Hot Keywords:

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Product Description

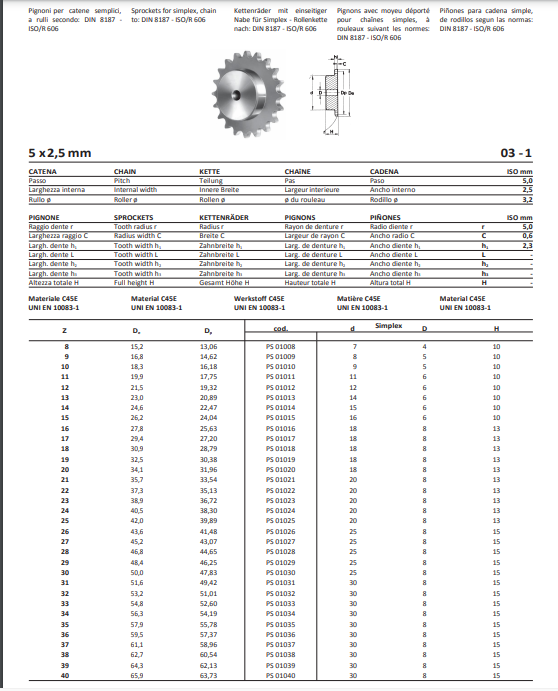

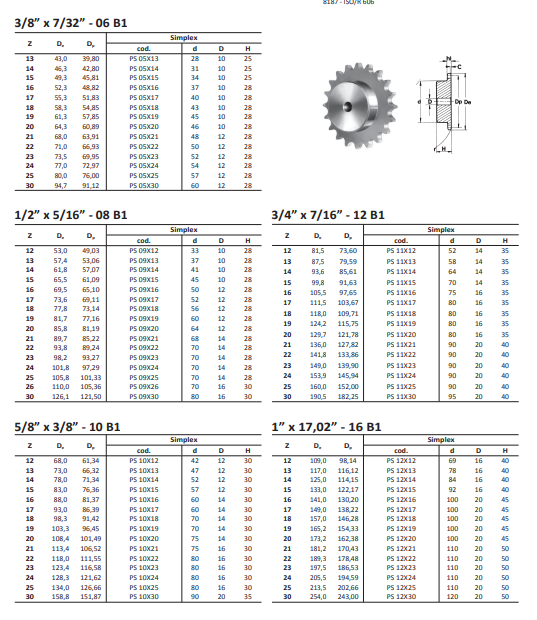

5×2,5 mm (ISO 03-1)

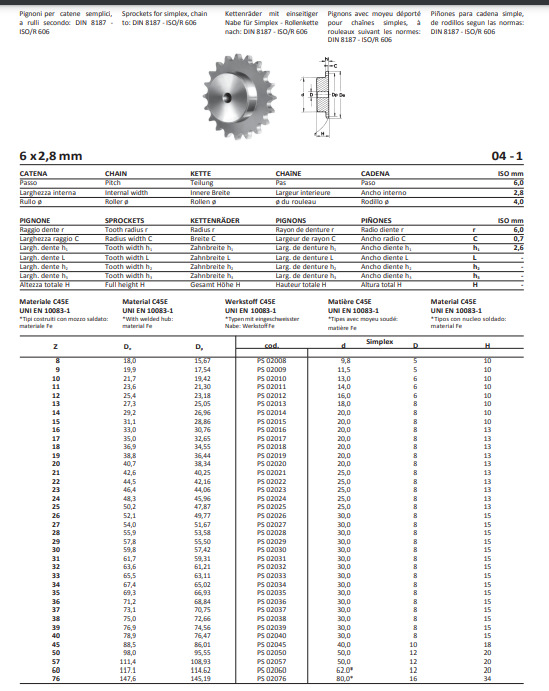

6×2,8 mm (ISO 04-1)

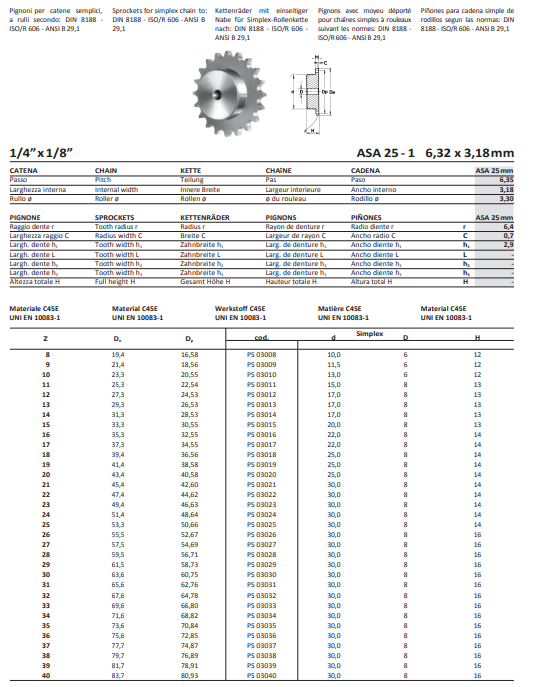

1/4″x1/8” (ASA 25-1)

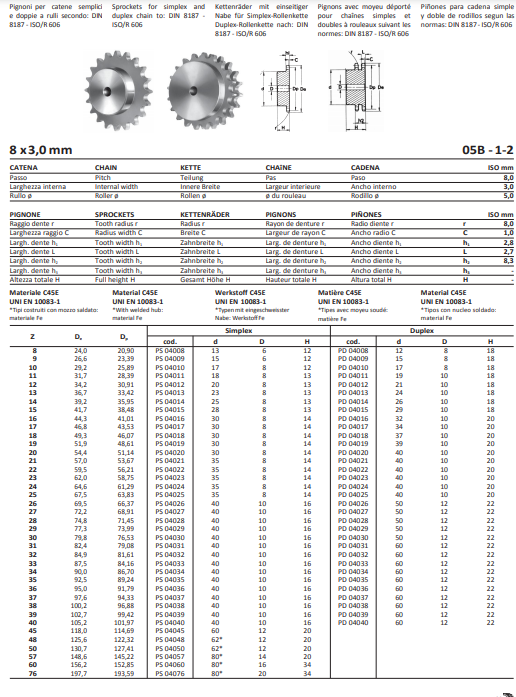

8×3 mm (ISO 05B-1; 05B-2)

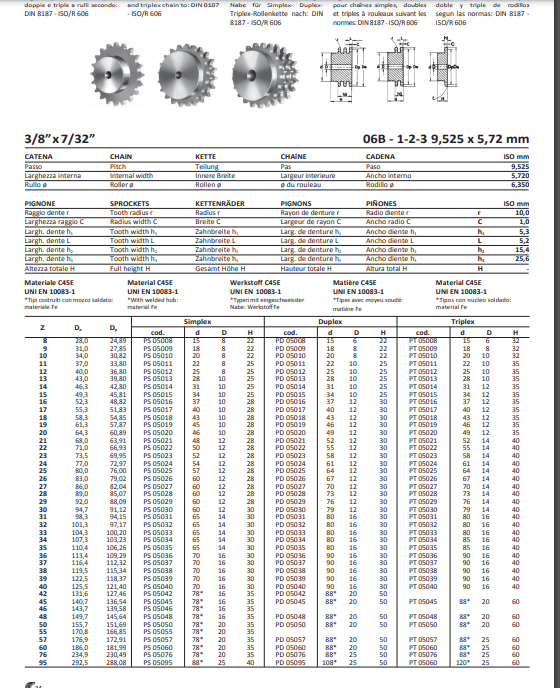

3/8”x7/16” (ISO 06B-1; 06B-2; 06B-3)

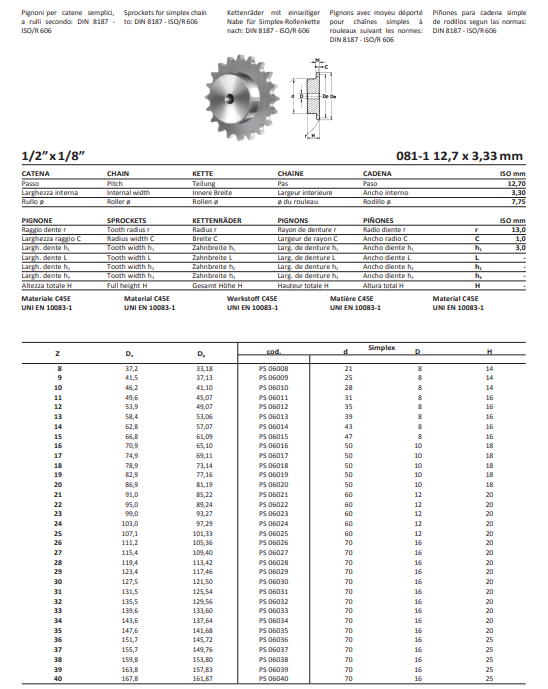

1/2″x1/8” (ISO 081-1)

1/2″x3/16” (ISO 083-1; ISO 084-1)

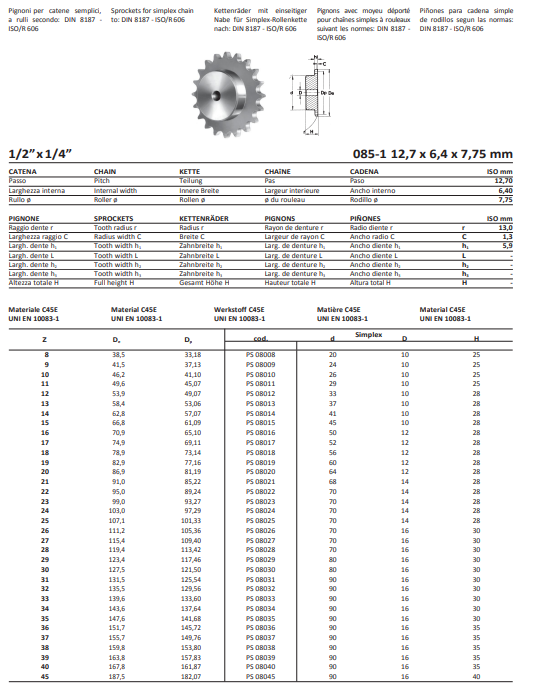

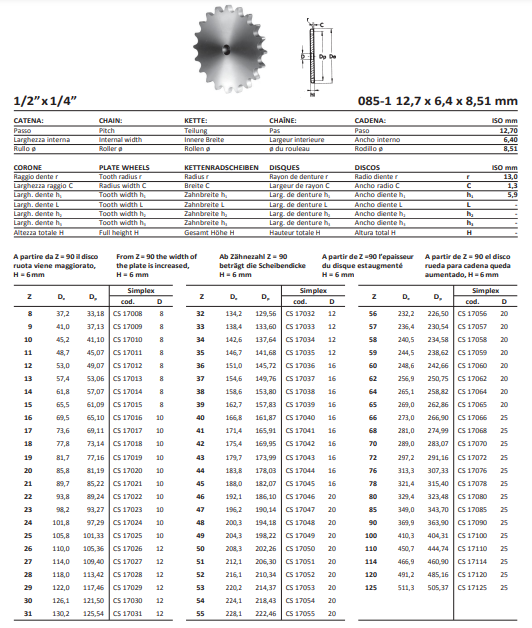

1/2″x1/4” (ISO 085-1) roller Ø7,75 and 8,51

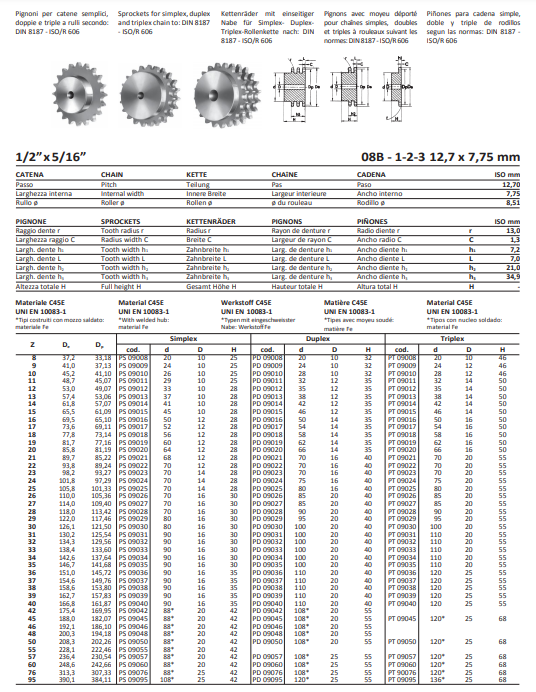

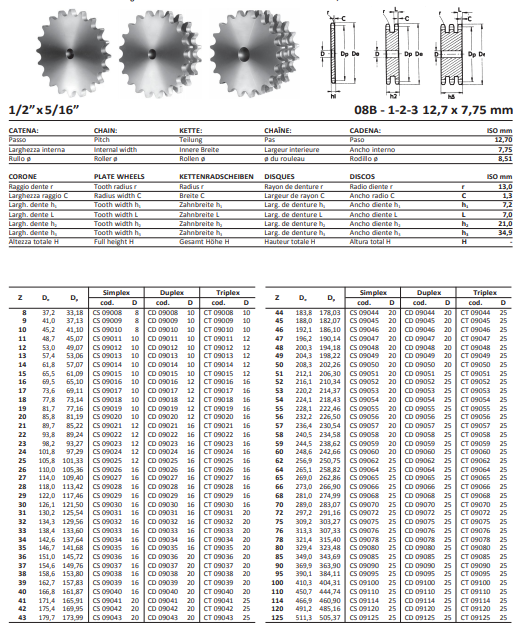

1/2″x5/16” (ISO 08B-1; ISO 08B-2; ISO 08B-3)

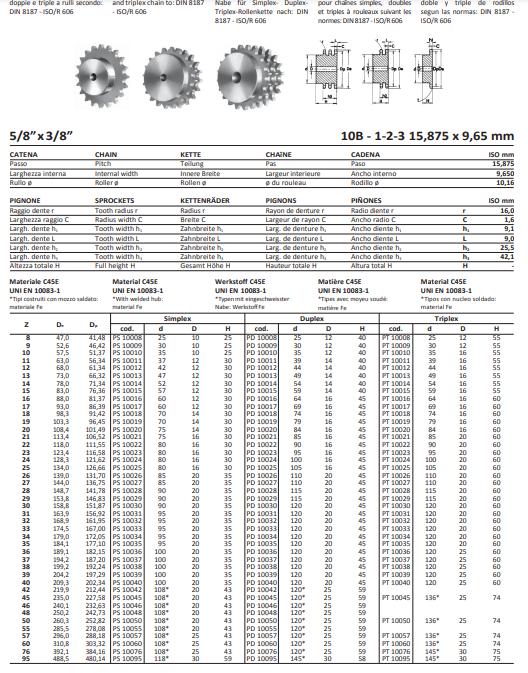

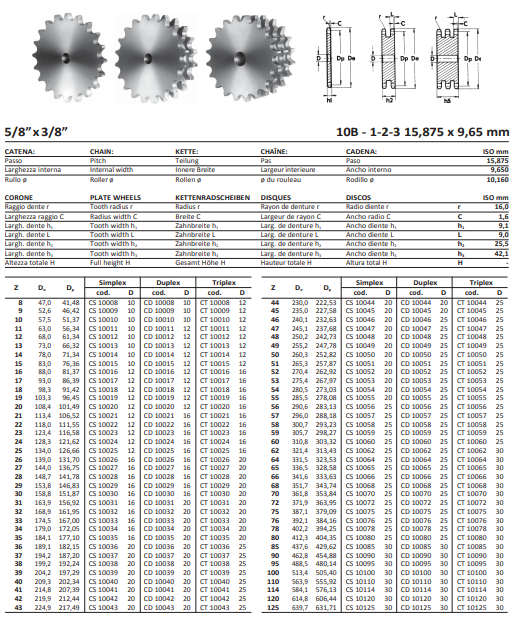

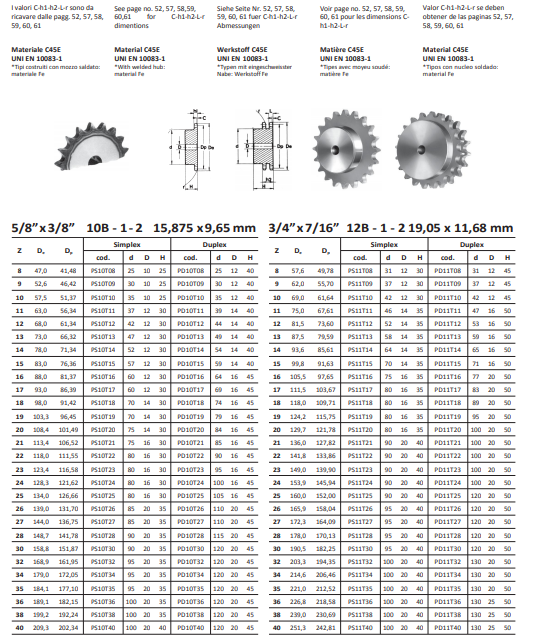

5/8”x3/8” (ISO 10B-1; 10B-2; 10B-3)

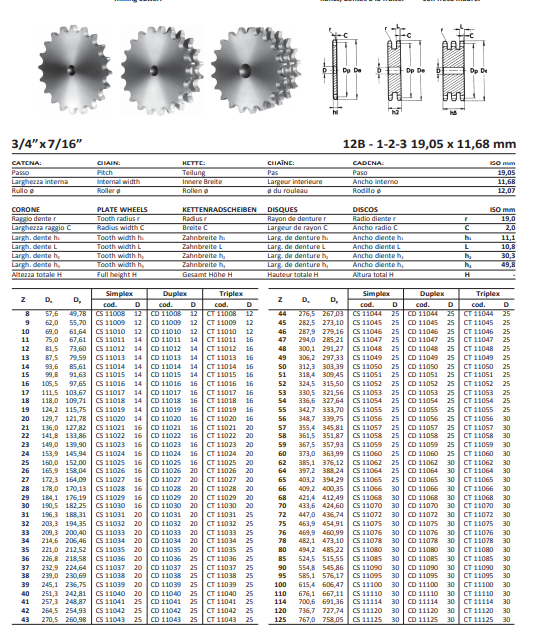

3/4″x7/16” (ISO 12B1; 12B2; 12B-3)

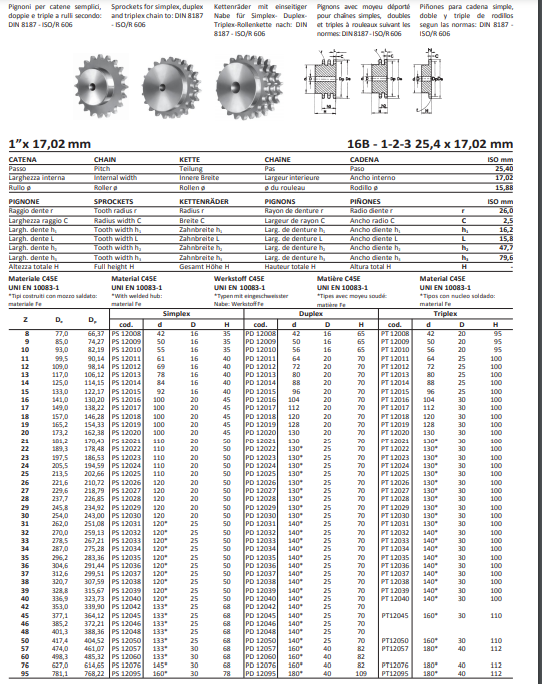

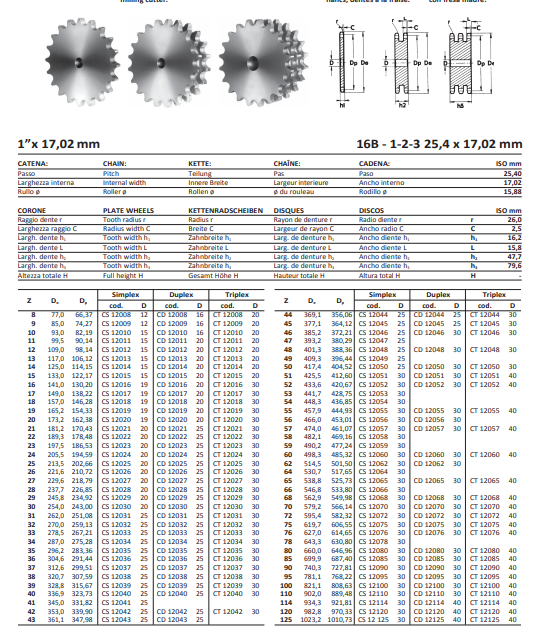

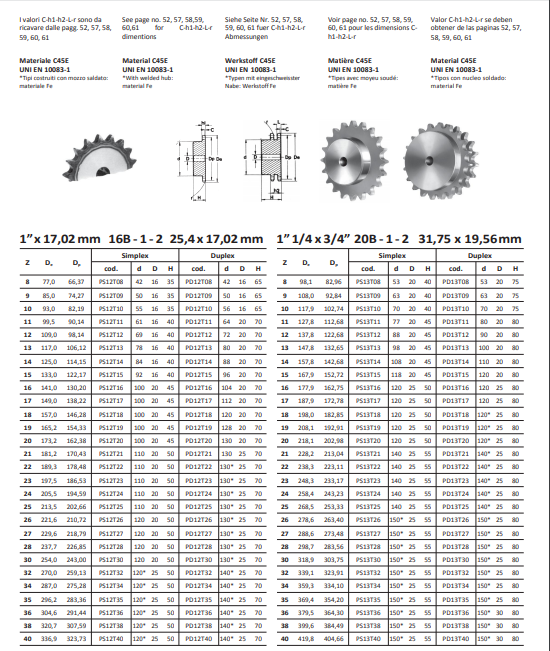

1”x17,02 mm (ISO 16B-1; 16B-2; 16B-3)

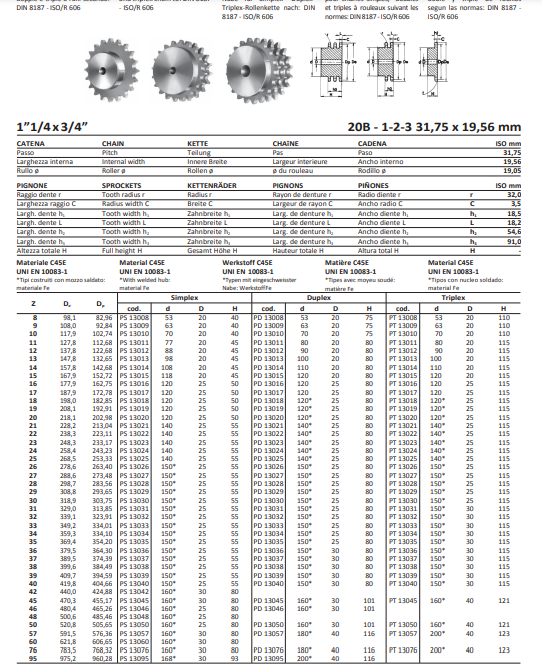

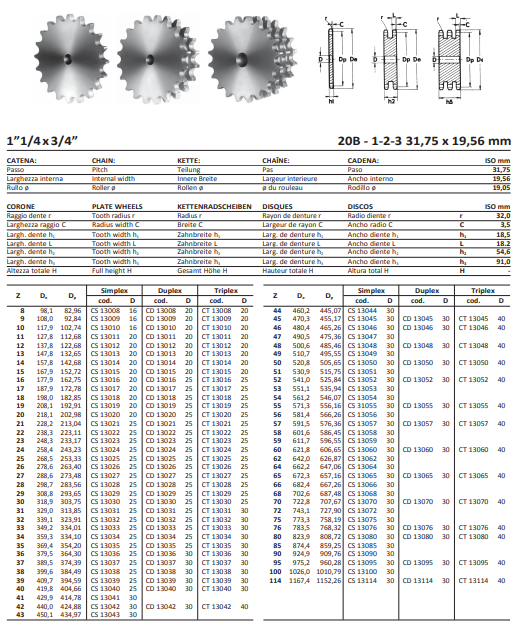

1”1/4×3/4” (ISO 20B-1; 20B-2; 20B-3)

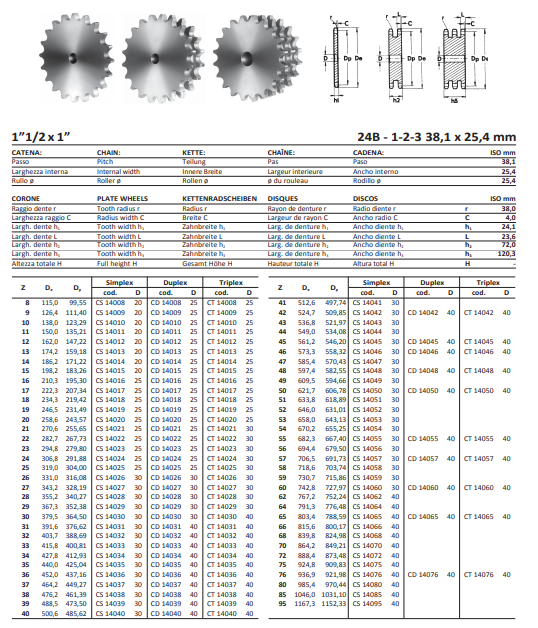

1”1/2×1” (ISO 24B-1; 24B-2; 24B-3)

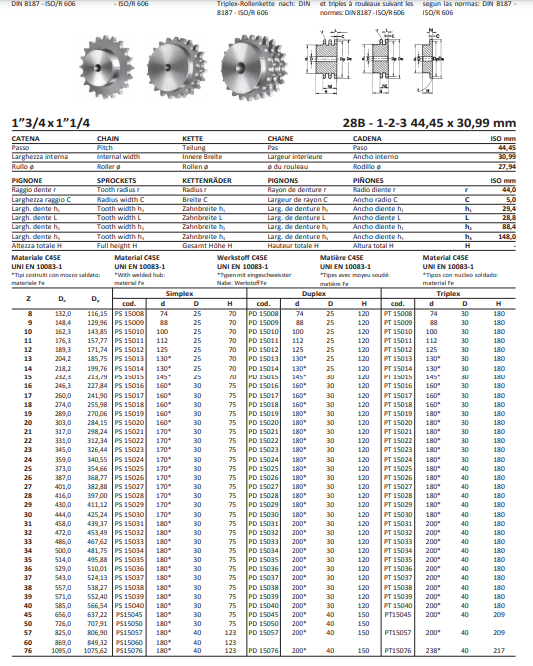

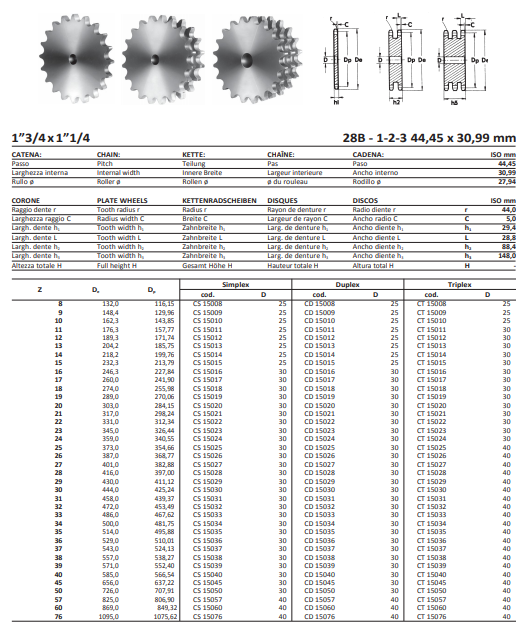

1”3/4×1”1/4 (ISO 28B-1; 28B-2; 28B-3)

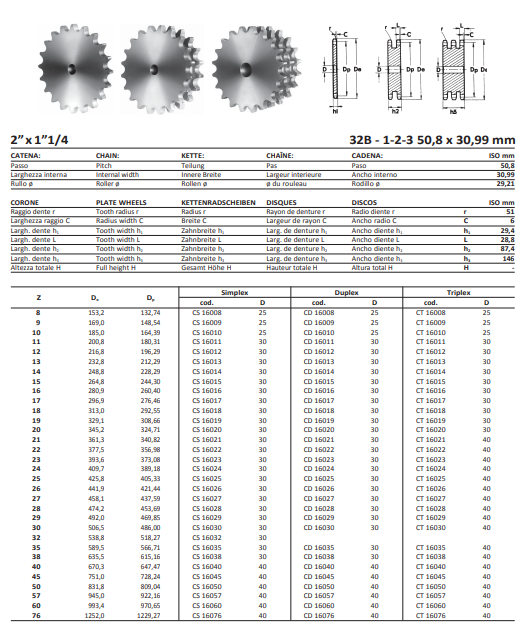

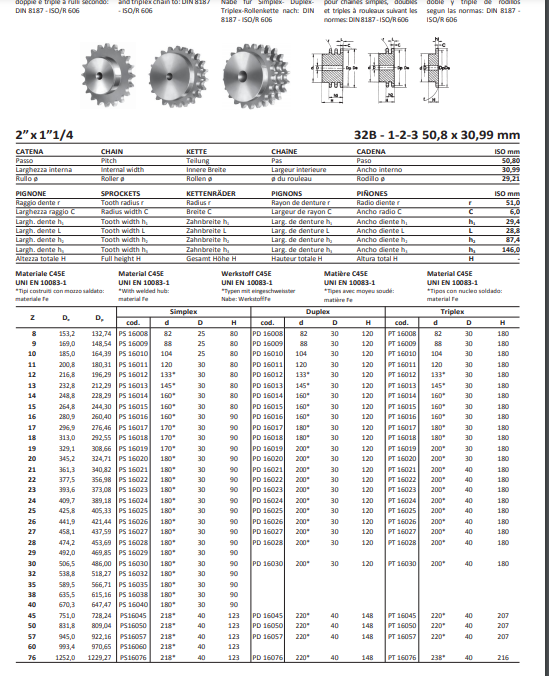

2”x1”1/4 (ISO 32B-1; 32B-2; 32B-3)

3/8”x3/16” (ASA 35-1; ASA 35-2; ASA 35-3)

1/2″x5/16” (ASA 40-1; ASA 40-2; ASA 40-3)

5/8”x3/8” (ASA 50-1; ASA 50-2; ASA 50-3)

3/4″x1/2” (ASA 60-1; ASA 60-2; ASA 60-3)

1”x5/8” (ASA 80-1; ASA 80-2; ASA 80-3)

1”1/4×3/4” (ASA 100-1; ASA 100-2; ASA 100-3)

1”1/2×1” (ASA 120-1; ASA 120-2; ASA 120-3)

1”3/4×1”1/4 (ASA 140-1; ASA 140-2; ASA 140-3)

2”x1”1/4 (ASA 160-1; ASA 160-2; ASA 160-3)

Different teeth numbers are available for every pitch.

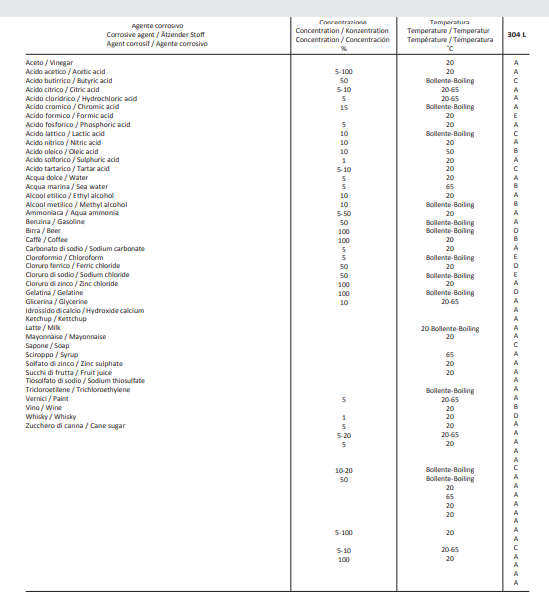

Furthermore, in order to meet all customers’ requirements, various materials (steel C45 E UNI EN 10083-1 and stainless steel AISI 304) are available. Surface treatments such as hardened teeth(45-55 HRC) can be also carried out for a better wear resistance of the product.