Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

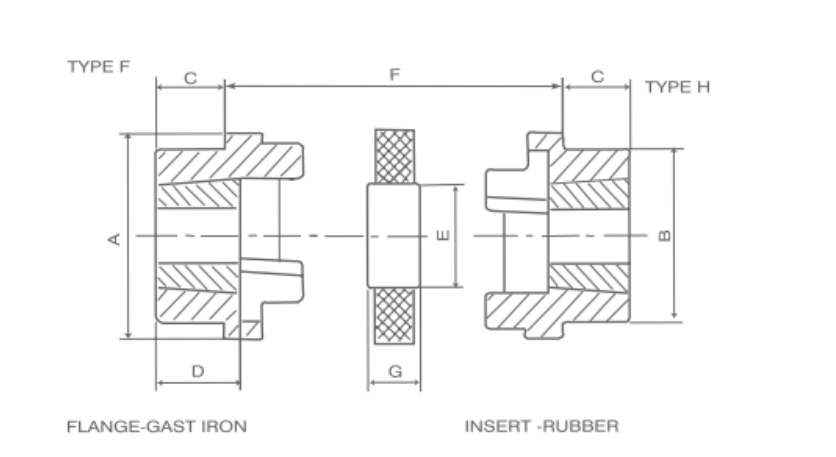

Taper Bore Couplings is one kind of coupling that is widely used. It's simple to construct, is safe and reliable to use and easy and quick installation with no extra tools needed.All you need is a hexagon wrench.

There is little to no maintenance or lubrication is required.Taper bore coupling are made of GG25 high grade cast iron with black phosphate. The strength will ensure safe running under the rated conditions.

parameter

HRC Taper bore universal series

| Size | Bush | A | B | E | F | G | C | D | J | Max bore | L | Maximum misalignment | Max Revolution n(rpm) | Moment of inertia (kg.cm²) | G (Kg) | ||

| mm | nch | Parallel | Axia | ||||||||||||||

| 70 90 110 130 150 | 1008 1108 1610 1610 2012 | 69 85 112 130 150 | 60 70 100 105 115 | 31 32 45 50 60 | 25 30.5 45 53 60 | 18 22.5 29 36 40 | 20 19.5 18.5 18 23.5 | 23.5 23.5 26.5 26.5 33.5 | 29 29 38 38 42 | 25 28 42 42 50 | 1 11/8 15/8 15/8 2 | 65 69.5 82 89 107 | 0.3 0.3 0.3 0.4 0.4 | +0.2 +0.5 +0.6 +0.8 +0.9 | 9100 7400 5630 4850 4200 | 8.5 11.5 40 78 181 | 1.00 1.17 5.00 5.46 7.11 |

| 180 230 280 | 2517 3020 3525 | 180 225 275 | 125 155 206 | 77 99 119 | 73 85.5 106 | 49 59.5 74.5 | 34.5 39.5 51 | 46.5 52.5 66.5 | 48 55 67 | 60 75 100 | 3 4 | 142 165 208 | 0.4 0.5 0.5 | +1.1 +1.3 +1.7 | 3500 2800 2300 | 434 1207 4465 | 16.60 26.00 50.00 |

| J-the wrench clearance rquired for tightening and loosening the bush on the shaft. | |||||||||||||||||

| L=2C+f | |||||||||||||||||

Taper bore HRC flexible couplings

| Power ratings(KW) | ||||||||

| Speed rev/min | Coupling Size | |||||||

| 70 | 90 | 110 | 130 | 150 | 180 | 230 | 280 | |

| 100 200 400 600 720 | 0.33 0.66 1.32 1.98 2.37 | 0.84 1.68 3.35 5.03 6.03 | 1.68 3.35 6.70 10.1 12.1 | 3.30 6.60 13.2 19.8 23.8 | 6.28 12.6 25.1 37.7 45.2 | 9.95 19.9 39.8 59.7 71.6 | 20.9 41.9 83.8 126 151 | 33.0 65.0 132 198 238 |

| 800 960 1200 1440 1600 | 2.64 3.17 3.96 4.75 5.28 | 6.70 8.04 10.1 12.1 13.4 | 13.4 16.1 20.1 24.1 26.8 | 26.4 31.7 39.6 47.5 52.8 | 50.3 60.3 75.4 90.5 101.0 | 79.6 95.5 119 143 159 | 168 201 251 302 335 | 264 317 396 475 528 |

| 1800 2000 2200 2400 2600 | 5.94 6.60 7.26 7.92 8.58 | 15.1 16.8 18.4 20.1 21.8 | 30.2 33.5 36.9 40.2 43.6 | 59.4 66.0 72.6 79.2 85.8 | 113 126 138 151 163 | 179 199 219 239 259 | 377 419 461 503 545 | 594 660 726 |

| 2880 3000 3600 | 9.50 9.90 11.9 | 24.1 25.1 30.1 | 48.3 50.3 60.3 | 95 99 118 | 181 188 226 | 286 298 | ||

| Nominal Torque(Nm) | 31.5 | 80 | 160 | 315 | 600 | 950 | 2000 | 3150 |

| Max Torgue(Nm) | 72 | 180 | 360 | 720 | 1500 | 2350 | 5000 | 7200 |

catalogue