the product on our website,what do you next?

Please send us inquiry with product pictures and drawings by email or other ways and we'll check.