Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

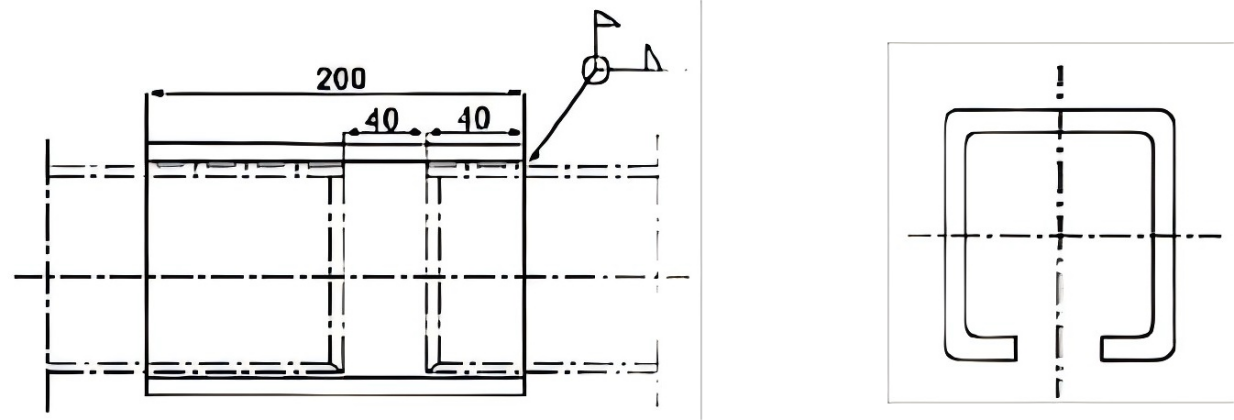

Temperature expansion joint

Product description

When the operating track traverses high-temperature zones like baking areas, temperature expansion connectors should be set up at both ends of the high-temperature segment. One end of the temperature expansion connector should be affixed to the track by welding, and the other end should feature a sliding sleeve. A proper space should be kept between the two tracks to make up for thermal deformation.

Performance characteristics:

Temperature adaptability:Wide temperature range: Designed for good operation in a broad temperature range, withstanding high and low temperatures for reliable performance in various industrial environments.

Precise temperature compensation: Accurately compensates for thermal expansion and contraction to maintain connected components in proper working state.

Mechanical properties:High strength and durability: Made of high-quality materials for strength and long service life, reducing replacement needs.

Stable and reliable connection: Provides a firm connection between system parts even with temperature changes.

Flexibility and mobility:Smooth expansion and contraction: Offers unrestricted expansion and contraction for seamless system operation during temperature fluctuations.

Axial and radial movement: Some joints can accommodate different directions of movement for added flexibility.

Sealing and insulation properties:Effective sealing: Prevents contaminants from entering and reduces corrosion risk.

Thermal insulation: Can provide insulation in some applications.

Application

In industrial production, it's used for lifting and transporting heavy machinery and equipment in manufacturing plants and handling materials in the metalworking industry.

In warehousing and logistics, it's for stacking and retrieving heavy pallets and loading/unloading heavy cargo.

On construction sites, it lifts and moves heavy construction materials and equipment.

It also has applications in the shipping and power generation industries. With its strong load-bearing capacity and reliable performance, it has a wide range of uses.

Performance advantages

Adapting to temperature changes:It can handle drastic temperature variations on conveyor lines, ensuring stable operation in different temperature environments.

Its precise temperature compensation mechanism adjusts length according to temperature changes, preventing track deformation and ensuring material transportation accuracy.

Ensuring smooth material transportation:Prevents jamming by providing smooth expansion and contraction, maintaining good track connections and enabling smooth material movement.

Reduces material blockage and accumulation, improving production efficiency.

Improving equipment service life:Absorbs thermal stress from temperature changes, reducing pressure on equipment and wear and deformation.

Prolongs the service life of conveyor line equipment and lowers maintenance and replacement costs.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: generally 15 workdays.

2.Production Lead-times: 30-60 workdays after getting your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

We'll show you the photos of the products and packages before you pay the balance.

Q4: What is your advantages?

1. Manufacturer,the most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

4. Rich stock and quick delivery.

Q5. If you can’t find the product on our website,what do you next?

Please send us inquiry with product pictures and drawings by email or other ways and we'll check.