Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

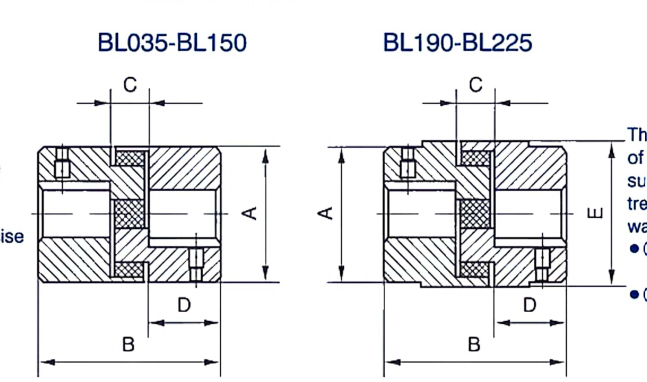

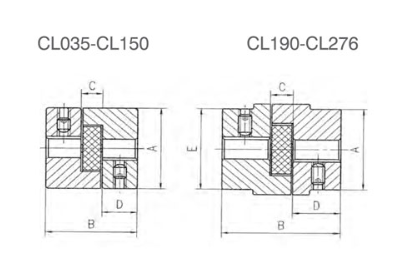

The L-coupling consists of two standard L-hubs and a spider standard L-coupling hub materials include powder metallurgy iron or cast iron.

L-couplings with simple design, easy installation and maintenance, and do not require lubrication.

It is able to accommodate both axial and radial misalignment, ensuring that it will still work in the event of misalignment.

The spider part is made of a variety of materials, such as SOX (NBR) rubber, to meet different application needs and torque requirements

parameter

| Catalog | Dimension | Wt-Lbs | Torque ln.-Lbs | Maximum RPM | Bore | ||||||

| A | B | C | D | E | Min Bore | Max Bore | Min | Max | |||

| BL 035 | 5/8 | 13/16 | 9/32 | 17/64 | - | 0.01 | 0.01 | 3.52 | 31000 | 1/8 | 3/8 |

| BL 050 | 15/64 | 123/32 | 15/32 | 5/8 | - | 0.29 | 0.24 | 25.8 | 18000 | 1/4 | 5/8 |

| BL 070 | 123/64 | 2 | 1/2 | 3/4 | - | 0.59 | 0.54 | 44.1 | 14000 | 1/4 | 3/4 |

| BL 075 | 13/4 | 21/8 | 1/2 | 13/16 | - | 1.00 | 0.86 | 88.2 | 11000 | 1/4 | 7/8 |

| BL 090 | 27/64 | 21/8 | 1/2 | 13/16 | - | 1.48 | 1.32 | 145 | 9000 | 1/4 | 1 |

| BL 095 | 27/64 | 21/2 | 1/2 | 1 | - | 1.75 | 1.52 | 189 | 9000 | 7/16 | 11/8 |

| BL 099 | 217/32 | 27/8 | 3/4 | 11/16 | - | 2.50 | 2.17 | 315 | 7000 | 7/16 | 13/16 |

| BL 100 | 217/32 | 31/2 | 3/4 | 13/8 | - | 3.42 | 2.92 | 415 | 7000 | 7/16 | 13/8 |

| BL 110 | 35/16 | 41/4 | 7/8 | 111/16 | - | 6.45 | 5.61 | 788 | 5000 | 5/8 | 15/8 |

| BL 150 | 33/4 | 41/2 | 1 | 13/4 | - | 8.95 | 7.73 | 1260 | 5000 | 5/8 | 17/8 |

| BL 190 | 4 | 51/4 | 1 | 21/8 | 41/2 | 8.83 | 7.04 | 1702 | 5000 | 3/4 | 21/8 |

| BL 225 | 41/4 | 6 | 1 | 21/2 | 5 | 12.28 | 9.60 | 2332 | 4000 | 3/4 | 23/8 |

| Catalog | Fundamental dimensions | torgue needed nm | rotational speed rpm | Bore max mm | stock bore sizes of the couplings | Mass kg | ||||

| A | B | C | D | E | ||||||

| CL035 | 16 | 20.2 | 7.8 | 6.5 | - | 0.5 | 30.000 | 9 | 8.9 | 0.03 |

| CL050 | 28 | 43 | 12 | 15.5 | - | 3 | 17.000 | 16 | 10.12.14.16 | 0.13 |

| CL070 | 35 | 50.7 | 12.7 | 19 | - | 5 | 13.000 | 19 | 10.12.14.16.18.19 | 0.24 |

| CL075 | 45 | 55 | 12.7 | 20.5 | - | 10 | 10.000 | 24 | 12.14.16.18.19.20.22.24 | 0.40 |

| CL090 | 54 | 55 | 12.7 | 21 | - | 16 | 9.000 | 25 | 14.16.18.19.20.22.24.25 | 0.68 |

| CL095 | 54 | 64 | 12.7 | 25.5 | - | 22 | 9.000 | 29 | 14.16.18.19.20.22.24.25.28 | 0.71 |

| CL099 | 65 | 73 | 19 | 27 | - | 45 | 7.000 | 35 | 20.22 24.25 28.30.32.35 | 1.22 |

| CL100 | 65 | 89 | 19 | 35 | - | 50 | 7.000 | 35 | 20.22 24.2528.30.32.35 | 1.40 |

| CL110 | 84 | 108 | 22 | 43 | - | 90 | 5.000 | 42 | 25.28.30.32 35.38.40.42 | 3.0 |

| CL150 | 96 | 115.4 | 25.4 | 45 | 80 | 150 | 5.000 | 48 | 30.32 35.38.40.42.45.48 | 5.0 |

| CL190 | 115 | 133.4 | 25.4 | 54 | 102 | 200 | 5.000 | 54 | 35.38.40.42.45.48.50 | 7.6 |

| CL225 | 127 | 153.4 | 25.4 | 64 | 108 | 300 | 4.200 | 67 | 38.40. 42.45 48.50.55.60.65 | 9.0 |

| CL276 | 157 | 200 | 41 | 79 | 127 | 542 | 4.200 | 73 | 45.48.50.55.60.65.70 | 21.0 |