Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

Temperature expansion rail

Product description

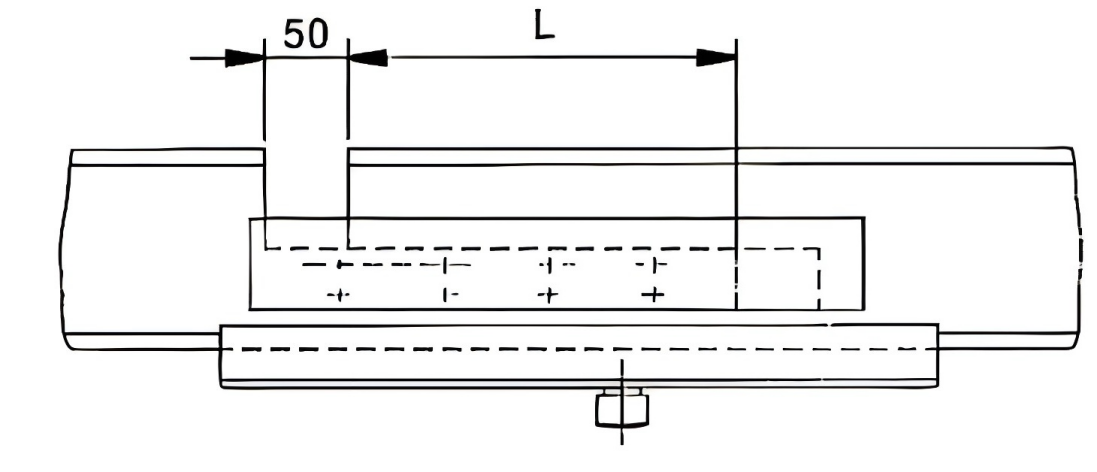

When the running track passes through high temperature sections such as baking, temperature expansion joints should be added at both ends of the high-temperature section. One end of the temperature expansion joint should be welded to the track, and the other end should be a sliding sleeve with the other track. Maintain an appropriate gap between the two rails to compensate for thermal deformation.

Performance characteristics:

Strong temperature adaptability: Works in a wide temperature range, ensuring stable operation of the conveyor line in different seasons and conditions.

High telescopic precision: Controls telescopic error within a small range for accurate material transportation, improving efficiency and quality.

Good stability: Maintains stability under temperature changes and material impacts, reducing failures and downtime and lowering maintenance costs.

Strong versatility: Has various specs and models, customizable for different conveyor lines and widely applicable.

Application

Food and beverage industry: Changes in ambient temperature affect production. The XT rail ensures stable operation, safeguarding processes and improving quality and efficiency.

Chemical industry: Complex temperature changes and corrosive materials. The XT rail is reliable due to its properties, ensuring safe transportation.

Logistics and warehousing industry: Temperature changes affect track performance. The XT rail maintains normal operation, improving speed and accuracy and reducing costs.

Working principle:

The XT temperature telescopic rail is equipped with a temperature sensor inside to monitor the changes of ambient temperature in real time. When the temperature rises or falls, the sensor transmits the signal to the control system. The control system drives the telescopic mechanism according to the preset program, making the rail automatically elongate or shorten, so as to always maintain the appropriate length of the rail to meet the needs of material transportation.

How to choose a suitable temperature expansion rail:

Temperature range:Clarify the working environment temperature and its variation range, and choose a telescopic rail that adapts to the temperature range and has good compensation ability.

Load-bearing capacity:Evaluate the weight of materials and dynamic load factors, and choose a telescopic rail with corresponding load-bearing capacity and reserved margin.

Telescopic precision:According to the material transportation precision and the overall precision requirements of the system, choose a telescopic rail with high telescopic precision.

Material and durability:According to the environmental corrosiveness and material friction situation, choose a material that is corrosion-resistant, wear-resistant and of reliable quality.

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: generally 15 workdays.

2.Production Lead-times: 30-60 workdays after getting your deposit.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery.

We'll show you the photos of the products and packages before you pay the balance.

Q4: What is your advantages?

1. Manufacturer,the most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

4. Rich stock and quick delivery.

Q5. If you can’t find the product on our website,what do you next?

Please send us inquiry with product pictures and drawings by email or other ways and we'll check.